Mercaptamine premix and preparation method thereof

A technology of cysteamine hydrochloride and premix, which is applied in the direction of anti-toxic agents, pharmaceutical formulas, medical preparations of non-active ingredients, etc., and can solve the problem of affecting the use effect of products, affecting the gastrointestinal function of animals, easy oxidation and moisture absorption, etc. Problems, achieve the effect of reducing the probability of moisture absorption, oxidation, moisture absorption, and irritation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

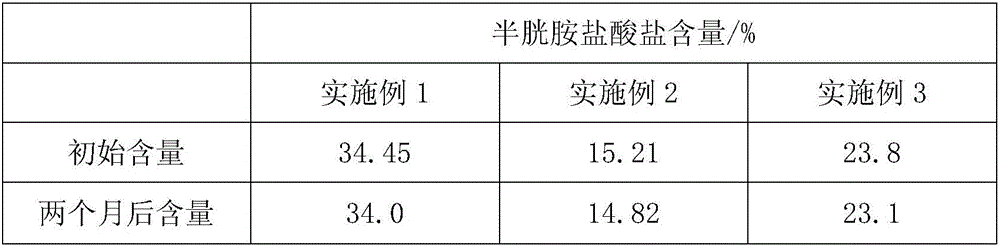

Embodiment 1

[0023] (1) 12g chitosan and 5g sodium hydroxymethyl cellulose are added to 100g 3wt% aqueous acetic acid solution, after mixing uniformly, 35g cysteamine hydrochloride is added thereto, and 50.8g cysteamine salt is obtained through spray drying Salt slow-release granules.

[0024] (2) After mixing 50g of cysteamine hydrochloride slow-release granules, 5g of hygroscopic agent, 12g of polyethylene glycol, 3g of cyclamate, 30g of montmorillonite and 30g of 30wt% ethanol aqueous solution, extruding and granulating through an extruder ;

[0025] (3) Step (2) gained wet granules are dried using 20 mesh, 80 mesh grading and sieving sieves to obtain a particle size of 20-80 mesh cysteamine hydrochloride premix, and the particle size is less than 20 mesh and greater than 80 mesh particles Go back to step (2) to re-granulate.

Embodiment 2

[0027] (1) 10g chitosan and 6g sodium hydroxymethyl cellulose are added to 100g 3wt% aqueous acetic acid solution, after mixing uniformly, 46.4g cysteamine hydrochloride is added thereto, and 61g cysteamine salt is obtained through spray drying Salt slow-release granules.

[0028] (2) After mixing 20g of cysteamine hydrochloride slow-release granules, 3g of hygroscopic agent, 15g of polyethylene glycol, 2g of cyclamate, 60g of montmorillonite and 35g of 30wt% ethanol aqueous solution, extruding and granulating through an extruder ;

[0029] (3) Step (2) gained wet granules are dried using 20 mesh, 80 mesh grading and sieving sieves to obtain a particle size of 20-80 mesh cysteamine hydrochloride premix, and the particle size is less than 20 mesh and greater than 80 mesh particles Go back to step (2) to re-granulate.

Embodiment 3

[0031] (1) 15g chitosan and 4g sodium hydroxymethyl cellulose are added to 100g 3wt% aqueous acetic acid solution, after mixing uniformly, 23.8g cysteamine hydrochloride is added thereto, and 40g cysteamine salt is obtained through spray drying Salt slow-release granules.

[0032] (2) After mixing 40g cysteamine hydrochloride slow-release granules, 4g hygroscopic agent, 8g polyethylene glycol, 1g cyclamate, 47g montmorillonite and 40g 30wt% ethanol aqueous solution, extrude and granulate through an extruder ;

[0033] (3) Step (2) gained wet granules are dried using 20 mesh, 80 mesh grading and sieving sieves to obtain a particle size of 20-80 mesh cysteamine hydrochloride premix, and the particle size is less than 20 mesh and greater than 80 mesh particles Go back to step (2) to re-granulate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com