PCBA intelligent burning equipment

A programming device and intelligent technology, applied in the direction of conveyor objects, software deployment, instruments, etc., can solve the problems of being unable to adapt to the production status of multiple varieties and small batches, missing and wrong programming, and low degree of automation, and achieve Improve production flexibility, eliminate omissions, and achieve high programming yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

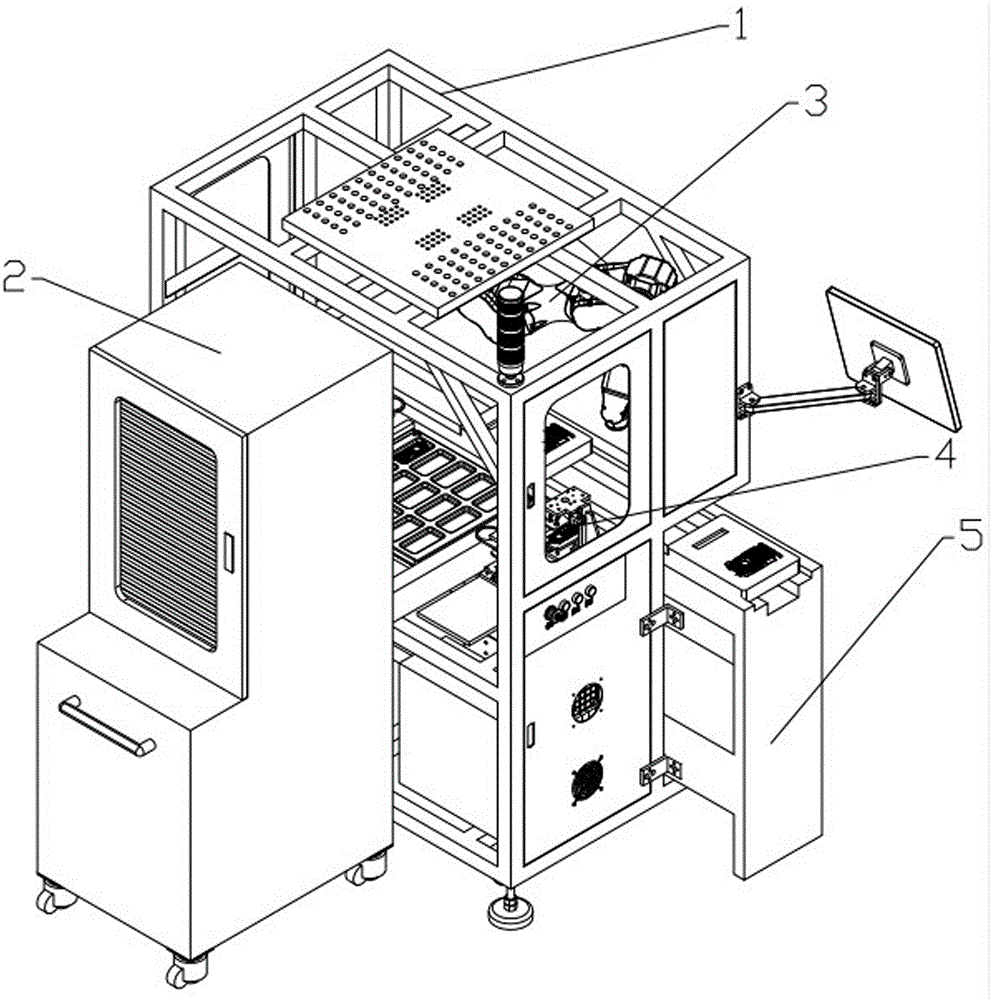

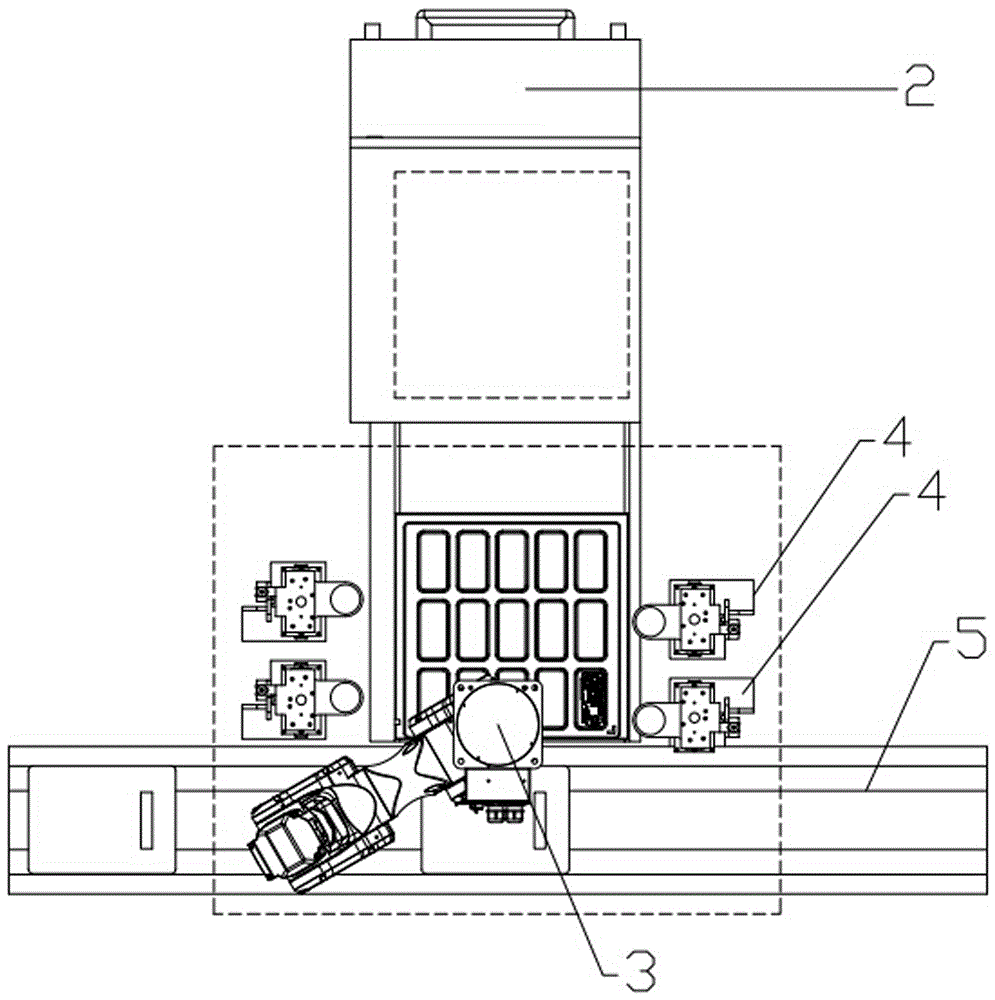

[0046] like figure 2As shown, a PCBA intelligent programming device includes: equipment rack 1; feeder 2; robot 3 for picking up, rotating and placing PCBA; multiple automatic programming fixtures 4 for positioning PCBA, burning, and feedback burning results; intelligent assembly line body 5, used to reject defective products, output materials; and control system; the control system is preferably but not limited to MES; the feeder 2, robot 3, automatic The programming fixture 4 and the intelligent assembly line body 5 are fixedly installed on the equipment rack 1 and communicated with the control system; Robot 3 is adjusted within the effective working range.

[0047] As a preferred embodiment, the robot 3 is preferably, but not limited to, fixedly installed on the top of the equipment rack 1 in a suspended manner. This suspended installation method makes the equipment compact in structure and can make full use of the arm space of the robot 3; the feeder 2 is fixed On the r...

Embodiment 2

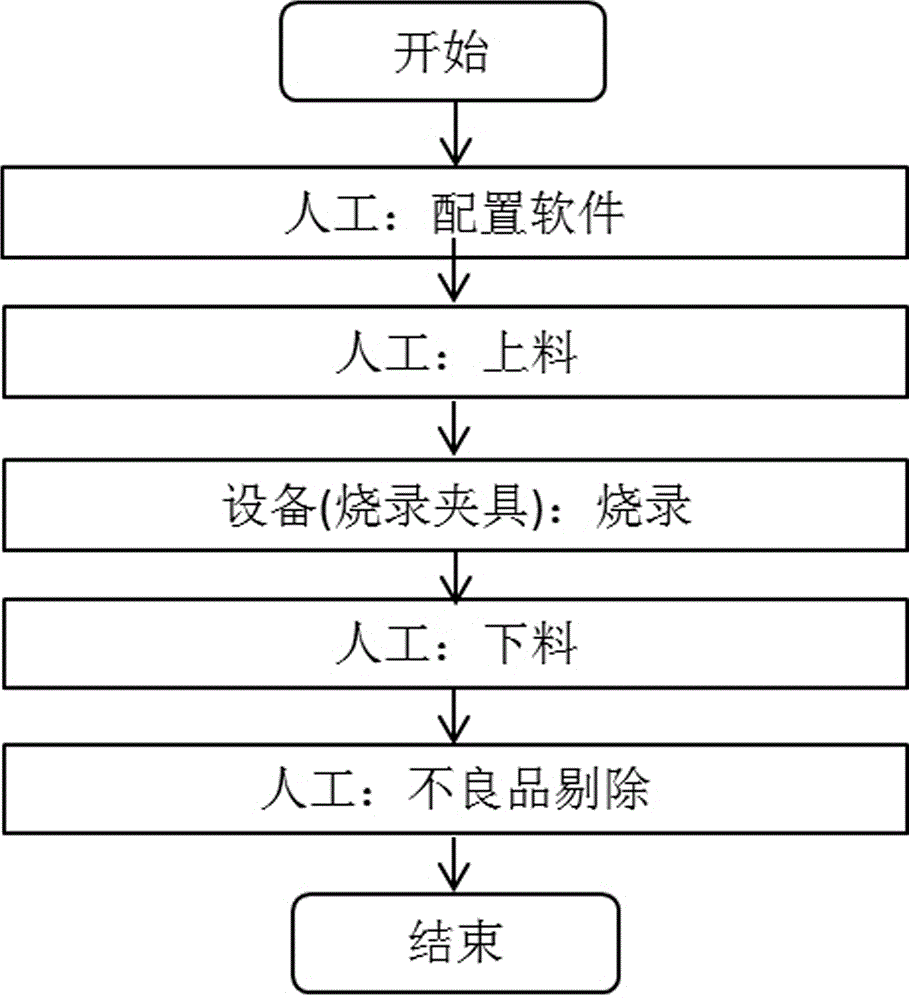

[0066] The workflow of PCBA intelligent programming equipment includes the following steps:

[0067] 1. Loading: The feeder locates and pulls out the specified tray according to the work order instruction of the MES system, and the robot starts from

[0068] Pick up the PCBA from the tray and put it into the programming fixture to position and press the test probe;

[0069] 2. Configuration software: MES system automatically configures the software version to be burned;

[0070] 3. Burning: The MES system work order command controls the burning fixture to automatically burn the specified version of the software and detect the actual

[0071] Return the burning result at any time;

[0072] 4. Cutting: The robot takes out the PCBA from the programming fixture and puts it into the assembly line carrier;

[0073] 5. Rejection of defective products: the RFID reader in the assembly line writes the burning result into the RFID card of the corresponding vehicle,

[0074] The assem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com