A kind of antirust emulsion with high oil phase content and preparation method thereof

A technology of anti-rust emulsion and high oil phase, which is applied in the petroleum industry, lubricating compositions, etc. It can solve the problems of reducing the viscosity of the emulsion, failure of protection, and difficult fusion of droplets, so as to reduce carbon emissions, avoid pollution, and have strong adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

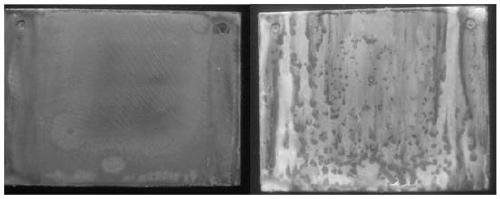

Image

Examples

Embodiment 1

[0044] The antirust emulsion with high oil phase content of the present embodiment is composed of the following components by weight percentage:

[0045] 18% microcrystalline wax

[0046] 37% 68# white oil

[0047] 9% oxidized petrolatum

[0048] 3% fatty alcohol polyoxyethylene ether 12

[0049] 33% water

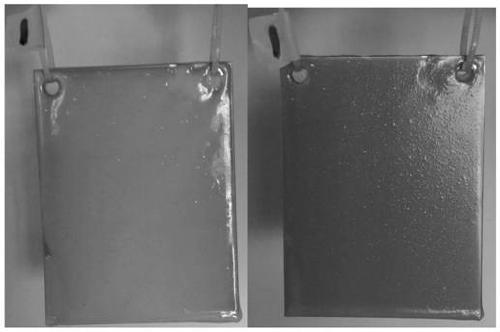

[0050] Mix the wax, base oil, antirust agent and emulsifier evenly according to the above formula, heat and melt to form a mixture; add the above mixture into hot water at 80-95°C under stirring conditions, emulsify, neutralize, stir and cool To the antirust emulsion of this embodiment. The antirust emulsion of this embodiment has the following properties: emulsion type: oil-in-water; system solid content: 67%; the result of the neutral salt spray test of the antirust emulsion in embodiment 1 is: 0 grade after 240 hours, as attached figure 2 shown.

Embodiment 2

[0052] The antirust emulsion with high oil phase content of the present embodiment is composed of the following components by weight percentage:

[0053] 18% microcrystalline wax

[0054] 33% naphthenic oil

[0055] 6% oxidized petrolatum

[0056] 4% fatty alcohol polyoxyethylene ether 8

[0057] 39% water

[0058] Mix the wax, base oil, antirust agent and emulsifier evenly according to the above formula, heat and melt to form a mixture; add the above mixture into hot water at 80-95°C under stirring conditions, emulsify, neutralize, stir and cool To the antirust emulsion of this embodiment. The anti-rust emulsion of this embodiment has the following properties: emulsion type: oil-in-water; system solid content: 61%; the result of the neutral salt spray test of the anti-rust emulsion in embodiment 2 is: 0 grade after 240 hours, as attached image 3 shown.

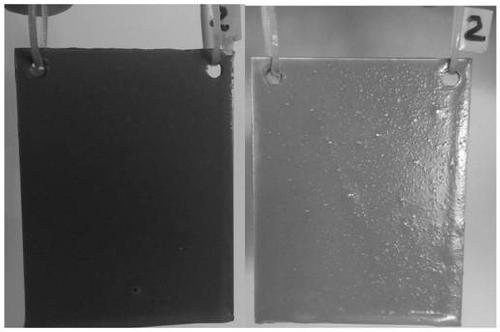

Embodiment 3

[0060] The antirust emulsion with high oil phase content of the present embodiment is composed of the following components by weight percentage:

[0061] 18% micro-mixed crystalline wax

[0062] 27.2% 68# white oil

[0063] 9% oxidized petrolatum

[0064] 4.5% fatty alcohol polyoxyethylene ether 6

[0065] 41.3% water

[0066] Mix the wax, base oil, antirust agent and emulsifier evenly according to the above formula, heat and melt to form a mixture; add the above mixture into hot water at 80-95°C under stirring conditions, emulsify, neutralize, stir and cool To the antirust emulsion of this embodiment. The antirust emulsion of this embodiment has the following properties: emulsion type: oil-in-water; system solid content: 58.7%; embodiment 3 antirust emulsion carries out neutral salt spray test result: 0 level after 240 hours, as attached Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com