Toothpaste

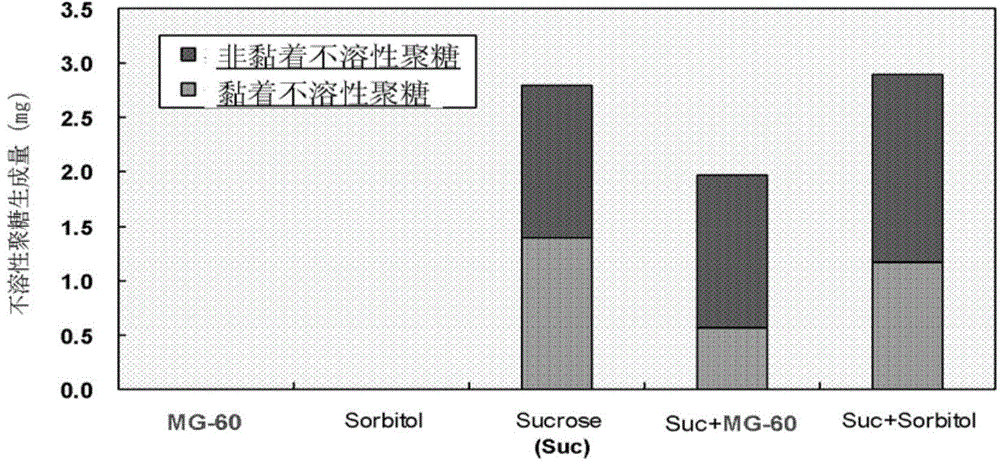

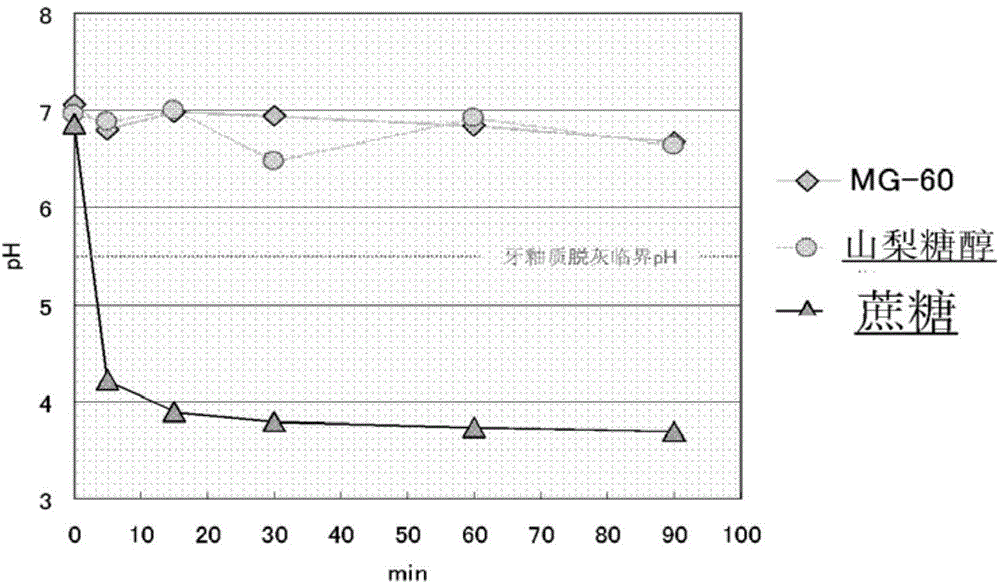

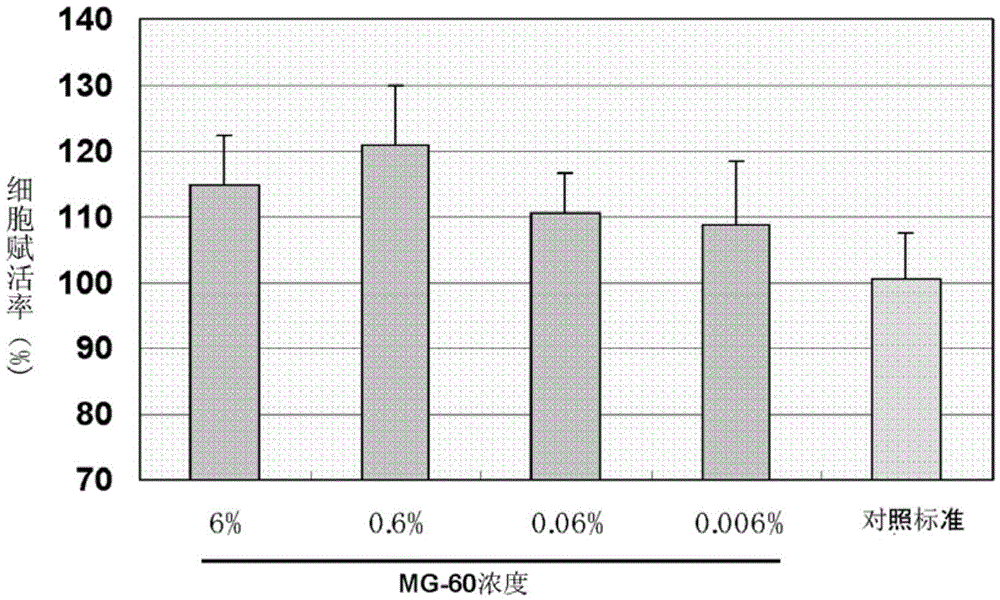

A technology of toothpaste and xylitol, which is applied in dentistry, medical science, oral care, etc., can solve the problems of low degree of calcification on the surface of teeth, increased prevalence of dental fluorosis, and easy damage, so as to achieve better health protection, The effect of reducing the prevalence of dental caries and avoiding dental fluorosis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] Calculated according to the production of 100Kg toothpaste, the formula is as follows

[0075] Glycerin 10.000Kg

[0076] Cellulose gum 0.350Kg

[0077] Xanthan gum 0.500Kg

[0078] Hydroxyethyl cellulose 0.350Kg

[0079] Sorbitol (sugar) alcohol 54.500Kg

[0080] Polyethylene glycol-2M 4.000Kg

[0081] Poloxamer 407 0.800Kg

[0082] Xylitol 0.700Kg

[0083] Stevioside 0.300Kg

[0084] Allantoin 0.050Kg

[0085] Maltooligosaccharide glucoside and hydrogenated starch hydrolyzate (Japan Hayashibara MG-60) 0.700Kg

[0086] Methylparaben 0.150Kg

[0087] Cocamidopropyl Betaine 0.010Kg

[0088] 0.1% aqueous solution of CI 16035 1Kg

[0089] 0.1% aqueous solution of CI 16255 1Kg

[0090] Hydrated silica 15Kg

[0091] Sodium Lauryl Sulfate 1.550Kg

[0092] Flavor 0.900Kg

[0093] Menthol Lactate 0.100Kg

[0094] Water 8.000Kg

[0095] Preparation:

[0096] According to the above recipe

[0097] A Disperse glycerin, cellulose gum, xanthan gum, and hydroxyethy...

Embodiment 2

[0102] Calculated according to the production of 100Kg toothpaste, the formula is as follows

[0103] Glycerin 11.000Kg

[0104] Cellulose gum 0.350Kg

[0105] Xanthan gum 0.500Kg

[0106] Hydroxyethyl cellulose 0.350Kg

[0107] Sorbitol (sugar) alcohol 55.000Kg

[0108] Polyethylene glycol-2M 4.000Kg

[0109] Poloxamer 407 0.800Kg

[0110] Xylitol 0.800Kg

[0111] Stevioside 0.300Kg

[0112] Allantoin 0.050Kg

[0113] Maltooligosaccharide glucoside and hydrogenated starch hydrolyzate (Japanese Hayashibara MG-60) 0.900Kg

[0114] Methylparaben 0.150Kg

[0115] Cocamidopropyl Betaine 0.010Kg

[0116] 0.1% aqueous solution of CI 16035 1Kg

[0117] 0.1% aqueous solution of CI 16255 1Kg

[0118] Hydrated silica 15.5Kg

[0119] Sodium Lauryl Sulfate 1.600Kg

[0120] Flavor 0.900Kg

[0121] Menthol Lactate 0.100Kg

[0122] Water 5.710Kg

[0123] Preparation:

[0124] According to the above recipe

[0125] A Disperse glycerin, cellulose gum, xanthan gum, and hydroxye...

Embodiment 3

[0130] Calculated according to the production of 100Kg toothpaste, the formula is as follows

[0131] Glycerin 9.000Kg

[0132] Cellulose gum 0.4Kg

[0133] Xanthan gum 0.400Kg

[0134] Hydroxyethyl Cellulose 0.4Kg

[0135] Sorbitol (sugar) alcohol 55.000Kg

[0136] Polyethylene glycol-2M 4.000Kg

[0137] Poloxamer 407 0.800Kg

[0138] Xylitol 0.900Kg

[0139] Stevioside 0.300Kg

[0140] Allantoin 0.050Kg

[0141] Maltooligosaccharide glucoside and hydrogenated starch hydrolyzate (Japan Hayashibara MG-60) 0.800Kg

[0142] Methylparaben 0.150Kg

[0143] Cocamidopropyl Betaine 0.010Kg

[0144] 0.1% aqueous solution of CI 16035 1Kg

[0145] 0.1% aqueous solution of CI 16255 1Kg

[0146] Hydrated silica 15.4Kg

[0147] Sodium Lauryl Sulfate 1.600Kg

[0148] Flavor 0.900Kg

[0149] Menthol Lactate 0.100Kg

[0150] Water 7.79Kg

[0151] Preparation:

[0152] According to the above recipe

[0153] A Disperse glycerin, cellulose gum, xanthan gum, and hydroxyethyl ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com