Two-aqueous-phase membrane extraction method and device

A two-phase, extraction technology, applied in countercurrent extraction, co-current extraction, solvent extraction, etc., can solve the problems of uncertain target metal separation selectivity, difficult recovery and recycling of phase-forming substances, and high waste treatment costs. Achieve the effect of easy recycling, small footprint and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A solution containing chromium: the concentration of Cr(VI) is 5mmol / L, and the pH value of the solution is 6.

[0033] The flat membrane module is prepared by using the polytetrafluoroethylene flat membrane with ion transfer function, the module parameters are 60cm×40cm, the number of membrane modules is 10, and the total effective area of the module membrane is 2.7m 2 .

[0034] Polyethylene glycol with a molecular weight of 20,000 was used as the extractant, and a 75 g / L polyethylene glycol solution was configured as the polymer phase.

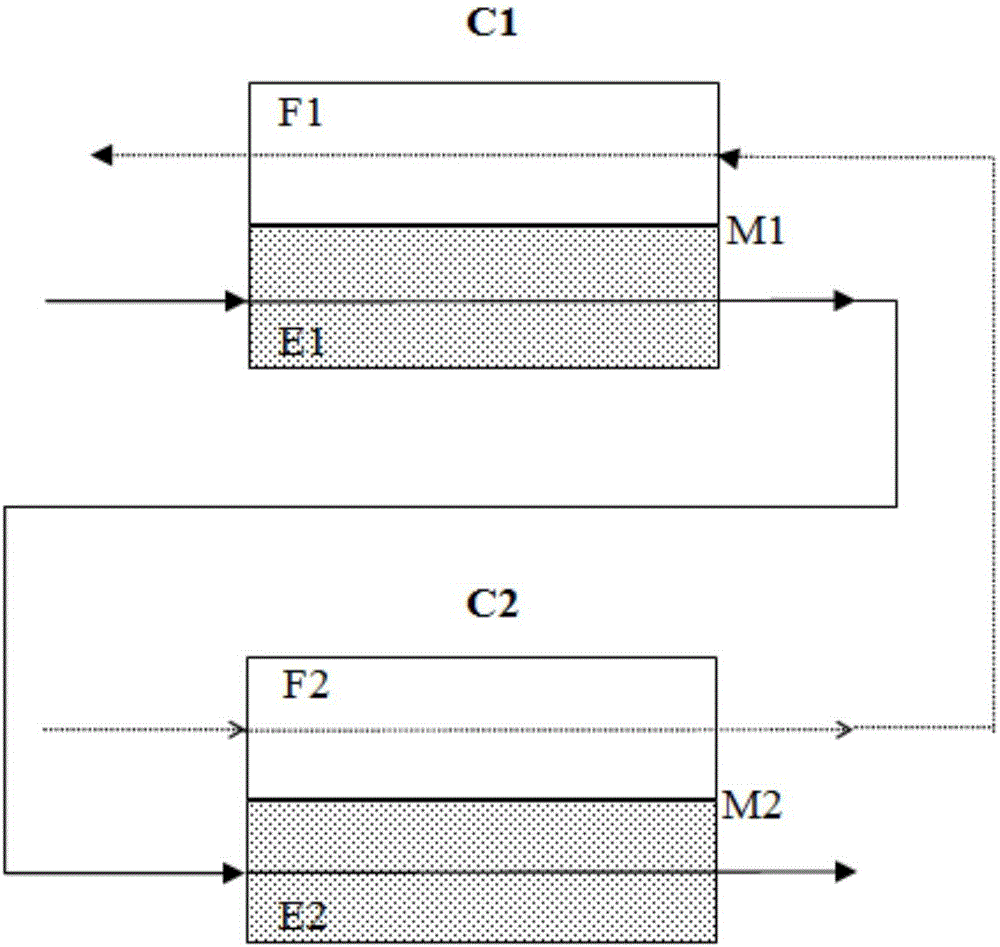

[0035] The chromium-containing feed liquid enters the membrane module, and the feed liquid phase and the polymer phase between the membrane modules flow in reverse on both sides of the membrane, that is, the polymer phase extracted through the membrane of this stage enters the membrane module of the next stage, and passes through the membrane of this stage. The liquid phase of the membrane extraction enters the previous membrane m...

Embodiment 2

[0038] A solution containing chromium: the concentration of Cr(VI) is 1mmol / L, and the pH value of the solution is 3.

[0039]A flat membrane module is prepared by using a polytetrafluoroethylene flat membrane with ion transfer function, the module parameters are 60cm×40cm, the number of membrane modules is 15, and the total effective area of the module membrane is 4m 2 .

[0040] The polyoxyethylene-polyoxypropylene copolymer with an average molecular weight of 10,000 (wherein the polyethylene oxide block accounts for 40% of the mass fraction of the copolymer) is used as the extraction agent, and a 10 g / L copolymer solution is configured as the polymer phase .

[0041] The chromium-containing feed liquid enters the membrane module, and the feed liquid phase and the polymer phase between the membrane modules flow in reverse on both sides of the membrane, that is, the polymer phase extracted through the membrane of this stage enters the membrane module of the next stage, and...

Embodiment 3

[0044] A solution containing iron: the concentration of Fe(II) is 3mmol / L, and the pH value of the solution is 3.

[0045] The polysulfone ultrafiltration membrane with ion transfer function is used to prepare a flat membrane module, the module parameters are 60cm×40cm, the number of membrane modules is 10, and the total effective area of the module membrane is 2.7m 2 .

[0046] The polysulfone ultrafiltration membrane used in this example is a self-prepared membrane. The preparation method is: dissolve 18% polysulfone in N,N-dimethylformamide solvent, let it stand for 3 days after completely dissolving, and use After defoaming in a vacuum oven for 15 minutes, use a flat film scraping machine to continuously scrape a polymer solution with a thickness of 250 μm on the non-woven fabric, and immediately immerse it in a water bath at 20°C to form a film.

[0047] The polyethylene glycol with an average molecular weight of 100,000 is used as the extraction agent, and o-phenanthr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com