Sweet potato powder capable of maintaining beauty and slimming body and making method thereof

A sweet potato powder, slimming technology, applied in the function of food ingredients, food forming, food science and other directions, can solve problems such as obesity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

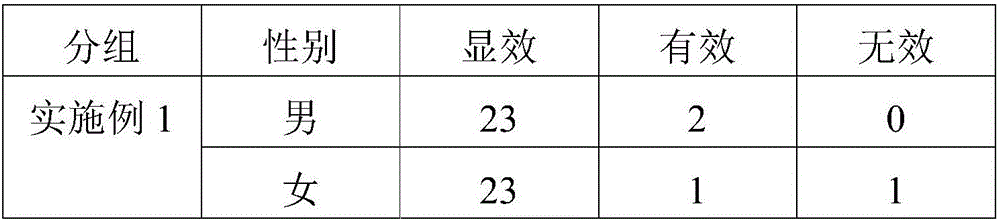

Embodiment 1

[0031] The specific preparation method of sweet potato flour for beauty and slimming comprises the following steps:

[0032] (1) Select fresh sweet potatoes (Yushu 17, place of origin: Pengshui County, Chongqing City) with a smooth surface, no soil clods, no moths, no disease spots, and no waterlogging or freezing damage, clean them, peel them, and cut them into sizes 8mm pieces, to obtain sweet potato strips, and then soak the sweet potato strips in the color protection solution for color protection for 25 minutes. color product;

[0033] (2) Add the color-protecting product to an enzyme solution at a temperature of 35°C for enzymolysis for 2.5 hours, the mass ratio of the color-protecting product to the enzyme solution is 1:5, and then filter with a 180-mesh filter cloth to obtain an enzymatic hydrolyzate;

[0034] (3) Dry the enzymatic hydrolyzate at 65°C for 12 hours to obtain the dried material, and add the dried material to a pulverizer (the model is HAO-2200 grain mill...

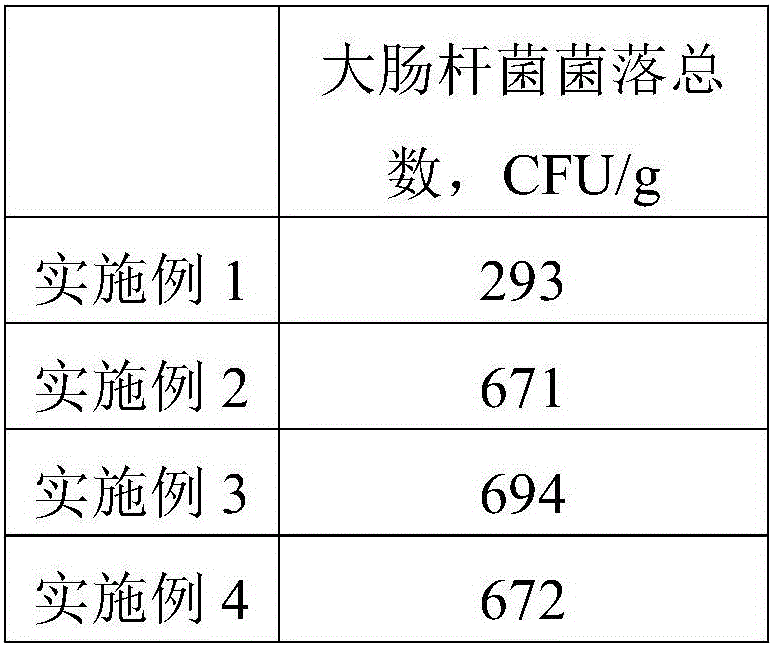

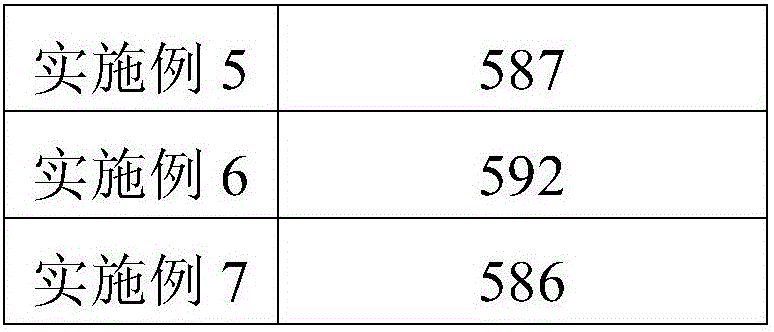

Embodiment 2

[0040] It is basically the same as in Example 1, except that the enzyme is obtained by stirring and mixing pullulanase and glucoamylase at a mass ratio of 1:1. Obtain the beautifying and slimming sweet potato powder of embodiment 2.

Embodiment 3

[0042] It is basically the same as Example 1, except that the enzyme is obtained by stirring and mixing α-amylase and glucoamylase at a mass ratio of 1:1. Obtain the beautifying and slimming sweet potato powder of embodiment 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com