Preparation method of polyamide reverse osmosis membrane modified by graphene oxide subjected to acylating chlorination, modified reverse osmosis membrane and application thereof

An oxychloride, reverse osmosis membrane technology, applied in chemical instruments and methods, osmosis/dialysis water/sewage treatment, reverse osmosis, etc., can solve the problem of lack of antibacterial properties, and achieve easy operation, low energy consumption, and water quality. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

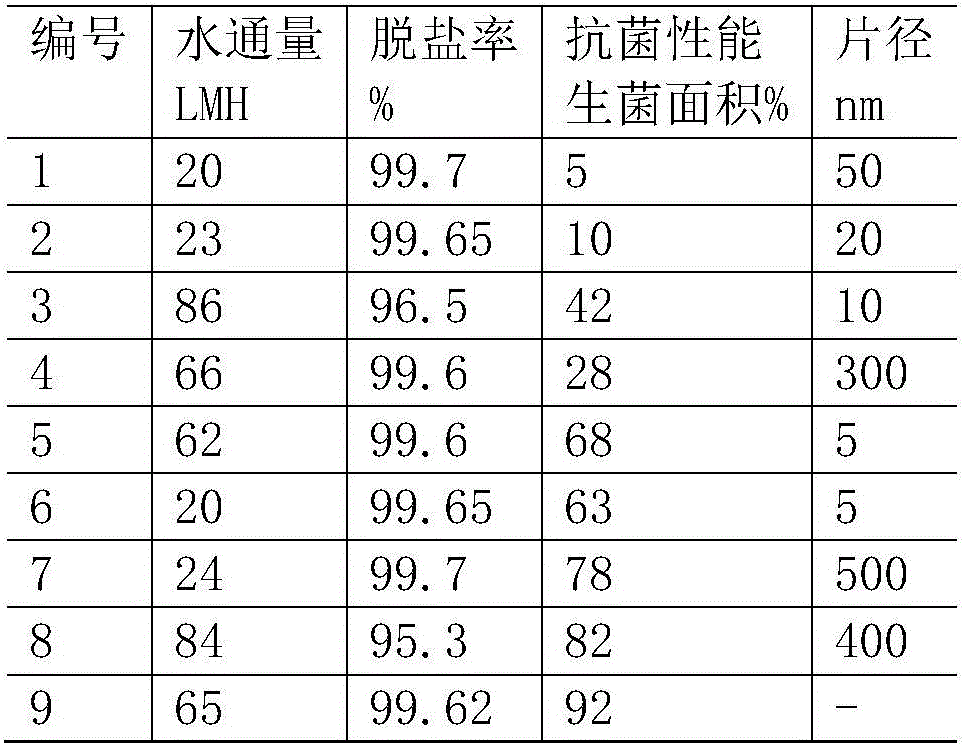

Embodiment 1

[0050] Aqueous phase solution: 10% by weight m-phenylenediamine aqueous solution

[0051] Oil phase solution: 1% by weight of trimesoyl chloride in n-hexane

[0052] Preparation of modifier: prepare 0.1g / L single-layer graphene with a sheet diameter of 50nm + 0.5g / L Isopar E solution of thionyl chloride, mix well, and remove thionyl chloride by rotary evaporation at -0.1MPa and 60°C Get modifiers.

[0053] Soak the polysulfone ultrafiltration membrane in the water phase solution for 20s, remove the excess solution after taking it out; then soak it in the oil phase solution for 20s, remove the excess solution after taking it out; then soak it in the modifier for 120s, and then bake it at 60°C Dry for 240s to obtain the polyamide reverse osmosis membrane 1 modified by acyl chloride graphene oxide.

Embodiment 2

[0055] Aqueous phase solution: 5% by weight m-phenylenediamine aqueous solution

[0056] Oil phase solution: 2% by weight isophthaloyl dichloride in cyclohexane

[0057] Preparation of modifier: prepare 0.5g / L single-layer graphene with a sheet diameter of 20nm + 0.1g / L Isopar E solution of thionyl chloride, mix well, and remove thionyl chloride by rotary evaporation at -0.5MPa, 80°C Get modifiers.

[0058] Soak the polysulfone ultrafiltration membrane in the water phase solution for 60s, remove the excess solution after taking it out; then soak it in the oil phase solution for 60s, remove the excess solution after taking it out; then soak it in the modifier for 1800s, and then bake it at 100°C Dry for 100s to obtain the polyamide reverse osmosis membrane 2 modified by acyl chloride graphene oxide.

Embodiment 3

[0060] Aqueous phase solution: 0.1% by weight p-phenylenediamine aqueous solution

[0061] Oil phase solution: n-hexane solution of 0.02% by weight phthaloyl chloride

[0062] Preparation of modifier: Prepare 5g / L single-layer graphene oxide with a sheet diameter of 10nm + 1g / L Isopar G solution of thionyl chloride, mix well and remove thionyl chloride by rotary evaporation at -0.5MPa and 80°C to obtain Modifier.

[0063] Soak the polysulfone ultrafiltration membrane in the water phase solution for 30s, remove the excess solution after taking it out; then soak it in the oil phase solution for 30s, remove the excess solution after taking it out; then soak it in the modifier for 1200s, and then bake it at 80°C Dry for 80s to obtain the polyamide reverse osmosis membrane 3 modified by acyl chloride graphene oxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com