Material guide device with inward turned arc baffle plates and arc material guide plates

A material guide device and arc-shaped baffle technology, applied in the direction of feeding devices, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of secondary pollution of the environment and the inability to realize effective and reasonable utilization of resources, and achieve the goal of discharging Fast speed, easy to disassemble and clean, ensure sealing performance and safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

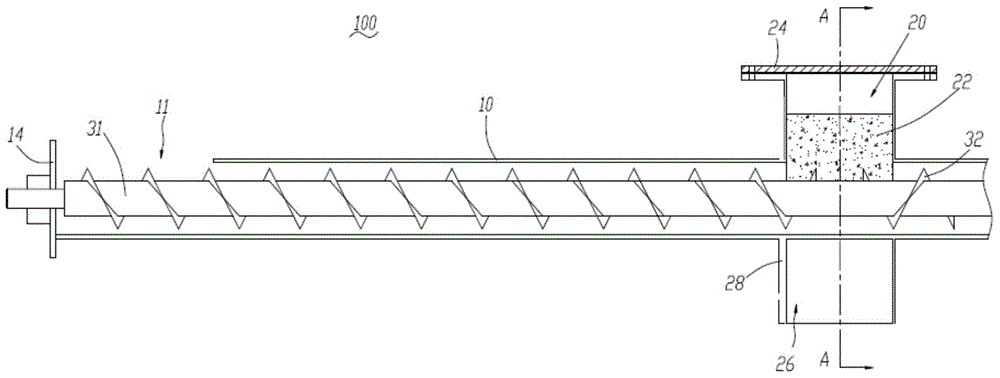

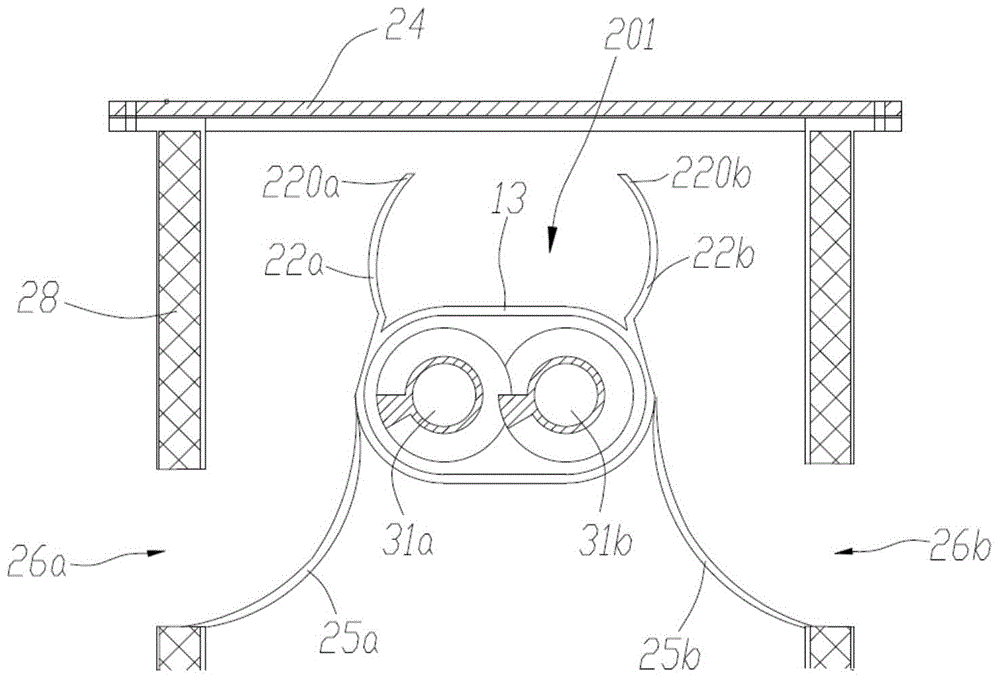

[0015] The present invention will be described in detail below in conjunction with specific embodiments shown in the accompanying drawings. The pyrolysis treatment system of the present invention can be used in the pyrolysis treatment process of waste tires, waste rubber, waste plastics, municipal domestic organic waste, sludge, medical waste and other organic polymer wastes. Taking the pyrolysis treatment process of waste tires as an example, the waste pyrolysis system at least includes: a crushing device for crushing waste tires, a pyrolysis reaction device for pyrolysis reaction of crushed tire rubber particles And a sealed material guide device for leading the pyrolysis product in the pyrolysis reaction device to the outside. Among them, the pyrolysis reaction device includes a pyrolysis reaction chamber, a material propulsion mechanism arranged in the pyrolysis reaction chamber, a heat supply unit, and an insulation layer covering the periphery of the pyrolysis reaction c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com