High-hardness non-stick coating with effect similar to shot blasting effect and preparation method thereof

A non-stick coating and coating technology, which is applied in coatings, devices for coating liquid on the surface, applications, etc., can solve the problems of complex shot blasting process, high cost, and large resource consumption of pots, and achieve good results. Non-stick effect, excellent wear resistance, high hardness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

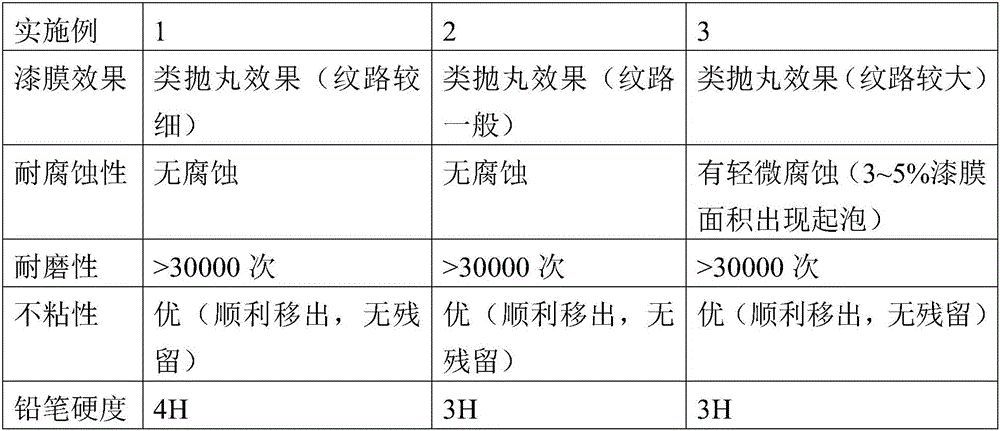

Examples

Embodiment 1

[0049] The applicant provides a non-stick coating imitating shot blasting effect, comprising primer, middle coat and top coat, a kind of coating similar to shot blasting effect is obtained after primer curing, and middle coat provides Links the action of the base coat and the top coat, the top coat provides non-stick properties.

[0050] (1) The undercoat material is made up of the following raw materials in parts by weight:

[0051] PES resin: 15 parts;

[0052] PAI resin: 5 parts

[0053] Pigment: 1 part;

[0054] PEEK resin: 15 parts;

[0055] Filling: 3 parts;

[0056] Solvent A: 40 parts;

[0057] Auxiliary A: 0.5 parts.

[0058] The solvent A of the undercoat is made up of the following raw materials in percentage by weight: 60% of propylene glycol, 25% of isopropanol, 15% of deionized water; the filler of the undercoat is silicon carbide fine powder (particle diameter is 1200 mesh ); The auxiliary agent A is DisponilSDS 15 reactive emulsifier.

[0059] The prepa...

Embodiment 2

[0088] The applicant provides a non-stick coating imitating shot blasting effect, comprising primer, middle coat and top coat, a kind of coating similar to shot blasting effect is obtained after primer curing, and middle coat provides Links the action of the base coat and the top coat, the top coat provides non-stick properties.

[0089] (1) The undercoat material is made up of the following raw materials in parts by weight:

[0090] PES resin: 15 parts;

[0091] PAI resin: 10 parts;

[0092] Pigment: 2 parts;

[0093] PEEK resin: 18 parts;

[0094] Filling: 4 parts;

[0095] Solvent A: 45 parts;

[0096] Auxiliary A: 0.5 part.

[0097] The polymer resin is polyether sulfone or PES, and the solvent A of the primer layer is made up of the following raw materials in percentage by weight: propylene glycol 60%, isopropanol 30%, deionized water 10%; The filler is 1200 mesh silicon carbide fine powder; the auxiliary agent A of the primer layer is Disponil SDS 15 reactive emul...

Embodiment 3

[0128] The applicant provides a non-stick coating imitating shot blasting effect, comprising primer, middle coat and top coat, a kind of coating similar to shot blasting effect is obtained after primer curing, and middle coat provides Links the action of the base coat and the top coat, the top coat provides non-stick properties.

[0129] (1) The undercoat material is made up of the following raw materials in parts by weight:

[0130] PES resin: 15 parts;

[0131] PAI resin: 15 parts;

[0132] Pigment: 3 parts;

[0133] PEEK resin: 20 parts;

[0134] Filling: 5 parts;

[0135] Solvent A: 50 parts;

[0136] Auxiliary A: 1 part.

[0137] The polymer resin is polyether sulfone or PES, and the solvent A of the primer layer is made up of the following raw materials in percentage by weight: propylene glycol 55%, isopropanol 30%, deionized water 15%; The filler is silicon carbide fine powder (1200 mesh); the auxiliary agent A of the primer layer is Disponil SDS 15 reactive emul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com