Chilling split type dry coal powder gasifying furnace

A gasifier, split-type technology, applied in coke gasification, coal chemical industry, can solve the problems of increased consumption of manpower and material resources, high equipment and civil construction costs, large investment in pulverized coal gasification, etc., to achieve shortened construction period, project Reduced investment cost and good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention is described in detail below with reference to accompanying drawing:

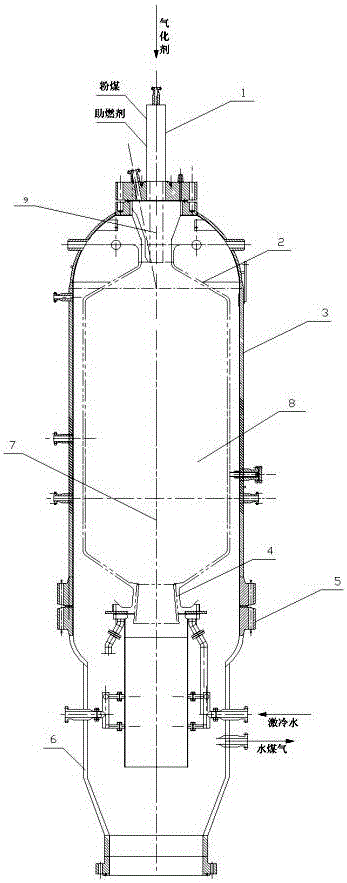

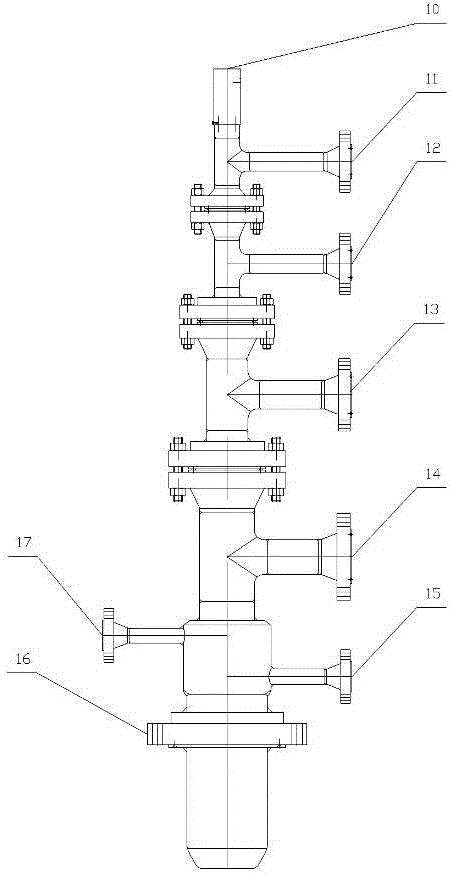

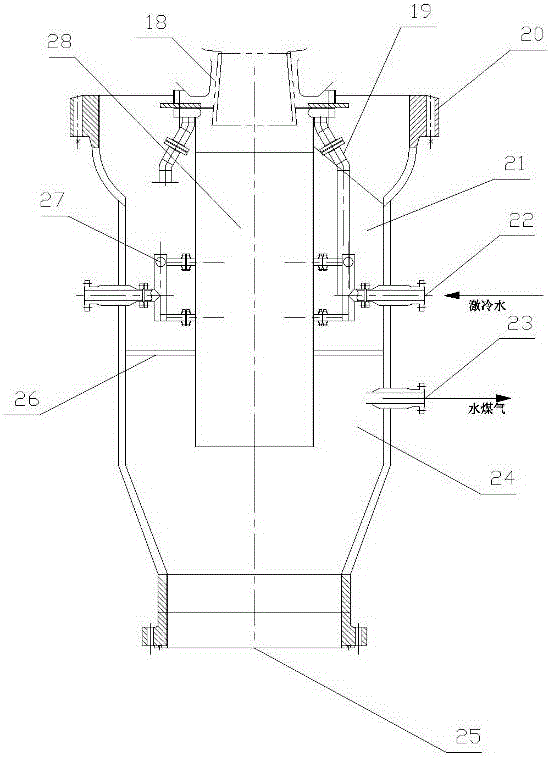

[0035] Such as figure 1 As shown, a kind of quenching split-type gasifier implemented according to the present invention comprises a gasifier hearth 8, a burner 1, and a quenching chamber 6;

[0036] The gasifier hearth 8 includes a shell 3, a furnace inlet 9, a furnace outlet 5, a combustion chamber 7 and a water wall 2, the furnace inlet 9 is connected to the burner 1, and the furnace outlet 5 is connected to the quenching The large flange 20 at the entrance of the chamber is connected;

[0037] The gasification agent and dry coal powder are mixed through the nozzle 1 and enter the gasifier furnace 8 to fully burn and gasify to produce water gas. The water gas exits the gasifier furnace 4 and enters the quenching chamber 6, where it is directly mixed with the quenching water to cool the water gas, and at the same time settles and separates the ash After entering the lock bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com