Mesoporous silicon dioxide-loaded metal phthalocyanine catalyst and preparation method thereof

A mesoporous silica and metal-loaded technology, which is applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc. Few types of phthalocyanines, fixed pore structure, etc., to achieve the effect of highlighting the effect of biological multiplication modification, rich types of metal ions, and mild catalytic reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

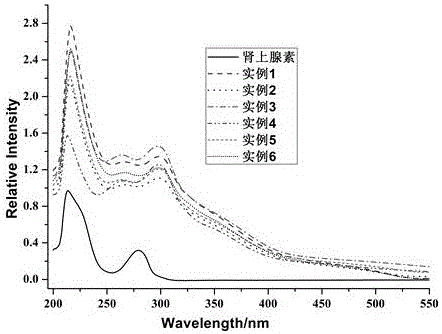

Image

Examples

Embodiment l

[0019] 1) Dissolve 10 g of tetraethyl orthosilicate and 0.5 g of Tween-80 in 5 mL of ethanol to form a solution, and then slowly add it to 30 mL of a solution containing 10 g of copper disulfonic acid phthalocyanine and 0.5 g of Tween-80 Stir in deionized water for 2 hours at room temperature, then transfer the mixture to an autoclave, crystallize at 120°C for 72 hours, cool to room temperature, filter, wash with deionized water for 3 times, and dry the solid in a vacuum dryer at 60°C After 12 hours, it was calcined in a muffle furnace at 550° C. for 3 hours to obtain copper (II) ion-modified mesoporous silica microspheres.

[0020] 2) After mixing 20 g copper(II) ion-modified mesoporous silica microspheres with 0.001 g ammonium molybdate, 1 g phthalic anhydride, 1 g ammonium chloride, and 3 g urea, place In a reaction kettle containing 70 mL of xylene, reflux reaction at 130°C for 2 hours under slow stirring conditions, after cooling to room temperature, suction filtration, w...

Embodiment 2

[0022] 1) Dissolve 10 g of tetraethyl orthosilicate and 0.5 g of Tween-80 in 5 mL of ethanol to form a solution, and then slowly add it to 30 mL of a solution containing 10 g of cobalt disulfonic acid phthalocyanine and 0.5 g of Tween-80 Stir in deionized water for 2 hours at room temperature, then transfer the mixture to an autoclave, crystallize at 120°C for 72 hours, cool to room temperature, filter, wash with deionized water for 3 times, and dry the solid in a vacuum dryer at 60°C After 12 hours, it was calcined in a muffle furnace at 550° C. for 3 hours to obtain cobalt (II) ion-modified mesoporous silica microspheres.

[0023] 2) Mix 20 g of cobalt(II) ion-modified mesoporous silica microspheres with 0.001 g of ammonium molybdate, 1 g of phthalic anhydride, 1 g of ammonium chloride, and 3 g of urea, and place In a reaction kettle containing 70 mL of xylene, reflux reaction at 130°C for 2 hours under slow stirring conditions, after cooling to room temperature, suction fil...

Embodiment 3

[0025] 1) Dissolve 10 g of tetraethyl orthosilicate and 0.5 g of Tween-80 in 5 mL of ethanol to form a solution, and then slowly add it to 30 mL of detoxification solution containing 18 g of copper tetrasulfonate phthalocyanine and 1.0 g of Tween-80 Stir in deionized water for 2 hours at room temperature, then transfer the mixture to an autoclave, crystallize at 120°C for 72 hours, cool to room temperature, filter, wash with deionized water for 3 times, and dry the solid in a vacuum dryer at 60°C After 12 hours, it was calcined in a muffle furnace at 550° C. for 3 hours to obtain copper (II) ion-modified mesoporous silica microspheres.

[0026] 2) Mix 20 g copper(II) ion-modified mesoporous silica microspheres with 0.08 g ammonium molybdate, 1.5 g phthalic anhydride, 1.5 g ammonium chloride, and 5 g urea, and place In a reaction kettle filled with 70 mL of xylene, reflux at 130°C for 2 hours under slow stirring, cool to room temperature, filter with suction, wash with deionize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com