Preparation method of roflumilast N-oxide

A technology of roflumilast and compounds, which is applied in the field of preparation of roflumilast N-oxide, can solve the problems of high price, long reaction time, low yield, etc., and achieve convenient post-processing, high product purity, and reaction The effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

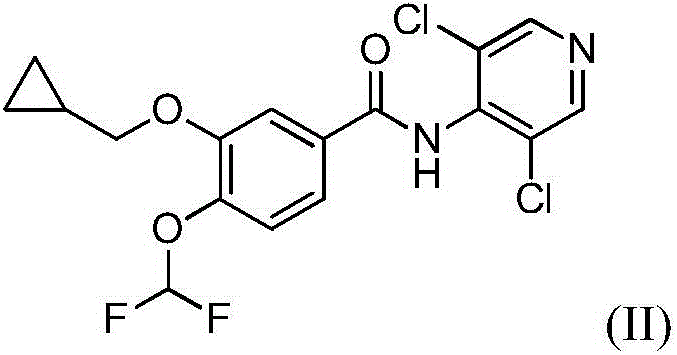

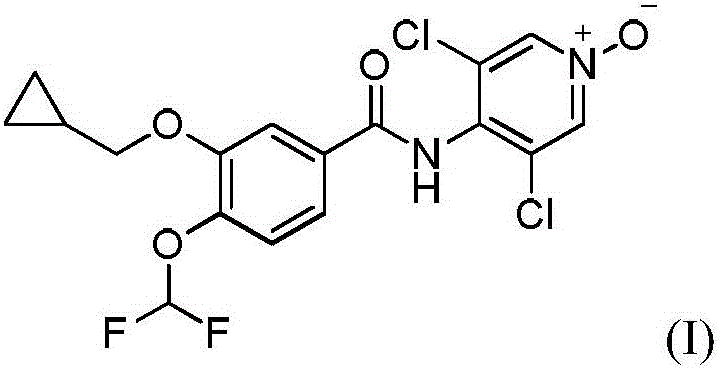

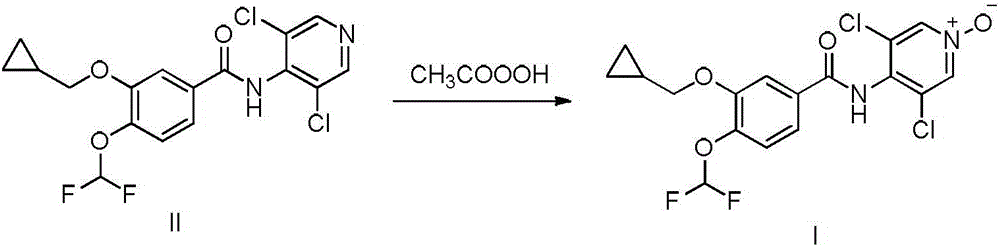

Image

Examples

Embodiment 1

[0049] Preparation of Roflumilast N-oxide

[0050]

[0051]Add roflumilast (5 g, 12.4 mmol), acetic acid (24 mL), and 30% hydrogen peroxide (6.3 mL, 62 mmol) into a three-necked reaction flask, heat up to 70° C. and stir for 6 hours. After the reaction was completed, cool to room temperature, pour the reaction solution into 150 mL ice water, add sodium carbonate to adjust the pH value to 7-8, and extract the aqueous phase with ethyl acetate (150 mL×3). The organic phases were combined, dried over anhydrous sodium sulfate, filtered, and concentrated to obtain roflumilast N-oxide (HPLC purity 96.9%).

[0052] Recrystallization:

[0053] The obtained product roflumilast N-oxide was added into isopropanol (50 mL), heated to 80° C. under stirring, and dissolved completely in about 20 minutes, and continued to stir for 30 minutes. The solution was naturally cooled to room temperature, a white solid was precipitated, filtered with suction, and the filter cake was washed with col...

Embodiment 2

[0057] Preparation of Roflumilast N-oxide

[0058] Roflumilast (5g, 12.4mmol), acetic acid (24mL), and 30% hydrogen peroxide (6.3mL, 62mmol) were added into the reaction flask, heated to 30°C and stirred for 133 hours. After the reaction is completed, cool the reaction liquid, pour it into 150 mL of ice water, add sodium carbonate to adjust the pH to 7-8, extract the aqueous phase with ethyl acetate (150 mL×3), combine the organic phases, dry over anhydrous sodium sulfate, and filter , concentrated to obtain roflumilast N-oxide (HPLC purity 92.9%).

[0059] Referring to the recrystallization method in Example 1, the purified white solid roflumilast N-oxide (4.0 g, yield 76.9%, HPLC purity 95.1%) was obtained through recrystallization.

Embodiment 3

[0061] Preparation of Roflumilast N-oxide

[0062] Add roflumilast (5 g, 12.4 mmol), acetic acid (24 mL), and 30% hydrogen peroxide (6.3 mL, 62 mmol) into the reaction flask, heat up to 40° C. and stir for 83 hours. After the reaction is completed, cool the reaction solution to room temperature, pour it into 150 mL of ice water, add sodium carbonate to adjust the pH to 7-8, extract the aqueous phase with ethyl acetate (150 mL×3), combine the organic phases, and dry over anhydrous sodium sulfate , filtered and concentrated to obtain roflumilast N-oxide (HPLC purity 95.1%).

[0063] Referring to the recrystallization method in Example 1, the purified white solid roflumilast N-oxide (4.2 g, yield 80.8%, HPLC purity 96.4%) was obtained through recrystallization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com