Thermally conductive silicone putty composition

A technology of silicone oil and thermal conductivity, which is applied in the field of thermal conductive silicone putty composition, can solve the problems of misoperation of components, insufficient heat removal, insufficient performance, etc., and achieve the effect of improving offset resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5、 comparative example 1~10

[0080] As shown in Tables 1, 2, and 3, each component was put into a planetary mixer (numbers in the table indicate g), and uniformly mixed at 25° C. for 30 minutes to prepare a heat-conductive putty composition. Using the obtained composition, various tests described above were performed. The results are described in Tables 1, 2, and 3 together. In addition, the components (A)-(F) used are as follows.

[0081] ingredient (A)

[0082] (A-1)

[0083] Both ends are capped with trimethylsilyl groups, linear, kinematic viscosity 1,000mm 2 / s of dimethyl polysiloxane.

[0084] (A-2)

[0085] Both ends are terminated with trimethylsilyl groups, linear, kinematic viscosity 5,000mm 2 / s of dimethyl polysiloxane.

[0086] (A-3)

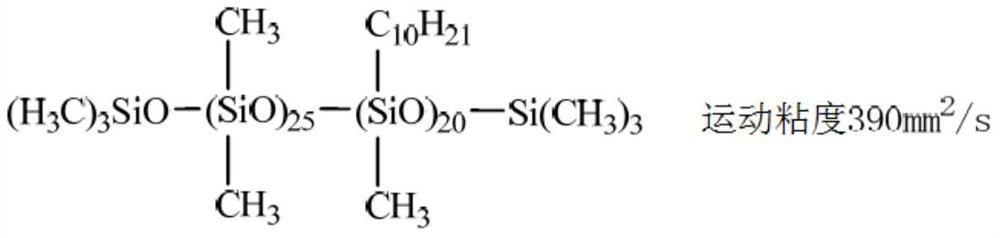

[0087] 【Chemical 3】

[0088]

[0089] ingredient (B)

[0090] (B-1)

[0091] A dimethylpolysiloxane raw rubber having a vinyl group at both terminals and having an absolute viscosity at 25°C of 11,000 mPa·s at 30% by mass in xylene was dissolv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com