1-methylcyclopropene preservative paper and preparation method thereof

A technology of methylcyclopropene and fresh-keeping paper, which is applied in the fields of fruit and vegetable fresh-keeping, paper, papermaking, etc. It can solve the problems of difficult large-scale rapid storage, inconvenient use, complicated operation, etc., and achieve easy control of product quality and environmental protection in the production process , The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

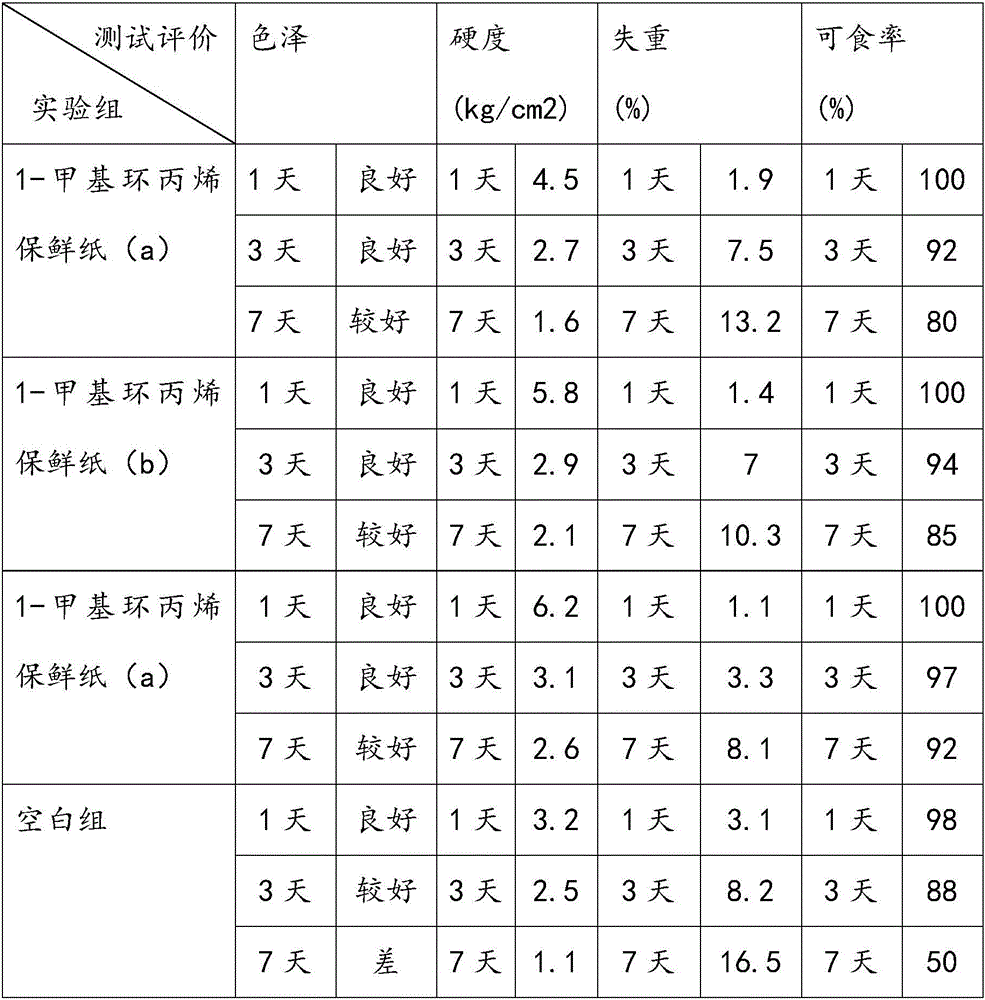

Examples

Embodiment 1

[0024] Step 1: degrade amylose by a-amylase, control the degree of polymerization at 100, and then undergo substitution reaction with 2,3-epoxypropyltrimethylammonium chloride, control the degree of substitution to 0.1 to obtain modified amylose .

[0025] Step 2, preparation of 1-methylcyclopropene inclusion complex: pass 1-MCP gas into the 8% modified amylose solution obtained in step 1, adjust pH=4 and temperature 5°C, and precipitate 1 -Starch crystals of MCP, the mass percentage of 1-MCP in the inclusion complex is controlled to be 0.10%.

[0026] Step 3, preparation of coating: Weigh 100 parts of starch crystals obtained in step 2, and weigh 8 parts of water-absorbing agent, 5 parts of dispersant, and 5 parts of slow-release agent, add polyethylene glycol with an average molecular weight of 4000, and heat In the melt, stir and disperse at 800r / min, and put it into the paint storage barrel for later use.

[0027] Step 4, preparation of base paper layer: take bamboo pulp...

Embodiment 2

[0031] Step 1: degrade amylose by a-amylase, control the degree of polymerization at 150, and then undergo substitution reaction with 2,3-epoxypropyltrimethylammonium chloride, control the degree of substitution to 0.3 to obtain modified amylose .

[0032] Step 2, preparation of 1-methylcyclopropene inclusion complex: 1-MCP gas is passed into the 10% modified amylose solution obtained in step 1, and the pH is adjusted to 4.5 and the temperature is 10°C, and the encapsulation 1 -MCP starch crystals, the mass percentage of 1-MCP in the inclusion complex is controlled to be 0.12%.

[0033] Step 3, preparation of coating: Weigh 100 parts of starch crystals obtained in step 2, and weigh 10 parts of water-absorbing agent, 8 parts of dispersant, and 8 parts of slow-release agent, add polyethylene glycol with an average molecular weight of 4000, and heat In the melt glue, stir and disperse at 900r / min, and put it into the paint storage barrel for later use.

[0034] Step 4, preparat...

Embodiment 3

[0038] Step 1: degrade amylose by a-amylase, control the degree of polymerization at 200, and then undergo substitution reaction with 2,3-epoxypropyltrimethylammonium chloride, control the degree of substitution to 0.5 to obtain modified amylose .

[0039] Step 2, preparation of 1-methylcyclopropene inclusion complex: 1-MCP gas is passed into the 12% modified amylose solution obtained in step 1, and the pH is adjusted to 5.0 and the temperature is 10°C, and the encapsulation 1 -Starch crystals of MCP, the mass percentage of 1-MCP in the inclusion complex is controlled to be 0.16%.

[0040] Step 3, preparation of coating: Weigh 100 parts of starch crystals obtained in step 2, and weigh 15 parts of water-absorbing agent, 10 parts of dispersant, and 10 parts of slow-release agent, add polyethylene glycol with an average molecular weight of 4000, and heat In the melt, stir and disperse at 700r / min, and put it into the paint storage bucket for later use.

[0041] Step 4, preparat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com