An analytical method for rapid joint measurement of ni and other elements in flash smelting slag

A technology of flash smelting and analysis method, which is applied in the field of chemical analysis and detection, can solve the problem that the element standard curve is not linear, and achieve the effects of fast detection and analysis, fast determination, and fast sample preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

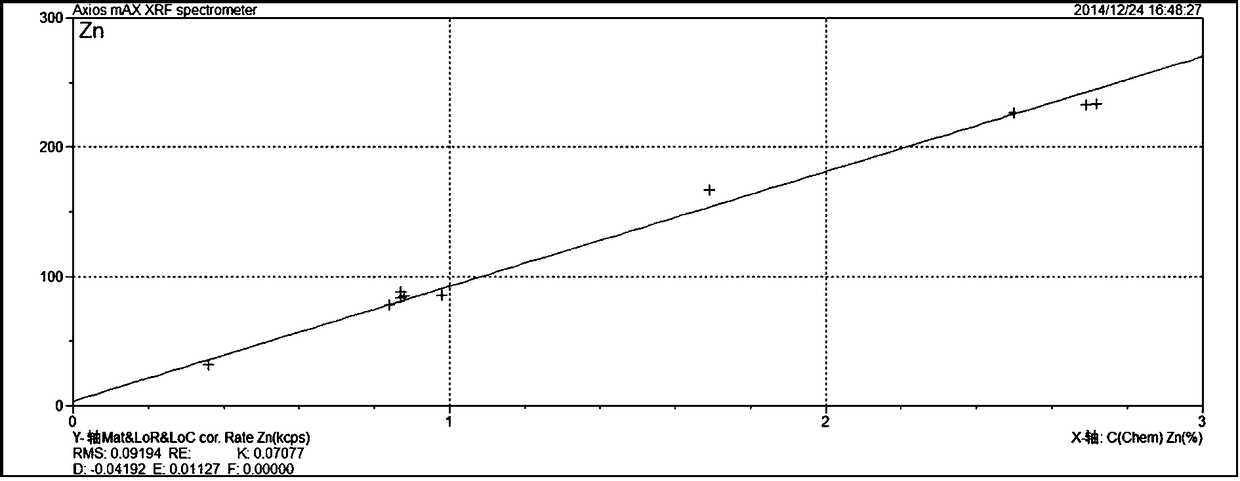

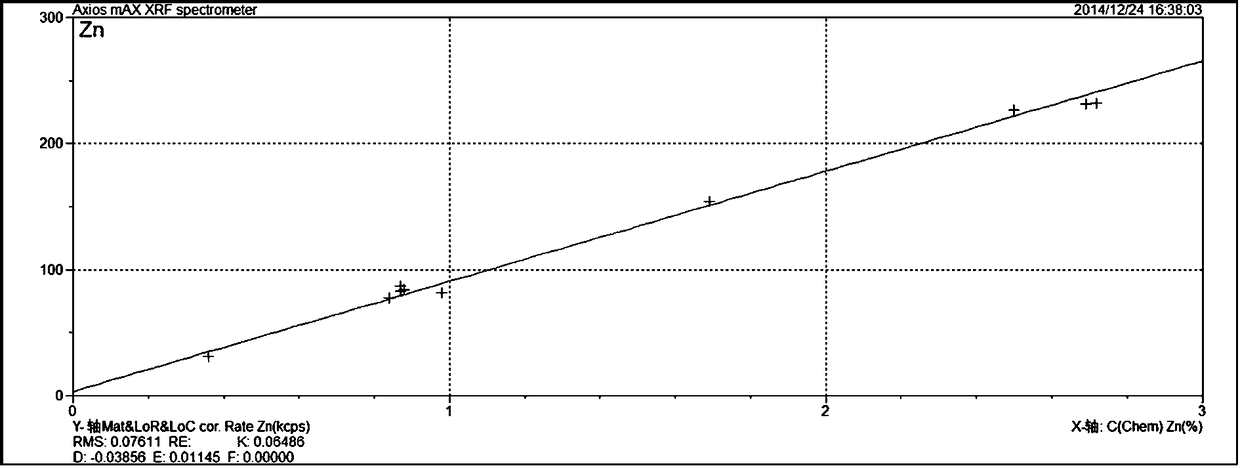

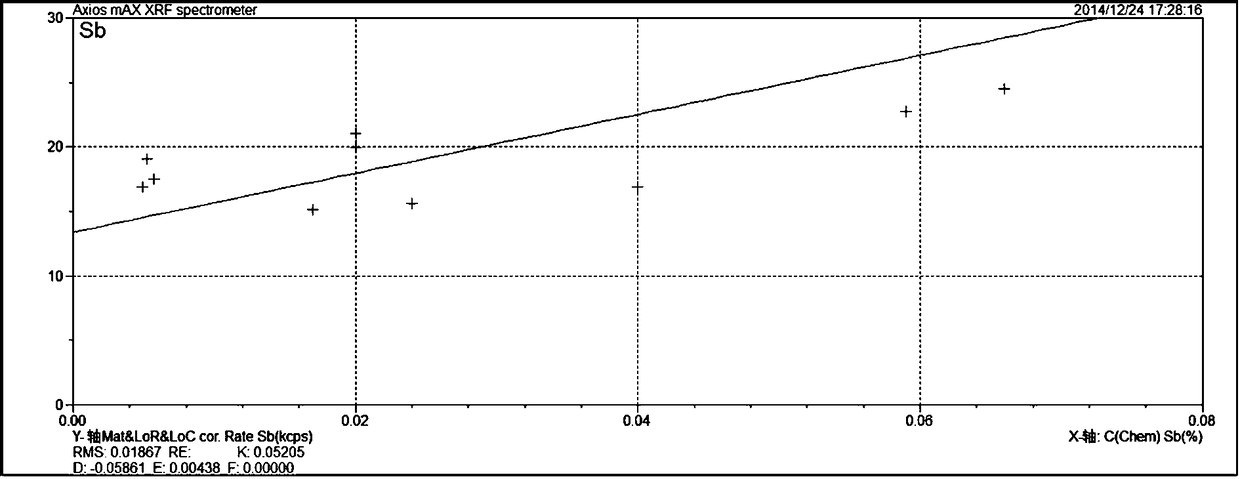

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0037] The present invention is a rapid joint measurement of Ni, Cu, Fe, S, CaO, MgO, SiO in flash smelting slag 2 , Pb, Zn, As, Sb, Bi's analytical method This method is carried out according to the following steps:

[0038] 1) Preparation of samples: first, sample grinding, put 100-150g of flash smelting slag into the grinding plate of the sample pulverizer and grind for 50-60s, and put the ground samples into coded sample bags; 2. Sample pressing, put the sample mold into the sample press, take out 4g~6g of the sample from the coded sample bag with a horn spoon and put it into the sample mold, use industrial boric acid to trim the bottom of the sample mold, and the press maintains the pressure Under the conditions of 25-28T and holding time of 25-30s, the sample is made into a sample piece with a diameter of 32mm, and the industrial boric...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com