A kind of thermal conductivity flame retardant and preparation method thereof

A technology of flame retardants and additives, which is applied in the field of thermally conductive flame retardants and their preparation, can solve the problems of insufficient heat conduction and flame retardancy, and achieve good heat conduction effects, good heat conduction, and good compatibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The invention provides a method for preparing a heat-conducting flame retardant, which comprises the following steps:

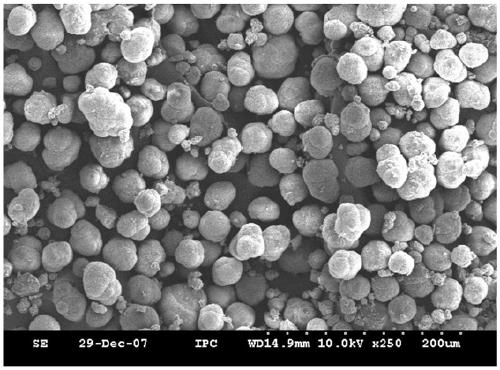

[0021] (a) Weigh the main material, auxiliary material and first auxiliary agent, and mix the main material, auxiliary material and first auxiliary agent at a first temperature to obtain a preform, wherein the main material includes spherical magnesium hydroxide and Fibrous structure, the mass ratio of spherical magnesium hydroxide to fibrous structure is 5:1~20:1;

[0022] (b) mixing the preform and the second auxiliary agent at a second temperature and drying to obtain the thermally conductive flame retardant.

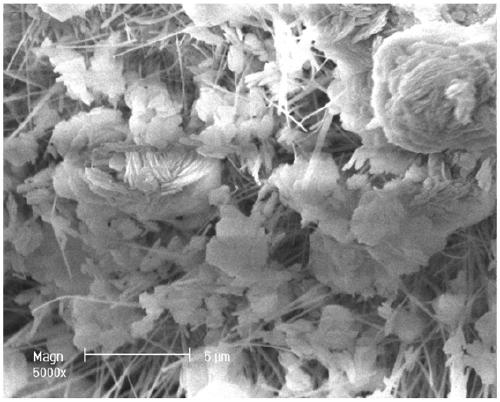

[0023] In step (a), the purpose of introducing the fibrous structure into the main material is to use the special structure of the fibrous structure to overlap a plurality of spherical magnesium hydroxide to form a spherical needle-shaped heat conduction system, which It has good heat conduction effect. The fibrous structure is one or more ...

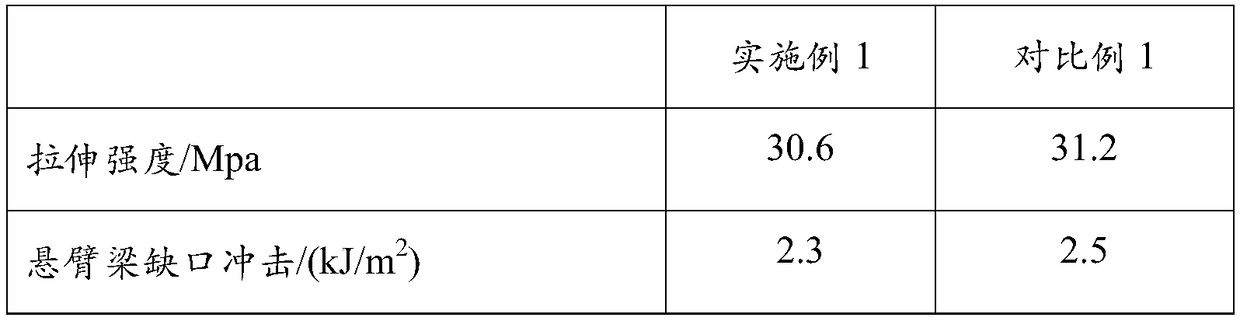

Embodiment 1

[0037] Weigh the main material, auxiliary material and first auxiliary agent, and mix the main material, auxiliary material and first auxiliary agent in a high-speed mixer at about 80 degrees Celsius to obtain a preform, wherein the main material includes spherical magnesium hydroxide and acicular magnesium hydroxide, the mass ratio of spherical magnesium hydroxide to acicular magnesium hydroxide is 20:1, the auxiliary material is wollastonite, the first auxiliary agent is polysiloxane, the main material and auxiliary material The mass ratio is 85:15, and the mass of the first auxiliary agent is 5% of the total mass of the main material and the auxiliary material.

[0038] The preform and the second additive are mixed and dried at about 115 degrees Celsius to obtain the thermally conductive flame retardant. Wherein, the second auxiliary agent is vinyl silane, and the mass of the second auxiliary agent is 5% of the total mass of the main material and the auxiliary material.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com