Tea extracting solution and preparation method thereof

A technology of tea extract and tea leaves, which is applied in tea extraction, tea, food science, etc., can solve the problems of unreported bitterness and astringency, few applications, etc., and achieve the effects of non-toxic activity, high catalytic efficiency, and adjustable activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] An embodiment of the tea extract of the present invention and its preparation method, the preparation method of the tea extract described in this embodiment comprises the following steps:

[0050] (1) Take Fenghuang Dancong tea and pulverize it to obtain pulverized tea leaves;

[0051] (2) Water-bath extraction: add water to the pulverized tea leaves obtained in step (1), the mass ratio of tea leaves to water is 1:10, and extract in a water bath at a temperature of 80°C for 15 minutes to obtain a water extract;

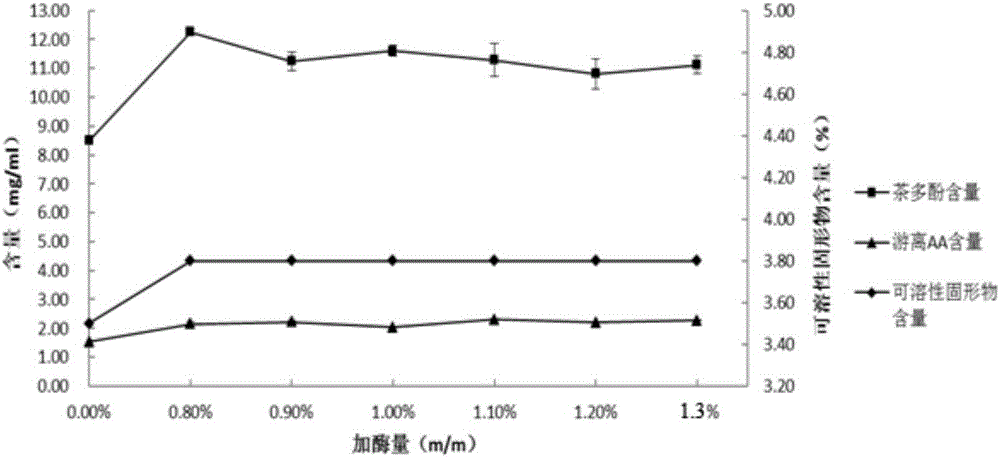

[0052] (3) Enzymolysis: cooling the water extract obtained in step (2), then adding tannase to the water extract, enzymolysis for 1 hour, then adding ProteAX protease and cellulase, and continuing enzymolysis for 2 hours, The enzymolysis temperature is 40°C; wherein, the mass percentage of ProteAX protease and tea leaves is 1.1%, the mass percentage of cellulase and tea leaves is 1.5%, and the mass percentage of tannase and tea leaves is 1.5%;

[0053] (4) Enz...

Embodiment 2

[0055] An embodiment of the tea extract of the present invention and its preparation method, the preparation method of the tea extract described in this embodiment comprises the following steps:

[0056] (1) Take Fenghuang Dancong tea and pulverize it to obtain pulverized tea leaves;

[0057] (2) Water-bath extraction: add water to the pulverized tea leaves obtained in step (1), the mass ratio of tea leaves to water is 1:10, and extract in a water bath at a temperature of 95° C. for 10 minutes to obtain a water extract;

[0058] (3) Enzymolysis: cooling the water extract obtained in step (2), then adding tannase, ProteAX protease and cellulase to the water extract, enzymolysis for 1 hour, and the enzymolysis temperature is 50°C; wherein , the mass percentage of ProteAX protease and tea leaves is 1.3%, the mass percentage of cellulase and tea leaves is 1.7%, and the mass percentage of tannase and tea leaves is 1.7%;

[0059] (4) Enzyme inactivation: the enzymolysis product obt...

Embodiment 3

[0061] An embodiment of the tea extract of the present invention and its preparation method, the preparation method of the tea extract described in this embodiment comprises the following steps:

[0062] (1) Take Fenghuang Dancong tea and pulverize it to obtain pulverized tea leaves;

[0063] (2) Water-bath leaching: add water to the pulverized tea leaves obtained in step (1), the mass ratio of tea leaves to water is 1:10, and leaching in a water bath at a temperature of 70°C for 30 minutes to obtain a water-extract;

[0064] (3) Enzymolysis: cooling the water extract obtained in step (2), then adding tannase to the water extract, enzymolysis for 4 hours, then adding ProteAX protease and cellulase, and continuing enzymolysis for 2 hours, The enzymolysis temperature is 30°C; wherein, the mass percentage of ProteAX protease and tea leaves is 1.2%, the mass percentage of cellulase and tea leaves is 1.6%, and the mass percentage of tannase and tea leaves is 1.6%;

[0065] (4) Enz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com