Liquefied natural gas receiving station evaporation gas direct output process and device

A technology of liquefied natural gas and boil-off gas, which is applied in fixed-capacity gas storage tanks, gas/liquid distribution and storage, pressure vessels, etc., can solve the problems of wasting high-pressure liquefied natural gas pressure and reduce high-pressure natural gas, and achieve outstanding energy-saving effects and energy The effect of low consumption and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

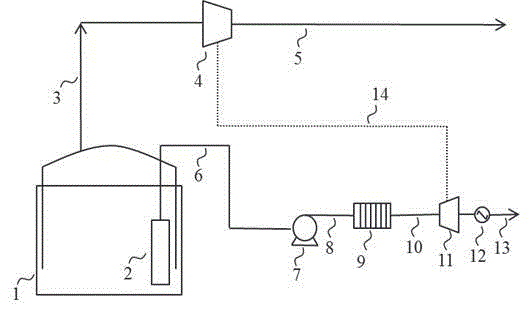

[0058] Embodiment 1 adopts figure 1 process shown. The BOG compressor is driven by the work of the expander.

[0059] In an LNG receiving station, 9MPa natural gas is supplied to high-pressure natural gas users. The molar composition of LNG is as follows: methane 88.77%, ethane 7.54%, propane 2.59%, isobutane 0.45%, n-butane 0.56%, nitrogen 0.08%. With 2 seats 16×10 4 m 3 The LNG storage tank, the boiling point of LNG under normal pressure is -162°C, and the density is 456kg / m 3 For example, the total amount of cargo stored in each storage tank (assuming the storage tank is full) is 72960t. The daily evaporation of the storage tank is less than 0.05%, so the amount of evaporated gas produced in the two storage tanks is 3.04t / h. The operating pressure of the storage tank is 0.150MPa, and the output of LNG is 200t / h. The LNG is pressurized to 1.1MPa by the low-pressure submersible pump and then enters the buffer tank. Calculated by HYSYS, the present invention needs to pres...

Embodiment 2

[0062] Embodiment 2 adopts figure 1 process shown.

[0063] In an LNG receiving station, 8MPa natural gas is supplied to high-pressure natural gas users, and 4MPa natural gas is supplied to medium-high pressure users. The molar composition of LNG is as follows: methane 88.77%, ethane 7.54%, propane 2.59%, isobutane 0.45%, normal Butane 0.56%, nitrogen 0.08%. With 2 seats 16×10 4 m 3 The LNG storage tank, the boiling point of LNG under normal pressure is -162°C, and the density is 456kg / m 3 For example, the total amount of cargo stored in each storage tank (assuming the storage tank is full) is 72960t. The daily evaporation of the storage tank is less than 0.05%, so the amount of evaporated gas produced in the two storage tanks is 3.04t / h. The operating pressure of the storage tank is 0.150MPa, and the output of LNG is 200t / h. The LNG is pressurized to 1.1MPa by the low-pressure submersible pump and enters the buffer tank. Calculated by HYSYS, the present invention needs t...

Embodiment 3

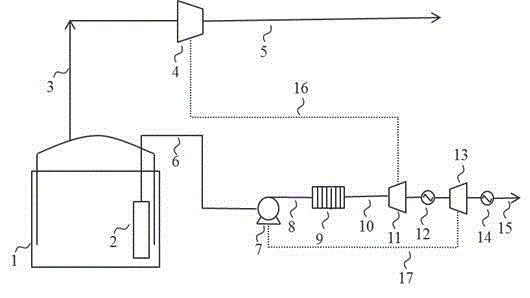

[0066] Embodiment 3 adopts figure 2 process shown. Among them, the BOG compressor is driven by the work of the first-stage expander, and the LNG high-pressure pump is driven by the work of the second-stage expander.

[0067] In an LNG receiving station, 6MPa natural gas is supplied to high-pressure natural gas users, and 5MPa natural gas is supplied to medium-high pressure users. The molar composition of LNG is as follows: methane 88.77%, ethane 7.54%, propane 2.59%, isobutane 0.45%, normal Butane 0.56%, nitrogen 0.08%. With 2 seats 16×10 4 m 3 The LNG storage tank, the boiling point of LNG under normal pressure is -162°C, and the density is 456kg / m 3 For example, the total amount of cargo stored in each storage tank (assuming the storage tank is full) is 72960t. The daily evaporation of the storage tank is less than 0.05%, so the amount of evaporated gas produced in the two storage tanks is 3.04t / h. The operating pressure of the storage tank is 0.150MPa, and the output o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com