1.7mum all-optical-fiber thulium-doped quartz optical-fiber laser based on two-directional pumping structure

A quartz fiber and laser technology, used in lasers, laser parts, phonon exciters, etc., can solve the problems of short gain fiber length, incomplete absorption of pump light, low doping concentration, etc., and achieve simple and compact structure. High pump light absorption efficiency and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

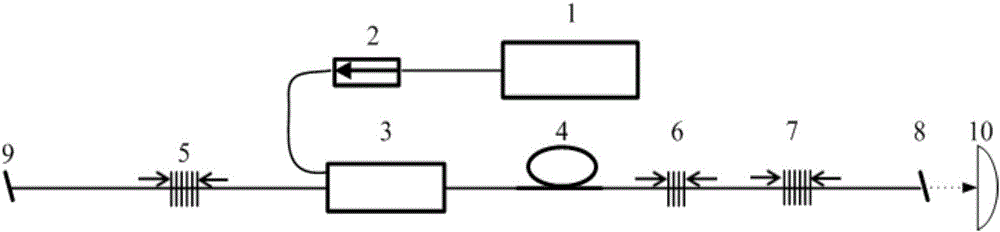

[0019] see figure 1 , the 1.7 μm all-fiber thulium-doped silica fiber laser structure based on the bidirectional pumping structure provided by the present invention includes a pump source 1, an isolator 2, a wavelength division multiplexer 3 (WDM), a thulium-doped silica fiber 4, a fiber Bragg Grating A 5, fiber Bragg grating B 6, fiber Bragg grating C 7, fiber jumper connector a 8, fiber jumper connector b 9 and filter 10; where the pump source 1 is welded to the isolator 2, and the wavelength division multiplexer The pumping arm, signal injection end and beam combining end of 3 respectively correspond to the fusion splice isolator 2, fiber Bragg grating A 5, and thulium-doped silica fiber 4; C 7. Fiber jumper head a 8 is welded; the other end of fiber Bragg grating A 5 is welded with fiber jumper head b 9.

[0020] The pumping source 1 can adopt the 1550nm erbium-doped fiber laser produced by IPG Laser Company, the maximum output power is 20W; the insertion loss of the opti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com