Diamond micro-powder aggregate preparation method using magnesia as binder

A technology of diamond micropowder and magnesite, which is applied to chemical instruments and methods, and other chemical processes, can solve problems such as limited service life, reduce binder volume, and large specific surface area, so as to improve service life and efficiency, improve The effect of environmental protection level and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

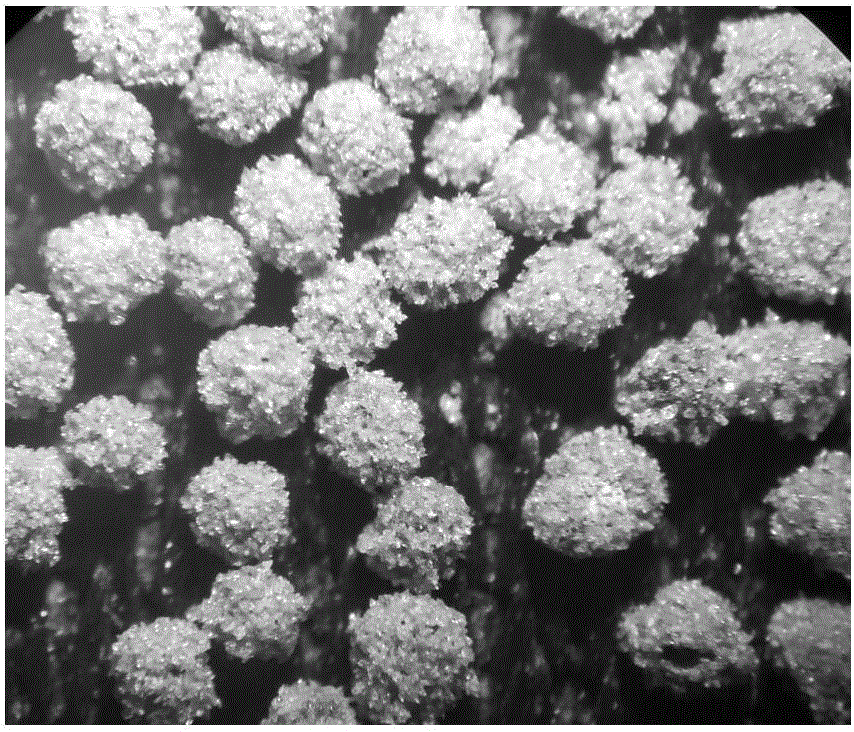

Image

Examples

Embodiment 1

[0023] A 0.8 mm pellet was prepared. Its preparation method is as follows:

[0024] step 1):

[0025] a According to the formula of MgCl2: 30 grams, phosphoric acid 3ml, deionized water 100ml, add MgCl2 and phosphoric acid into deionized water in turn, stir until there are no particles, and then make curing agent A.

[0026] b According to the ratio of MgCl2: 40g, phosphoric acid 5ml, and deionized water 100ml, add MgCl2 and phosphoric acid into deionized water in turn, stir until there are no particles, and then make curing agent B.

[0027] c Select 50 grams of diamond single crystal with an average particle size of 0.1 μm, add it to curing agent A and soak for 12 hours (based on the diamond submerged in curing agent A), remove and control to dry for later use.

[0028] Step (2):

[0029] The calcined magnesite and the soaked diamond powder are mixed according to the mass ratio of calcined magnesite:diamond powder=1:1 to form a mixed powder for later use, wherein the part...

Embodiment 2

[0039] A 1.0 mm pellet was prepared. The method for preparing curing agent A and B is the same as in Example 1; wherein the primary aggregates are crushed by natural drying and slightly dry wet material blocks and pass through 14 mesh sieves and remain on 16 mesh sieves, and the average aggregate particle diameter is about 1.0mm; basic aggregates are also sieved in the same way; the rest are the same as in Example 1.

Embodiment 3

[0041] A 1.6 mm pellet was prepared. The method for preparing curing agent A and B is the same as in Example 1; wherein in step (2), calcined magnesite and soaked diamond micropowder are mixed according to mass ratio=1:2 to become mixed powder, and the others are the same; the primary aggregate is Crushed by natural drying and micro-drying wet mass and passed through a 10 mesh sieve and remaining on a 12 mesh sieve, the average particle size of the aggregate is about 1.6mm; the basic aggregate is also sieved in the same way;

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com