Novel assembly type composite interlayer floor and preparation method thereof

A prefabricated and interlayer technology, which is applied in the direction of floors, chemical instruments and methods, and synthetic resin layered products, can solve the problems of prefabricated reinforced concrete floors such as heavy weight, poor heat insulation and sound insulation, and unfavorable structural earthquake resistance. , to achieve the effect of being conducive to the seismic requirements of the structure, light weight and shortening the construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

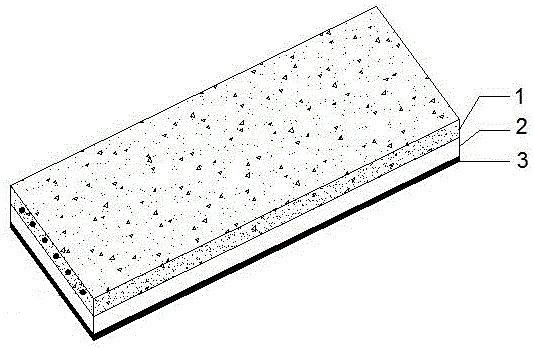

[0016] According to the design requirements of the architectural plan, a floor slab adopts the new type of prefabricated composite sandwich floor slab of the present invention, and the structural diagram is as follows figure 1 As shown, the prefabricated composite mezzanine floor is divided into three layers along the vertical direction, and from top to bottom are reinforced concrete slab surface layer 1, polystyrene foam (EPS) core layer 2 (provided by Shenzhen Guojing Packaging Materials Co., Ltd. Co., Ltd.), glass fiber reinforced plastic (GFRP) surface layer 3 (Dongguan Juli Fiberglass Products Co., Ltd.). The floor bears a uniformly distributed load of 6 kN / m 2 , the floor is 3.6m long and 1.2m wide. The total design thickness is 103.04mm, of which the upper reinforced concrete (C30) slab surface layer is 75mm, the middle polystyrene foam (EPS) core layer is 25mm, and the lower glass fiber reinforced plastic (GFRP) surface layer is 3.04mm. The comparison plate adopts 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com