Multi-station baking-free brick punch forming equipment

A technology of stamping and unfired bricks, which is applied in auxiliary forming equipment, ceramic molding machines, manufacturing tools, etc., can solve the problems of uneven overall density of unfired bricks, easy occurrence of air pockets in bricks, and poor strength, and achieve The effect of consistent density, high strength and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

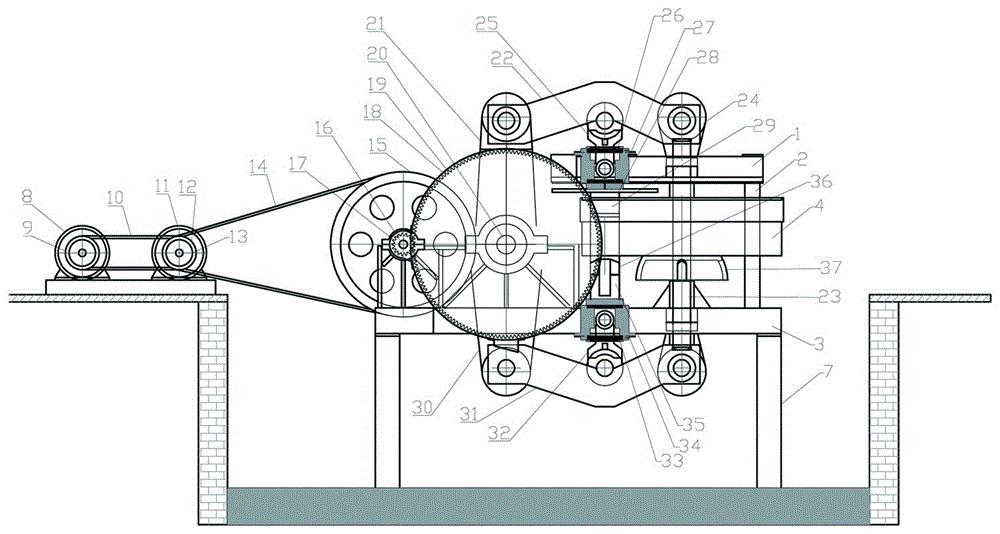

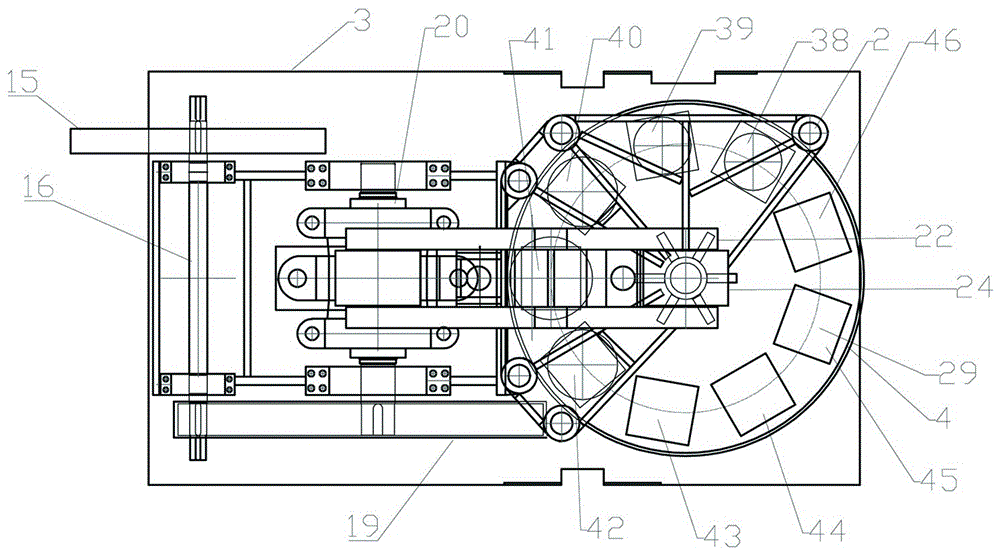

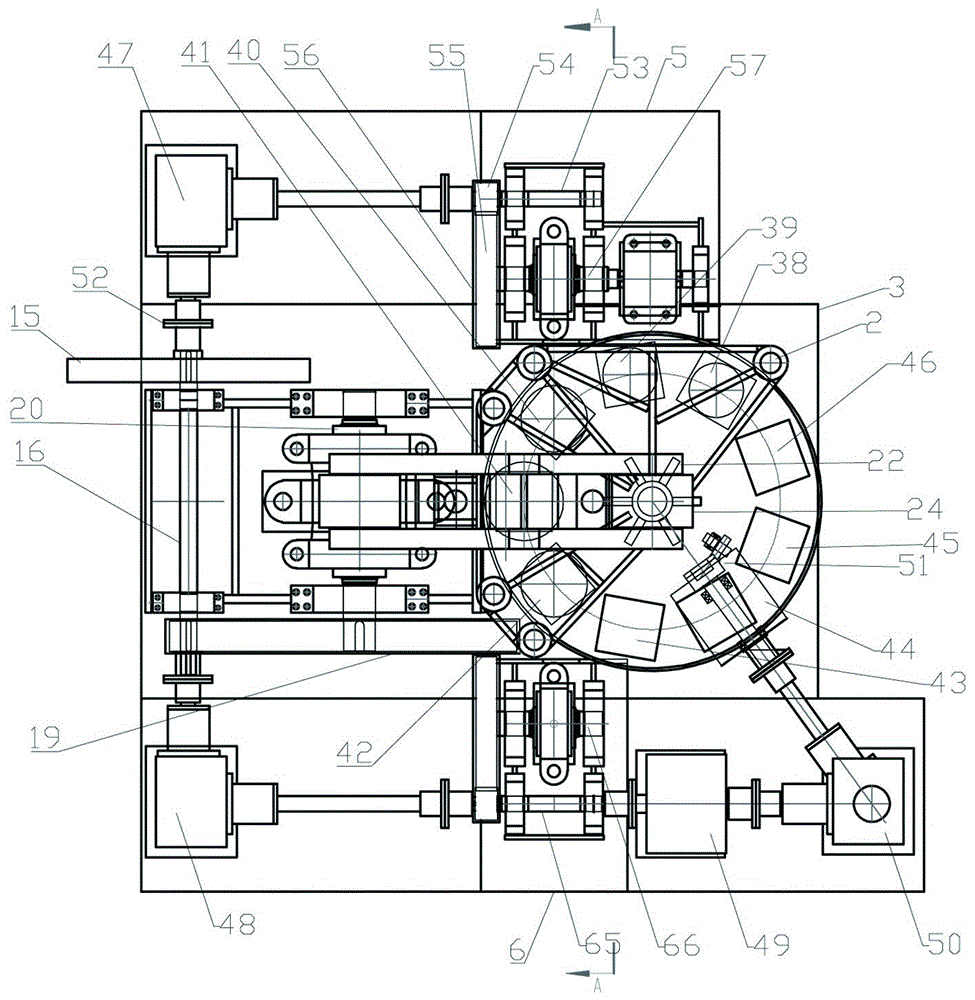

[0020] Embodiment 1: A kind of multi-station burn-free brick stamping forming equipment, such as Figure 1~4 As shown, it includes a main body seat 3, a bracket 7, an upper seat 1, a driving mechanism, a transmission mechanism, a limit mechanism and a brick pressing mechanism; the main body seat 3 is fixed on the bracket 7, and a column is arranged between the main body seat 3 and the upper seat 1 2. The driving mechanism is located on one side of the main body seat 3. The transmission mechanism, the limiting mechanism and the brick pressing mechanism are installed on the main body seat 3. The limiting mechanism includes the turntable 4 and the mold cavity 29, and the mold cavity 29 is respectively Cleaning template station 45, feeding station 46, pre-pressing station 38, low-pressure station 39, medium-pressure station 40, high-pressure station 41, demoulding station 42, brick-out station 43 and brick-picking station 44. The brick pressing mechanism includes a pre-pressing me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com