Biodegradable plastic film

A plastic film and biodegradable technology, applied in the field of degradable plastic film, can solve the problems of white pollution, long degradation time of plastic film, cotton production reduction, etc., and achieve the effect of good light transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

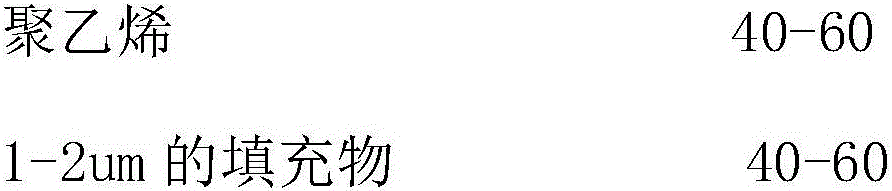

[0021] Biodegradable plastic film, described film is made of masterbatch through blown film, and described masterbatch comprises following material and parts by weight:

[0022]

[0023] Described filler comprises following material and parts by weight:

[0025] cornmeal 42

[0026] Described corn flour is through hydrophobization treatment, and concrete process is as follows:

[0027] Add the hydrophobic modifier to the crushed corn flour while stirring, and modify it at room temperature for 1 hour; the weight ratio of corn flour to hydrophobic modifier is 100:1;

[0028] The hydrophobic modifier is a silane coupling agent, the model is kh550, produced by Nanjing Chuangshi Chemical Auxiliary Co., Ltd.

[0029] The degradation agent is 4-(1-hydroxyl-1-methylethyl)-2-propyl-1H-imidazole-5-carboxylic acid ethyl ester, 2-phenylamino-3-methyl-6-di Butylfluoran, mixture of triacetyl resveratrol, ethyl 4-(1-hydroxy-1-methylethyl)-2-propyl-1H-imid...

Embodiment 2

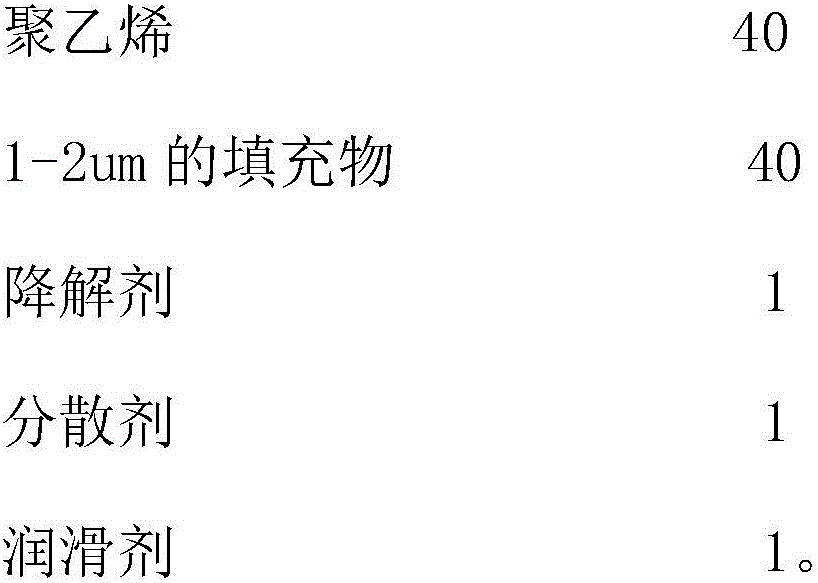

[0034] Biodegradable plastic film, described film is made of masterbatch through blown film, and described masterbatch comprises following material and parts by weight:

[0035]

[0036]

[0037] Described filler comprises following material and parts by weight:

[0039] Cornmeal 45

[0040] Described corn flour is through hydrophobization treatment, and concrete process is as follows:

[0041] After stirring the crushed corn flour, add the hydrophobic modifier and modify it at room temperature for 1.5 hours; the weight ratio of corn flour to hydrophobic modifier is 100:1.5;

[0042] The hydrophobic modifier is a silane coupling agent, the model is kh550, produced by Nanjing Chuangshi Chemical Auxiliary Co., Ltd.

[0043] The degradation agent is 4-(1-hydroxyl-1-methylethyl)-2-propyl-1H-imidazole-5-carboxylic acid ethyl ester, 2-phenylamino-3-methyl-6-di Butylfluoran, mixture of triacetyl resveratrol, ethyl 4-(1-hydroxy-1-methylethyl)-2-...

Embodiment 3

[0048] Biodegradable plastic film, described film is made of masterbatch through blown film, and described masterbatch comprises following material and parts by weight:

[0049]

[0050] Described filler comprises following material and parts by weight:

[0052] cornmeal 40

[0053] Described corn flour is through hydrophobization treatment, and concrete process is as follows:

[0054] Add the hydrophobic modifier to the crushed corn flour while stirring, and modify it at room temperature for 2 hours; the weight ratio of corn flour to hydrophobic modifier is 100:2;

[0055] The hydrophobic modifier is a silane coupling agent, the model is kh550, produced by Nanjing Chuangshi Chemical Auxiliary Co., Ltd.

[0056] The degradation agent is 4-(1-hydroxyl-1-methylethyl)-2-propyl-1H-imidazole-5-carboxylic acid ethyl ester, 2-phenylamino-3-methyl-6-di Butylfluoran, mixture of triacetyl resveratrol, ethyl 4-(1-hydroxy-1-methylethyl)-2-propyl-1H-imi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com