Environment-friendly waste PE material and preparation method thereof, and modified environment-friendly waste PE material prepared therefrom and preparation method thereof

A waste and environmental protection technology, applied in the field of environmentally friendly waste PE materials and their preparation, modified environmentally friendly waste PE materials and their preparations, can solve the problems of being unable to find, weakening of PE material performance, difficult to degrade PE plastics, etc., to broaden the scope of application and improve performance , the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

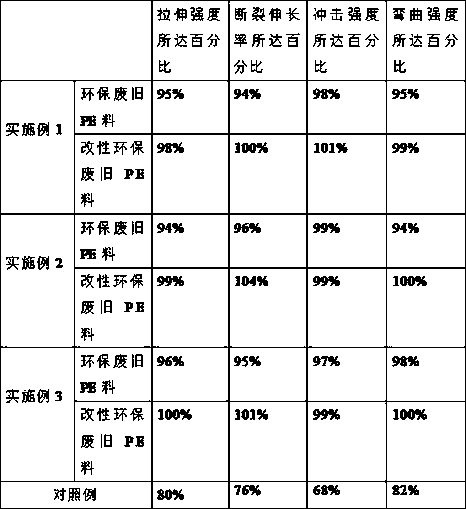

Examples

Embodiment 1

[0026] The preparation method of environment-friendly waste PE material comprises the following steps:

[0027] Step 1, one-time washing: Soak the recovered PE waste in water at a temperature of 45°C for 3 hours, filter out the water, and obtain one-time washing of PE waste;

[0028] Step 2, secondary water washing: crush the primary water-washed PE waste obtained in step 1 into granular form, and rinse with high-pressure water for 8 minutes to obtain secondary water-washed PE waste;

[0029] Step 3, drying: vacuum-dry the secondary washed PE waste obtained in Step 2 to obtain dried PE waste. The vacuum degree of vacuum drying is 0.7-5MPa, and the temperature is 43°C;

[0030] Step 4, cleaning of treatment solution Ⅰ: immerse the dried PE waste obtained in step 3 into treatment solution Ⅰ, raise the temperature to 42°C, stir at a constant temperature for 40 minutes at a constant speed of 100 r / min, and filter the PE waste to obtain a primary treatment of PE waste, of which Th...

Embodiment 2

[0035] The preparation method of environment-friendly waste PE material comprises the following steps:

[0036] Step 1, one-time washing: Soak the recovered PE waste in water at a temperature of 40°C for 4 hours, filter out the water, and obtain one-time washing of PE waste;

[0037] Step 2, secondary water washing: crush the primary water-washed PE waste obtained in step 1 into granular form, and rinse with high-pressure water for 5 minutes to obtain secondary water-washed PE waste;

[0038] Step 3, drying: vacuum-dry the secondary washed PE waste obtained in Step 2 to obtain dried PE waste. The vacuum degree of vacuum drying is 0.7 MPa and the temperature is 45°C;

[0039] Step 4, cleaning of treatment solution Ⅰ: immerse the dried PE waste obtained in step 3 into treatment solution Ⅰ, raise the temperature to 40°C, stir at a constant temperature for 50 minutes at a constant speed of 100 r / min, and filter the PE waste to obtain a primary treatment of PE waste, of which The ...

Embodiment 3

[0044] The preparation method of environment-friendly waste PE material comprises the following steps:

[0045] Step 1, one-time washing: Soak the recovered PE waste in water at a temperature of 50°C for 4 hours, filter out the water, and obtain one-time washing of PE waste;

[0046] Step 2, secondary water washing: crush the primary water-washed PE waste obtained in step 1 into granular form, and rinse with high-pressure water for 10 minutes to obtain secondary water-washed PE waste;

[0047] Step 3, drying: vacuum-dry the secondary washed PE waste obtained in Step 2 to obtain dried PE waste. The vacuum degree of vacuum drying is 0.8 MPa and the temperature is 40°C;

[0048] Step 4, cleaning of treatment solution Ⅰ: immerse the dried PE waste obtained in step 3 into treatment solution Ⅰ, raise the temperature to 45°C, stir at a constant temperature for 30 minutes at a constant speed of 150 r / min, filter the PE waste, and obtain a primary treatment of PE waste, of which The t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com