Preparation method of resin carbon for blood purification

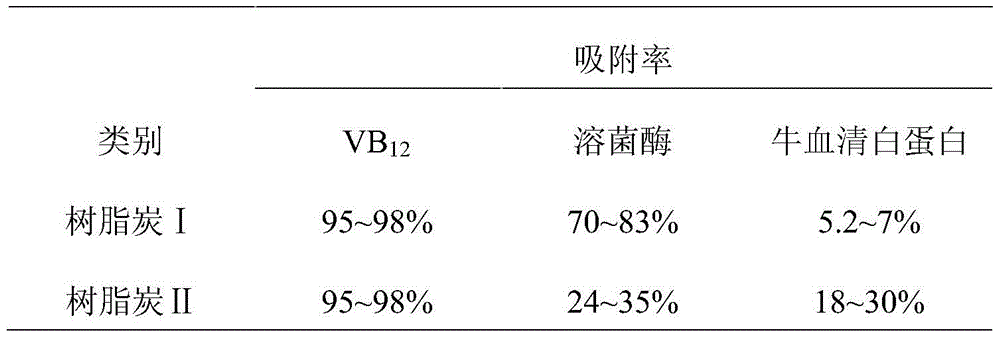

A technology of blood purification and resin carbon, which is applied in the direction of chemical instruments and methods, inorganic chemistry, carbon compounds, etc., can solve the problems of less direct application alone, reduced adsorption effect of middle molecular substances, and ineffective removal of toxic substances in uremia patients. , to achieve excellent adsorption effect, less pollution and high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A kind of preparation method of the resin charcoal that is used for blood purification, carries out according to the following steps:

[0035] Step 1. Mix p-chloromethylstyrene monomer and divinylbenzene according to the mass ratio of 1:1 to prepare an oil phase mixture, and add 0.5% wt of benzoyl peroxide to the oil phase mixture at the same time, the oil A porogen with a mass of 2%wt of the phase mixture and a stabilizer with a mass of 3%wt of the oil phase mixture; crosslinked chloromethylated styrene-divinylbenzene microspheres are prepared by a suspension polymerization method;

[0036] The porogen is any one or two of toluene, naphthalene, paraffin oil, octane, hexadecane, and the stabilizer is polyvinyl alcohol;

[0037] Step 2. Wash the chloromethylated styrene-divinylbenzene microspheres with water and put them into a swelling agent for swelling. The swelling agent is pyridine, and the swelling time is 2 hours, and then add the chloromethylated styrene - Divin...

Embodiment 2

[0043] A kind of preparation method of the resin charcoal that is used for blood purification, carries out according to the following steps:

[0044] Step 1. Mix p-chloromethylstyrene monomer and divinylbenzene according to the mass ratio of 1:2 to prepare an oil phase mixture, and add 1% wt of benzoyl peroxide to the oil phase mixture at the same time, the oil A porogen with a mass of 25%wt of the phase mixture and a stabilizer with a mass of 10%wt of the oil phase mixture; crosslinked chloromethylated styrene-divinylbenzene microspheres are prepared by a suspension polymerization method;

[0045] The porogen is any three or any four of toluene, naphthalene, paraffin oil, octane, hexadecane, and the stabilizer is polyvinyl alcohol;

[0046] Step 2, wash the chloromethylated styrene-divinylbenzene microspheres with acetone and put them into a swelling agent for swelling, the swelling agent is dimethyl sulfoxide, and the swelling time is 4h, then add the chlorine Methylate fer...

Embodiment 3

[0052] A kind of preparation method of the resin charcoal that is used for blood purification, carries out according to the following steps:

[0053] Step 1. Mix p-chloromethylstyrene monomer and divinylbenzene according to the mass ratio of 1:1.5 to prepare an oil phase mixture, and add 0.8% wt of benzoyl peroxide to the oil phase mixture at the same time, the oil A porogen with a mass of 40%wt of the phase mixture and a stabilizer with a mass of 7%wt of the oil phase mixture; crosslinked chloromethylated styrene-divinylbenzene microspheres were prepared by suspension polymerization;

[0054] The porogen is obtained by mixing toluene, naphthalene, paraffin oil, octane and hexadecane in a mass ratio of 2:3:1.5:0.8:0.5, and the stabilizer is polyvinyl alcohol;

[0055] Step 2. Wash the chloromethylated styrene-divinylbenzene microspheres with water or acetone and then put them into a swelling agent for swelling. The swelling agent is N,N-dimethylformamide, and the swelling time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com