Lactic acid bacterium collagen jelly and manufacture method thereof

A collagen and lactic acid bacteria technology, applied in the food field, can solve the problem of single species, and achieve the effect of soft and moderate tissue, uniform texture and smooth taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

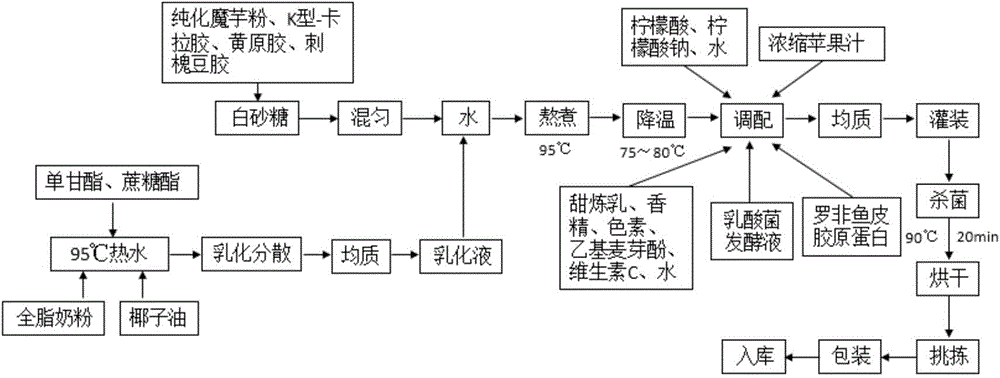

[0030] The manufacture of embodiment 1 lactic acid bacteria collagen jelly

[0031] The lactic acid bacteria collagen jelly of the present embodiment is manufactured based on the following formula: white granulated sugar 10wt%, sweetened condensed milk 1wt%, whole milk powder 1.5wt%, hydrogenated coconut oil 1wt%, purified konjac powder 0.15wt%, Kappa type-carrageenan 0.2wt %, xanthan gum 0.05wt%, locust bean gum 0.08wt%, tilapia skin collagen peptide 4wt%, lactic acid bacteria fermentation broth 5wt%, monoglyceride 0.05wt%, sucrose ester 0.05wt%, potassium dihydrogen phosphate 0.25 wt%, 0.2wt% citric acid, 0.15wt% sodium citrate, 0.05wt% ethyl maltol, 0.025wt% vitamin C, 3wt% concentrated apple juice, and the balance is 76.32wt% water.

[0032] By the following methods, the lactic acid bacteria collagen jelly of the present embodiment has been manufactured:

[0033] (1) Preparation of lactic acid bacteria fermentation broth: use skimmed milk powder and glucose as raw materials...

Embodiment 2

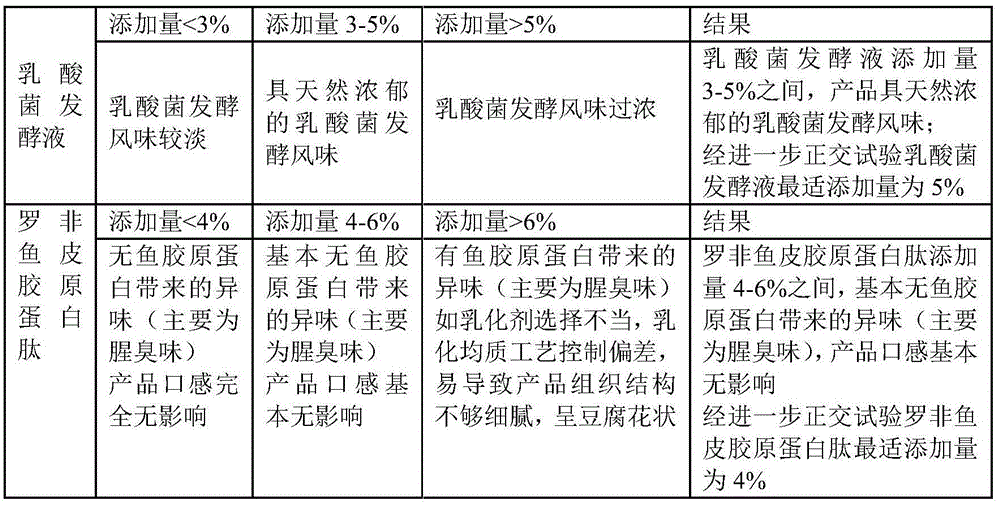

[0045] Embodiment 2 Evaluation of lactic acid bacteria collagen jelly local flavor and mouthfeel

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com