A dense column system for prefabricated concrete houses

A concrete and prefabricated technology, which is applied in the direction of basic structure engineering, architecture, building structure, etc., can solve the problems of low degree of mechanization and large wet work on site, and achieve simple node structure and force transmission, convenient assembly construction, and force bearing reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

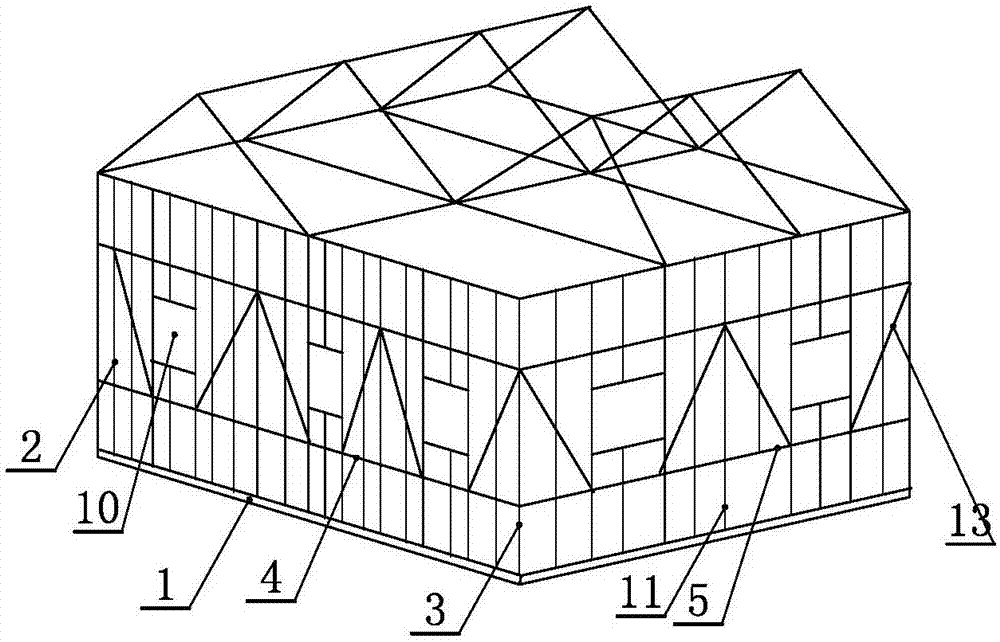

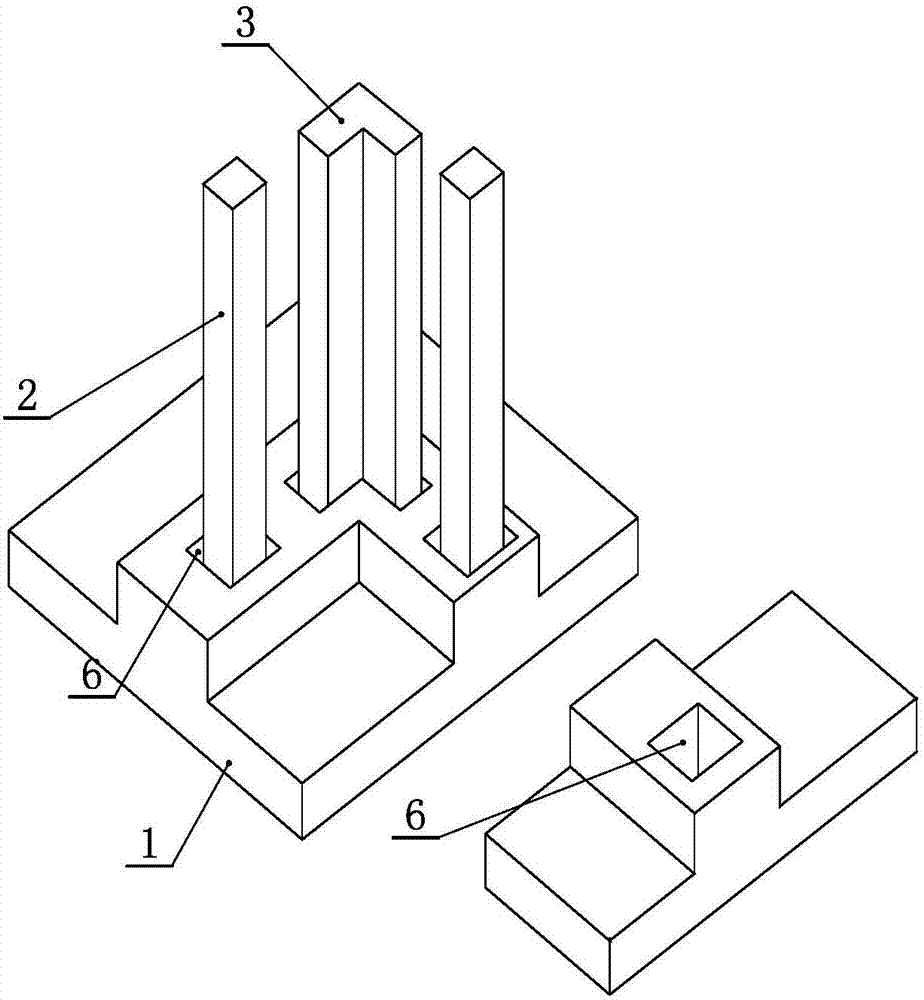

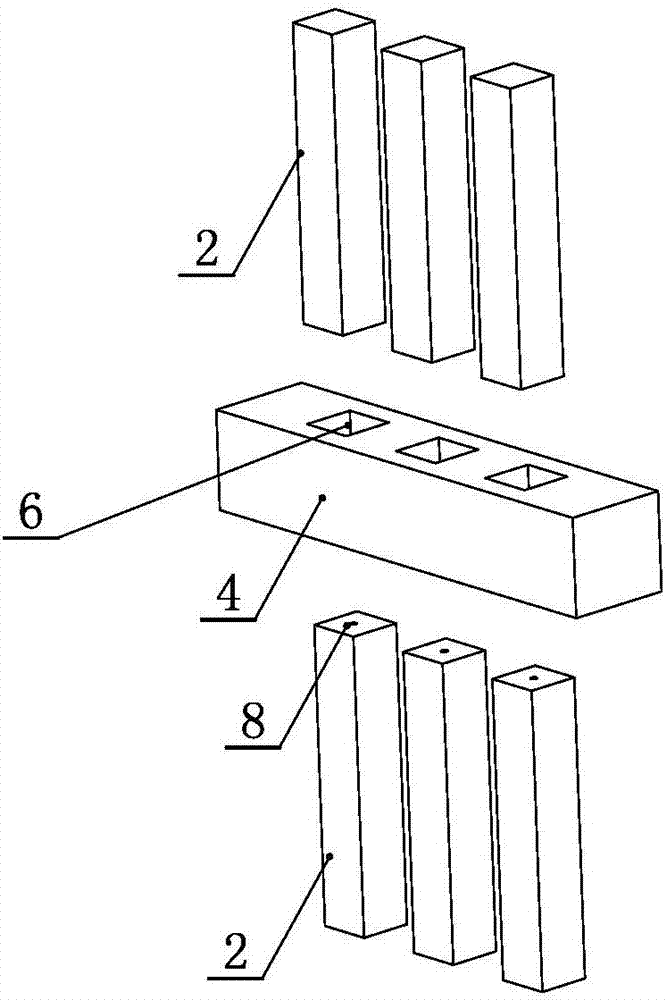

[0029] The following is attached Figure 1-5 The features and principles of the present invention are described in detail, and the examples given are only used to explain the present invention, not to limit the protection scope of the present invention.

[0030] like Figure 1-Figure 5 As shown, the invention includes a prefabricated strip foundation with a cup opening 1, a square prefabricated concrete wall column 2, a special-shaped precast concrete corner column 3, a prefabricated concrete beam 4, a prefabricated concrete staircase, a reinforced concrete composite slab floor, a composite slab roof and a prefabricated tiger Windows, square prefabricated concrete wall columns are sprayed with light slurry to form a load-bearing wall, the outer side of the load-bearing wall is installed with thermal insulation and decorative integrated board, and the inner side of the load-bearing wall is installed with gypsum board.

[0031] Special-shaped precast concrete corner columns inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com