Stirring type wet flue gas desulfurization device of sintering machine

A desulfurization device and stirring technology, which is applied in the field of agitating wet flue gas desulfurization devices of sintering machines, can solve the problems of insufficient oxidation of sulfite, incomplete desulfurization, low desulfurization efficiency, etc., so as to increase the effect and the desulfurization time. , saving manpower and material resources, high desulfurization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

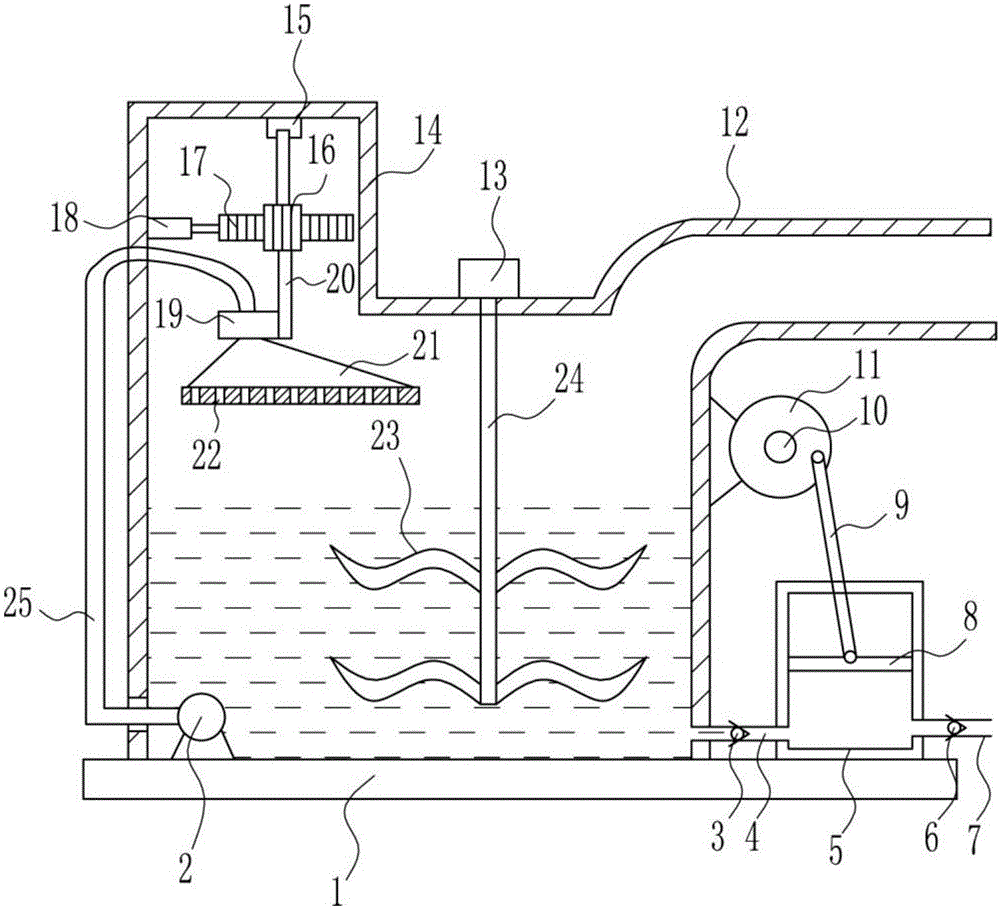

Embodiment 1

[0035] A sintering machine stirring wet exhaust gas desulfurization device, such as Figure 1-4As shown, it includes a bottom plate 1, a water pump 2, a first one-way valve 3, a hard pipe 4, a compression cylinder 5, a second one-way valve 6, an intake pipe 7, a piston 8, a connecting rod 9, a first motor 10, Disc 11, smoke exhaust pipe 12, second motor 13, processing box 14, bearing housing 15, gear 16, rack 17, electric push rod 18, fixed sleeve 19, rotating rod 20, nozzle 21, stirring blade 23, stirring Rod 24 and flexible pipe 25, base plate 1 is provided with treatment box 14 and compression cylinder 5, treatment box 14 is positioned at the left side of compression cylinder 5, is connected with hard Pipe 4, hard pipe 4 is provided with a first one-way valve 3, the lower part of the right side of the compression cylinder 5 is provided with an air intake pipe 7, the air intake pipe 7 is provided with a second one-way valve 6, and the compression cylinder 5 is provided with ...

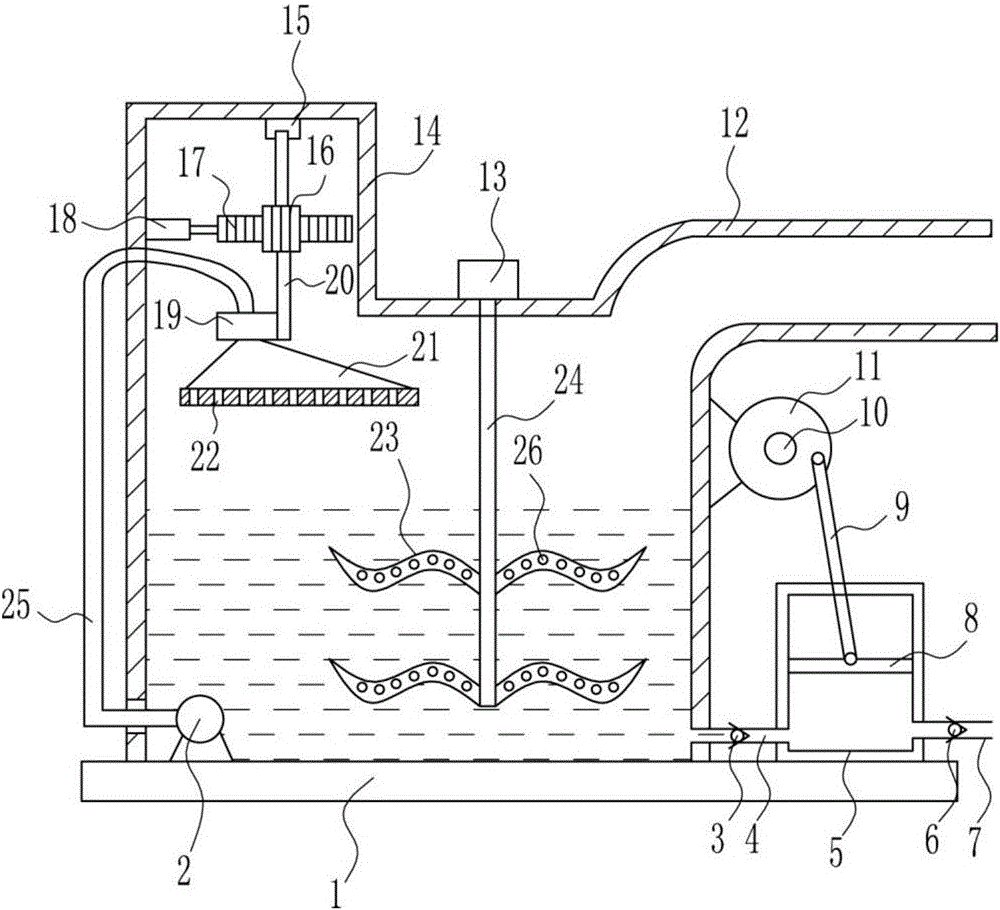

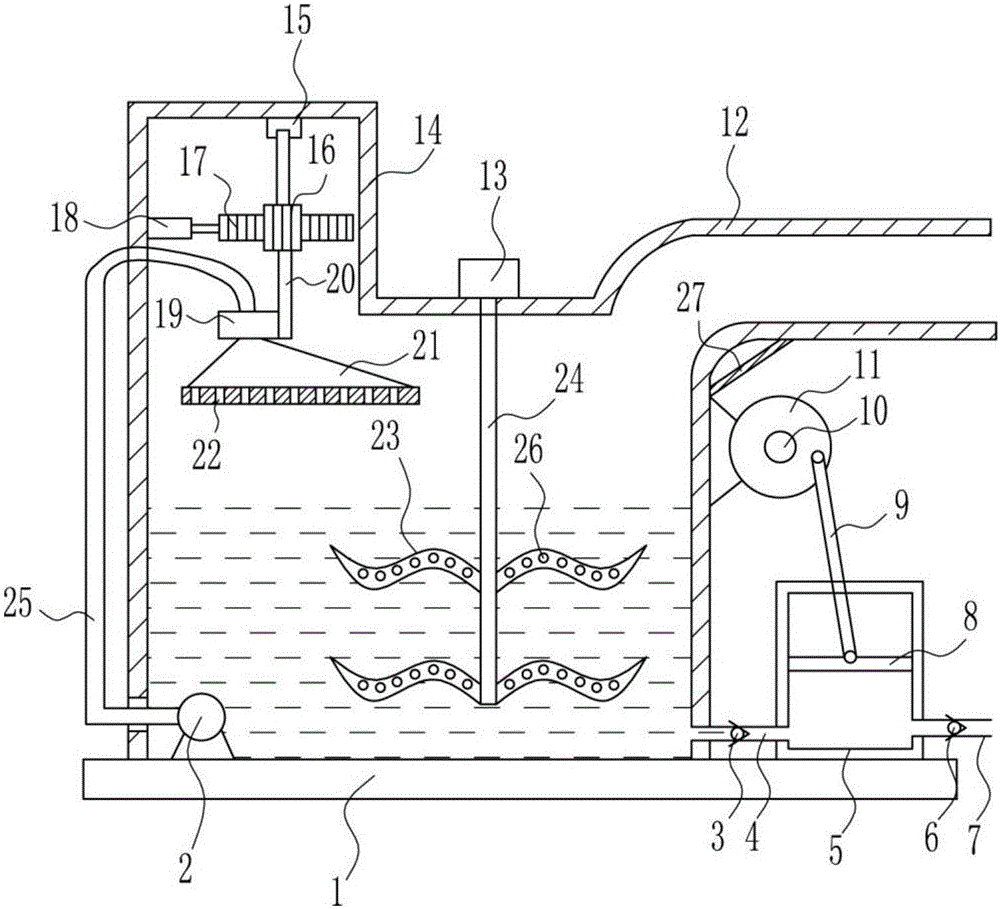

Embodiment 2

[0037] A sintering machine stirring wet exhaust gas desulfurization device, such as Figure 1-4 As shown, it includes a bottom plate 1, a water pump 2, a first one-way valve 3, a hard pipe 4, a compression cylinder 5, a second one-way valve 6, an intake pipe 7, a piston 8, a connecting rod 9, a first motor 10, Disc 11, smoke exhaust pipe 12, second motor 13, processing box 14, bearing housing 15, gear 16, rack 17, electric push rod 18, fixed sleeve 19, rotating rod 20, nozzle 21, stirring blade 23, stirring Rod 24 and flexible pipe 25, base plate 1 is provided with treatment box 14 and compression cylinder 5, treatment box 14 is positioned at the left side of compression cylinder 5, is connected with hard Pipe 4, hard pipe 4 is provided with a first one-way valve 3, the lower part of the right side of the compression cylinder 5 is provided with an air intake pipe 7, the air intake pipe 7 is provided with a second one-way valve 6, and the compression cylinder 5 is provided with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com