Oil agent for spinning of viscose staple fibers

A technology of viscose staple fiber and oil agent, applied in the direction of fiber type, fiber treatment, plant fiber, etc., can solve the problems of restricting the development of viscose fiber industry, high application cost, strong technical constraints, etc., and achieve stable product quality, The effect of low production cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] An oil agent for viscose staple fiber spinning, which is composed of the following compositions by weight: 18 parts of F and 82 parts of S.

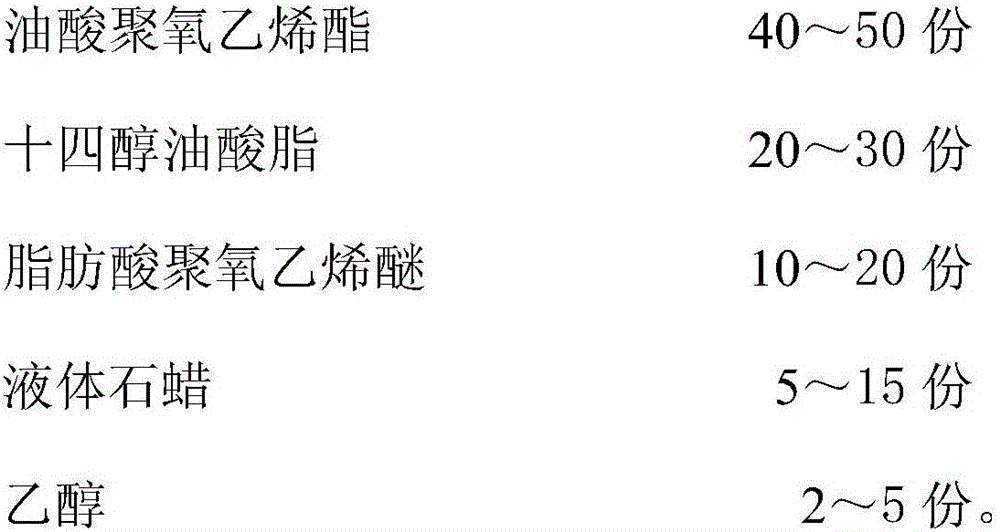

[0035] Wherein composition F is made up of following components by weight:

[0036]

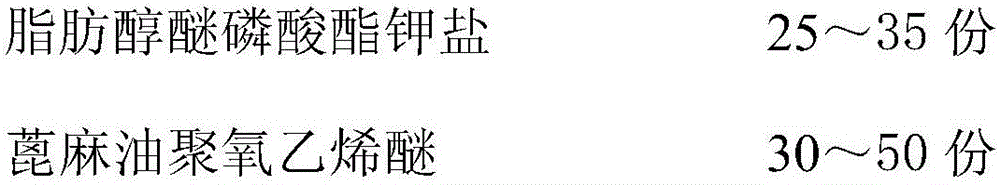

[0037] Wherein composition S is made up of following components by weight:

[0038]

Embodiment 2

[0040] An oil agent for viscose staple fiber spinning, which is composed of the following compositions by weight: 25 parts of F and 75 parts of S.

[0041] Wherein composition F is made up of following components by weight:

[0042]

[0043]

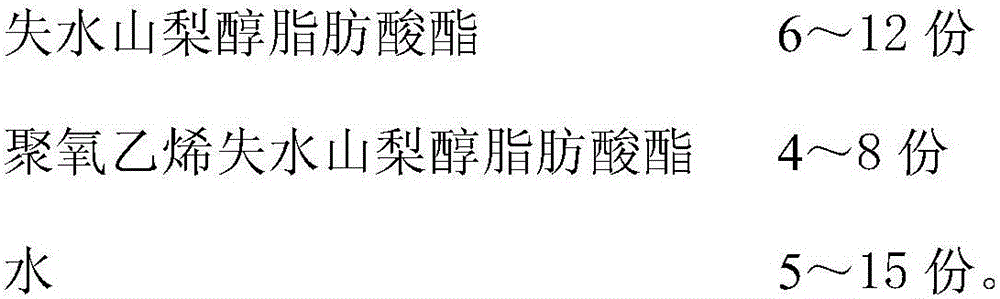

[0044] Wherein composition S is made up of following components by weight:

[0045]

Embodiment 3

[0047] An oil agent for viscose staple fiber spinning, which is composed of the following compositions by weight: 30 parts of F and 70 parts of S.

[0048] Wherein composition F is made up of following components by weight:

[0049]

[0050] Wherein composition S is made up of following components by weight:

[0051]

[0052]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com