Health care non-transgenic sweet potato powder and preparation method thereof

A non-transgenic, sweet potato flour technology, applied in the field of health-care non-transgenic sweet potato flour and its preparation, can solve problems such as obesity, achieve the effects of no foreign matter addition, protection of biologically active ingredients, and favorable absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

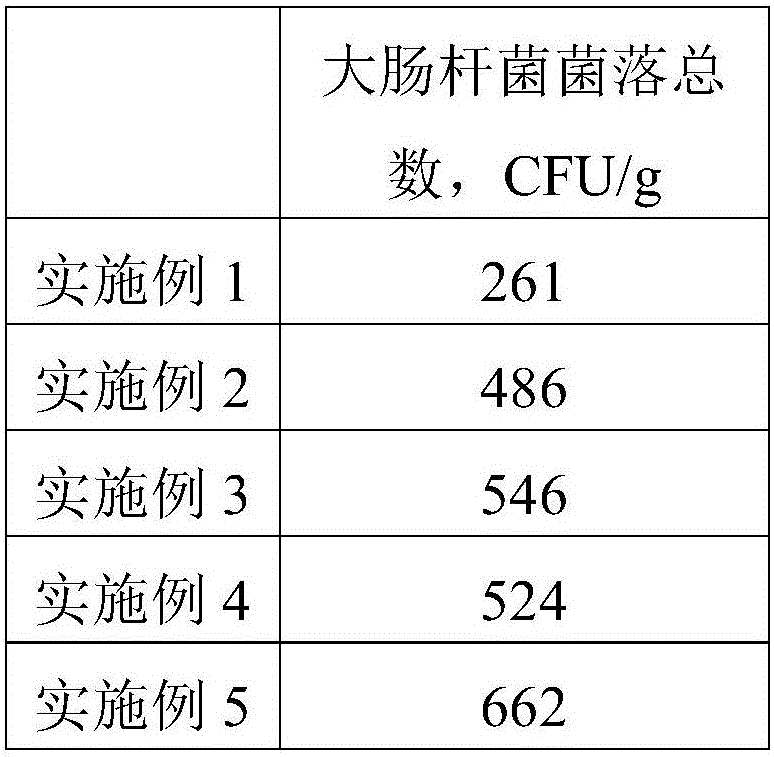

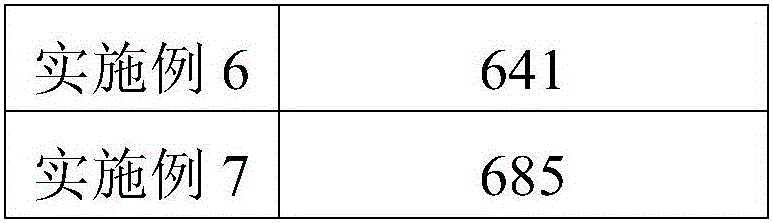

Examples

Embodiment 1

[0030] The concrete preparation method of health-care non-transgenic sweet potato powder comprises the following steps:

[0031] (1) Wash the sweet potato (Yushu 17, place of origin: Pengshui County, Chongqing City) with clean water, drain, crush to 10 mesh, and then freeze-dry at -30°C for 10 hours to obtain dry powder;

[0032] (2) Add the dry powder to a superfine pulverizer (SQW-6A superfine pulverizer provided by Shandong Sanqing Stainless Steel Equipment Co., Ltd.) for superfine pulverization to 5 μm to obtain a superfine powder;

[0033] (3) adding the superfine powder into the enzyme solution with a temperature of 45° C. and stirring at a speed of 400 rpm for 4.5 hours, and then performing centrifugation in a centrifuge with a speed of 3800 rpm for 10 minutes to obtain a broken wall powder;

[0034] (4) Vacuum-dry the broken-wall powder at 60°C for 10 hours, then sterilize it by ultraviolet irradiation, and the irradiation dose is 350J / m 2 , and the irradiation time w...

Embodiment 2

[0040] It is basically the same as in Example 1, except that the compound enzyme is obtained by stirring and mixing evenly with glucoamylase and β-glucosidase at a mass ratio of 1:1. Obtain the health-care non-transgenic sweet potato powder of embodiment 2.

Embodiment 3

[0042] It is basically the same as Example 1, except that the compound enzyme is obtained by stirring and mixing uniformly with β-amylase and β-glucosidase at a mass ratio of 1:1. Obtain the health-care non-transgenic sweet potato powder of embodiment 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com