Fatty powder for sows in lactation period and preparing method of fatty powder

A technology of fat powder and lactation, which is applied in the direction of bacteria, lactobacillus, food science, etc. used in food preparation, can solve the problems of not considering the influence of piglets, the preparation of needs, etc., to achieve improved emulsification effect, reasonable formula, and fat regulation metabolic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

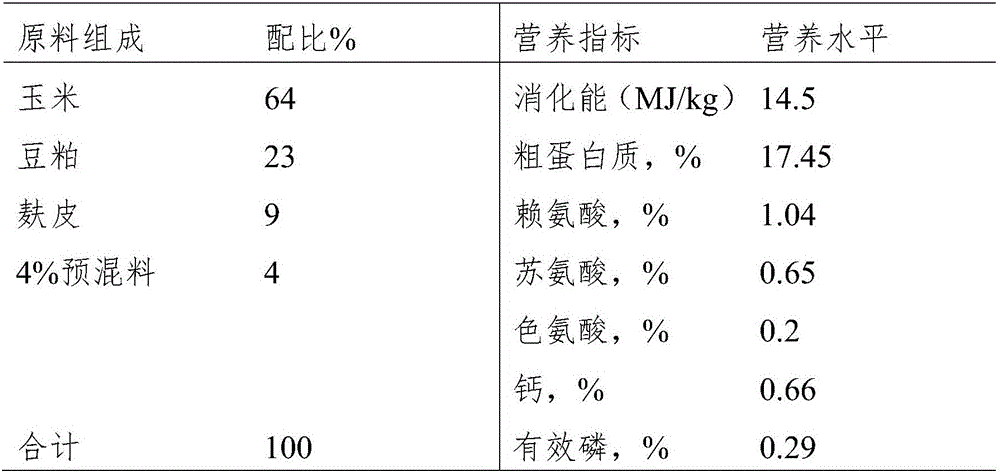

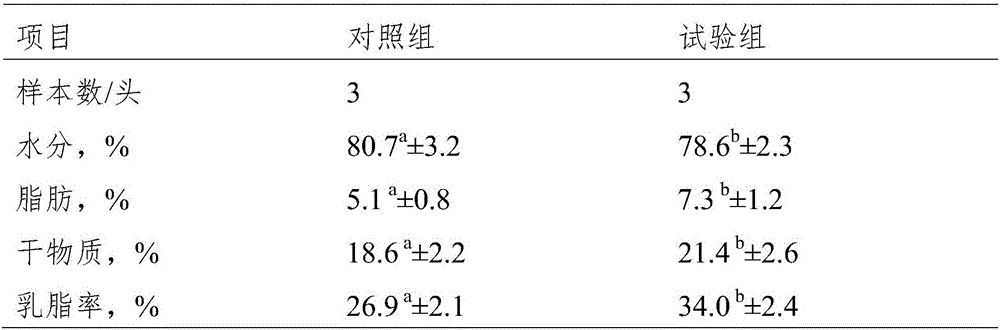

[0032] Production of fat powder products for lactating sows with a crude fat content of 50%

[0033] A kind of lactating sow fat powder is according to the following weight percentages:

[0034] 25 parts of palm kernel oil, 10 parts of deep-sea fish oil, 10 parts of soybean oil, 5 parts of compound emulsifier, 1 part of bifidoquate live bacteria microecological preparation, 47 parts of carrier, 2 parts of dispersant;

[0035] The compound emulsifier includes 2 parts of modified soybean lecithin oil, 2 parts of monoglyceride and 1 part of sodium alginate;

[0036] The carrier includes 30 parts of puffed corn flour and 17 parts of alfalfa powder;

[0037] Fluids include silica.

[0038] The preparation method of above-mentioned fat powder is as follows:

[0039] (1) Prepare raw materials;

[0040] (2) Mixed emulsification: Put 250kg of palm kernel oil, 100kg of deep-sea fish oil, 100kg of soybean oil, and 50kg of compound emulsifier into the emulsification tank according to ...

Embodiment 2

[0045] Production of fat powder products for lactating sows with a crude fat content of 55%

[0046] A kind of lactating sow fat powder is according to the following weight percentages:

[0047] 27.5 parts of palm kernel oil, 11 parts of deep-sea fish oil, 11 parts of soybean oil, 5.5 parts of compound emulsifier, 1 part of bifidoquate live bacteria microecological preparation, 42 parts of carrier, 2 parts of fluid dispersion agent;

[0048] The compound emulsifier includes 2.2 parts of modified soybean lecithin oil, 2.3 parts of mono- and diglycerides, and 1 part of sodium alginate;

[0049] Carriers include 28 parts of puffed corn flour and 14 parts of alfalfa powder;

[0050] Fluids include silica.

[0051] The preparation method of above-mentioned fat powder is as follows:

[0052] (1) Prepare raw materials;

[0053] (2) Mixed emulsification: Put 275kg of palm kernel oil, 110kg of deep-sea fish oil, 110kg of soybean oil, and 55kg of compound emulsifier into the emulsif...

Embodiment 3

[0058] Production of fat powder products for lactating sows with a crude fat content of 60%

[0059] A kind of lactating sow fat powder is according to the following weight percentages:

[0060] 30 parts of palm kernel oil, 12 parts of deep-sea fish oil, 12 parts of soybean oil, 6 parts of compound emulsifier, 1 part of bifidoquate live bacteria microecological preparation, 37 parts of carrier, 2 parts of dispersant;

[0061] The compound emulsifier includes 2.5 parts of modified soybean lecithin oil, 2.5 parts of mono- and diglycerides, and 1 part of sodium alginate;

[0062] The carrier includes 28 parts of puffed corn flour and 9 parts of alfalfa powder;

[0063] Fluids include silica.

[0064] The preparation method of above-mentioned fat powder is as follows:

[0065] (1) Prepare raw materials;

[0066] (2) Mixed emulsification: put 300kg of palm kernel oil, 120kg of deep-sea fish oil, 120kg of soybean oil, and 60kg of compound emulsifier into the emulsification tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com