Artificial iris capable of fixing artificial lens as well as material and processing method of artificial iris

An intraocular lens and iris technology, applied to eye implants and other directions, can solve the problems of cataracts, lens capsular bag lesions, difficult surgical operations, etc., and achieves the operation of avoiding suture fixation, convenient fixation, and simple and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

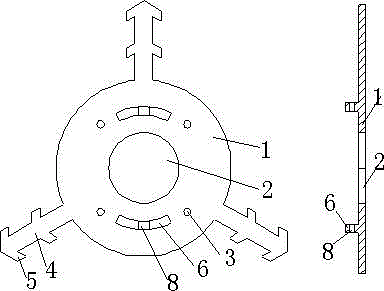

Embodiment 1

[0060] Proportion: Silicone color masterbatch composition 35% iron black and 65% silica gel, weigh the silicone MED6820 (A, B) component ratio according to 1:1, then add the color masterbatch dosage 0.5% silica gel color masterbatch, mix evenly, Debubble under -0.1MPa vacuum for 10 minutes, then inject the mixed silica gel into the mold through a pressurizer, put the mold in an oven at 140°C, and take it out after 30 minutes. The processed artificial iris septum 1 has a diameter of 12 mm, a thickness of 0.5 mm, a diameter of the central hole 2 of 4 mm, and three loops 4 .

[0061] After testing, the light transmittance at the wavelength of 300-1100nm is ≤0.03%. The Shore hardness (Shore A) is 45, the elongation is 82.2%, the tear strength of loop 4 is 0.55N / mm, and the tensile strength of the artificial iris septum is 650KPa.

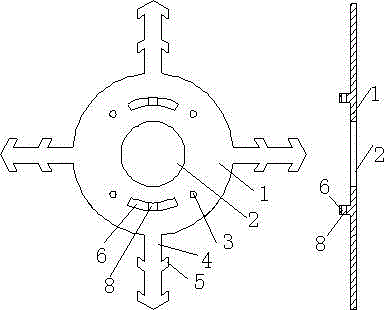

Embodiment 2

[0063] Proportion: 20% carbon black and 80% silica gel for silica gel color masterbatch: Weigh the components of silica gel MED6820 (A, B) according to 1:1, then add 2.0% silica gel masterbatch, mix well, Debubble under -0.1MPa vacuum for 10 minutes, then inject the mixed silica gel into the mold through a pressurizer, put the mold in an oven at 140°C, and take it out after 40 minutes. The processed artificial iris septum 1 has a diameter of 11 mm, a thickness of 0.40 mm, a diameter of the central hole 2 of 3.5 mm, and three loops 4 .

[0064] After testing, the light transmittance at the wavelength of 300-1100nm is ≤0.03%, the Shore hardness (Shore A) is 40, the elongation is 91.5%, the tear resistance of loop 4 is 0.51N / mm, and the tensile strength of the artificial iris septum is The strength is 632KPa.

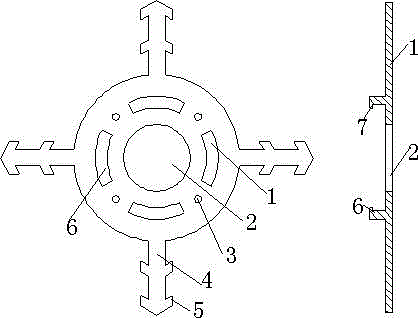

Embodiment 3

[0066] Proportion: Silicone color masterbatch composition 35% iron black and 65% silica gel, weigh the silicone MED6820 (A, B) component ratio according to 1:1, then add the color masterbatch dosage of 1.0% silica gel color masterbatch, mix well, Debubble under -0.1MPa vacuum for 10 minutes, then inject the mixed silica gel into the mold through a pressurizer, put the mold in an oven at 150°C, and take it out after 30 minutes. The processed artificial iris septum 1 has a diameter of 12 mm, a thickness of 0.40 mm, a diameter of the central hole 2 of 4.5 mm, and three loops 4 .

[0067] After testing, the light transmittance at the wavelength of 300-1100nm is ≤0.03%. The Shore hardness (Shore A) is 37, the elongation is 94.3%, the tear strength of the loop 4 is 0.45N / mm, and the tensile strength of the artificial iris septum is 620KPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com