Preparation method and application of micro-mesoporous molecular sieve diatomite composite used for adsorption process

A composite material and diatomite sieve technology, which is applied in other chemical processes, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve the problems of weakening mass diffusion restrictions, single molecular size matching, and slow mass diffusion in pores. Achieve the effects of reducing the effect of mass diffusion limitation, improving adsorption capacity, and enriching the pore system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

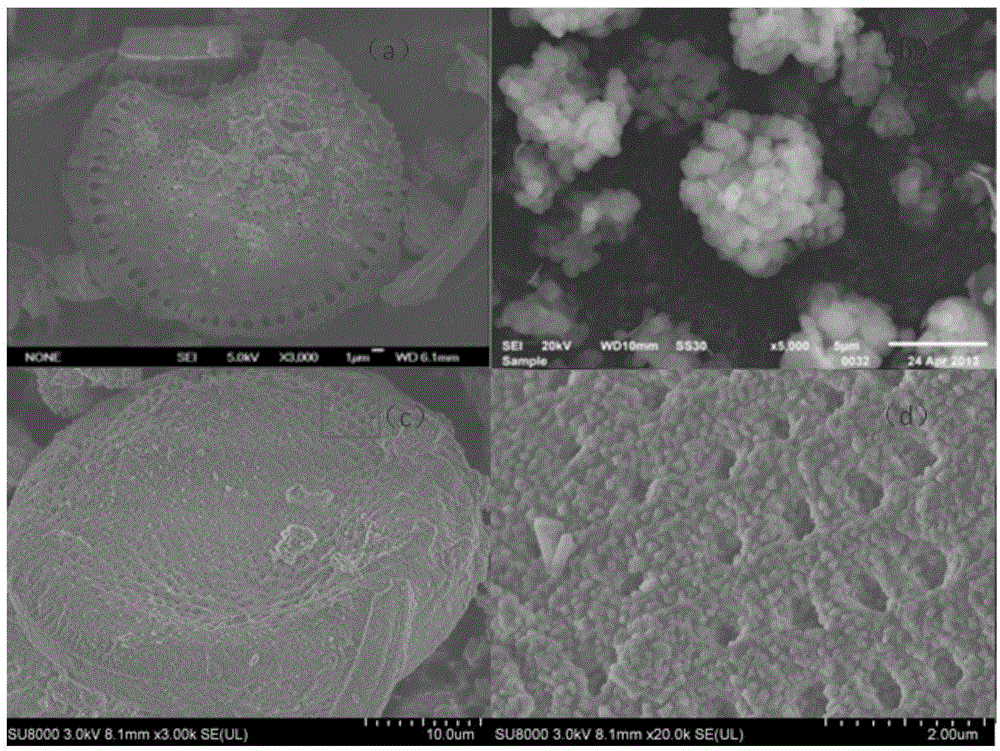

Image

Examples

example 1

[0033] a. Preparation of silicalite-1 molecular sieve seed crystals:

[0034] According to the molar ratio TPAOH:SiO 2 :H 2 The ratio of O:EtOH=9:25:480:100, namely TPAOH37.94g, TEOS27.10g, H 2 O16.49g, stirred for 24h, refluxed in an oil bath at 100°C for 48h to obtain seed crystals, took 0.5g seed crystals and dispersed them in 100ml water to make a zeolite solution with a mass fraction of 0.5%, adjusted the pH value to 10, at this time silicalite-1 seed crystals The solution is negatively charged;

[0035] b. Diatomite purification and electrical modification:

[0036] Soak 4g of diatomite in 100ml of 0.2% PDDA solution by volume fraction, wash with 0.1mol / L ammonia water several times to remove excess electrolyte, and dry with slight heat. At this time, the diatomite changes from negative charge to positive charge.

[0037] c. Diatomite adsorption seed:

[0038] The diatomite after electrical modification in step b was oscillated and adsorbed in the zeolite solution o...

example 2

[0045] a. Preparation of silicalite-1 molecular sieve seed crystals:

[0046] According to the molar ratio TPAOH:SiO 2 :H 2 The ratio of O:EtOH=9:25:480:100, namely TPAOH37.94g, TEOS27.10g, H 2 O16.49g, stirred for 24h, refluxed in an oil bath at 100°C for 48h to obtain seed crystals, took 0.5g seed crystals and dispersed them in 100ml water to make a zeolite solution with a mass fraction of 0.5%, adjusted the pH value to 10, at this time the silicalite-1 seed crystals The solution is negatively charged;

[0047] b. Diatomite purification and electrical modification:

[0048] Soak 4g of diatomite in 100ml of 0.2% PDDA solution by volume fraction, wash with 0.1mol / L ammonia water several times to remove excess electrolyte, and dry it with slight heat. At this time, the diatomite turns from negative charge to positive charge.

[0049] c. Diatomite adsorption seed:

[0050]The diatomite after electrical modification in step b was oscillated and adsorbed in the zeolite soluti...

example 3

[0057] a. Preparation of silicalite-1 molecular sieve seed crystals:

[0058] According to the molar ratio TPAOH:SiO 2 :H 2 The ratio of O:EtOH=9:25:480:100, namely TPAOH37.94g, TEOS27.10g, H 2 O16.49g, stirred for 24h, refluxed in an oil bath at 100°C for 48h to obtain seed crystals, took 0.5g seed crystals and dispersed them in 100ml water to make a zeolite solution with a mass fraction of 0.5%, adjusted the pH value to 10, at this time silicalite-1 seed crystals The solution is negatively charged;

[0059] b. Diatomite purification and electrical modification:

[0060] Soak 4g of diatomite in 100ml of 0.2% PDDA solution by volume fraction, wash with 0.1mol / L ammonia water several times to remove excess electrolyte, and dry with slight heat. At this time, the diatomite changes from negative charge to positive charge.

[0061] c. Diatomite adsorption seed:

[0062] The diatomite after electrical modification in step b was oscillated and adsorbed in the zeolite solution o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com