An evaluation device and evaluation method for the degradation effect of photocatalytic materials on PM2.5

A technology for photocatalytic materials and evaluation devices, which can be used in measurement devices, analytical materials, instruments, etc., and can solve problems such as large differences in open space states.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

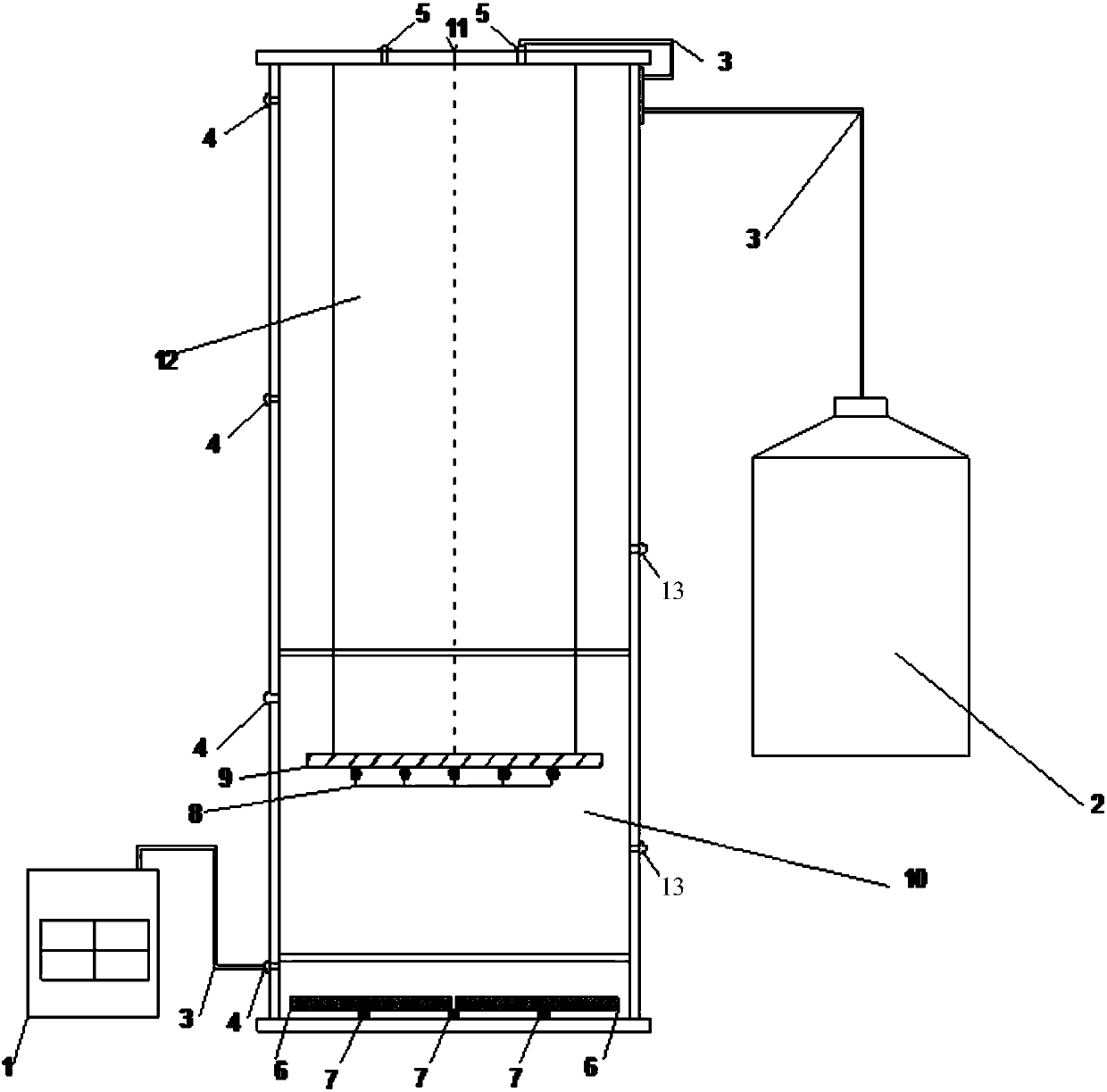

[0062] An evaluation device for the degradation effect of photocatalytic materials on harmful gases in the atmosphere, such as figure 1 As shown, it includes a gas reaction chamber 12 , a mixed compressed gas generator 2 , and a gas analyzer 1 , and the gas reaction chamber 12 includes a specimen holder 7 . The specimen support 7 is arranged at the bottom of the gas reaction chamber 12 for supporting the specimen 6 .

[0063] In this embodiment, there are four detection holes 4 with a diameter of 20 mm at four heights of 50 mm, 500 mm, 1000 mm and 1500 mm on the centerline of one side of the gas reaction chamber 12 from the experimental specimen 6. The side opposite to the side There are two air pressure adjustment holes 13 with a diameter of 20mm at the heights of 250mm and 750mm from the center line of the experimental specimen; on the top surface of the gas reaction chamber 12, the center line is 200mm away from the two sides. The air hole 5 and the air inlet 5 are used to...

Embodiment 2

[0084] A method for evaluating the degradation effect of photocatalytic materials on PM2.5, the evaluation device used is the same as in Example 1, and the method is basically the same as in Example 1, except that when the third step is implemented, the mixed gas is by NO 2 and air, and get NO in the gas reaction chamber 12 2 The stable value of the initial gas concentration is 84.7μg / m 3 ;NO 2 The stable concentration after gas degradation is 68.4μg / m 3 , to obtain titania-based photocatalytic materials for NO 2 The degradation efficiency of P = 19.24%.

Embodiment 31

[0086] A device for evaluating the degradation effect of photocatalytic materials on harmful gases in the atmosphere is basically the same as in Example 1. The difference is that in this example, the gas reaction chamber 12 also includes an ultraviolet lamp 8, and an ultraviolet lamp 8 is arranged above the ultraviolet lamp 8. The lampshade 9, the ultraviolet lampshade 9 is used to fix the ultraviolet lamp 8, the ultraviolet lampshade 9 is made of colorless transparent organic glass, the ultraviolet lampshade 9 is connected with the top of the gas reaction chamber 12 through the lampshade connecting rod, and the lampshade connecting rod can be stretched up and down , thereby driving the ultraviolet lampshade 9 and the ultraviolet lamp 8 to move up and down, thereby adjusting the distance between the ultraviolet lamp 8 and the test piece 6, for simulating different light intensities, during which, the ultraviolet intensity in the air is detected with a light intensity meter.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com