Preparation method of gangue composite catalyst, and application of catalyst in catalytic pyrolysis

A technology for catalytic pyrolysis and coal gangue, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, petroleum industry and other directions, which can solve the problems of limited application and high cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

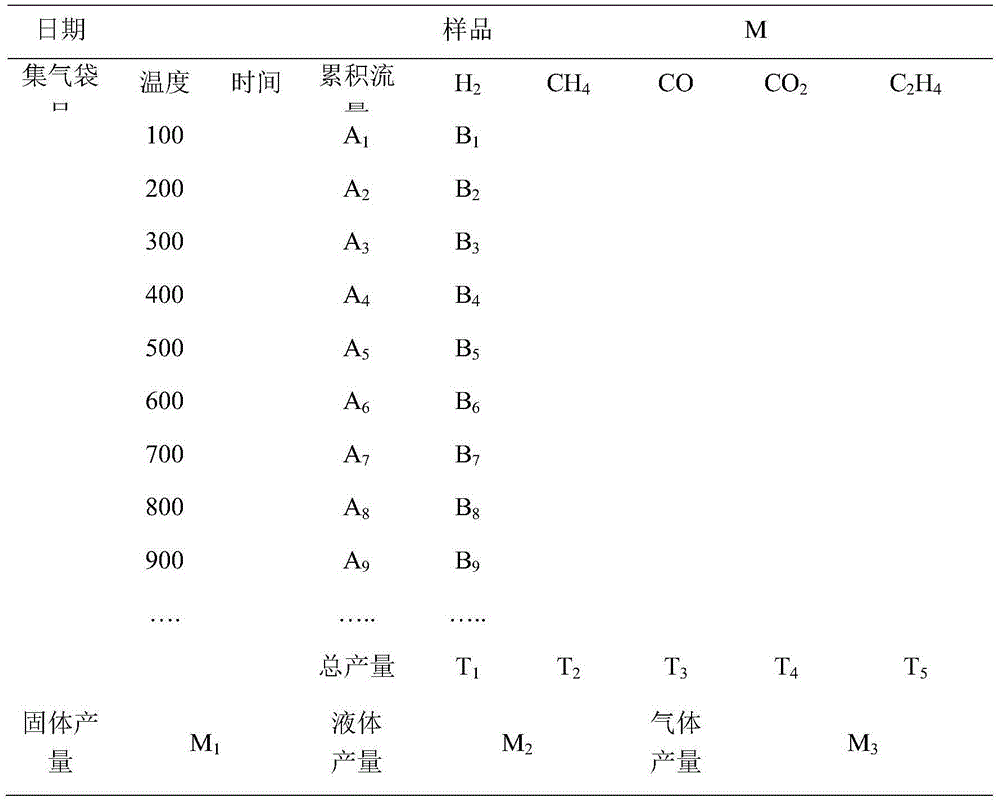

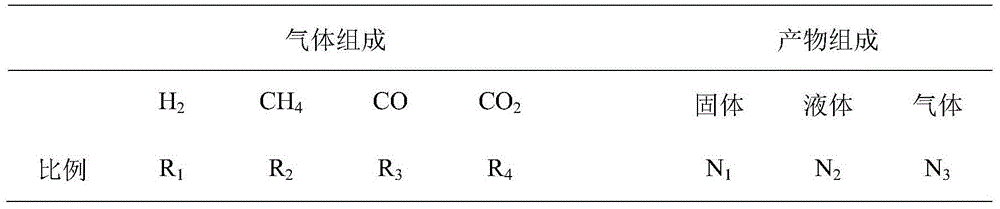

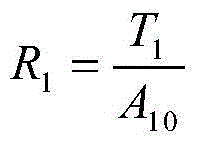

Image

Examples

Embodiment 1

[0027] (1) Weigh 55.2g of coal gangue, calcine and activate it in a muffle furnace or a fixed-bed reactor, the calcination temperature is 490°C, the calcination time is 5h, and the coal gangue with a particle size of 2-10mm is screened out as activated coal Gangue matrix;

[0028] (2) Take an appropriate amount of acetate by weighing 8% of the ratio of the active component in the catalyst, wherein nickel acetate 6.8g, manganese acetate 7.1g, magnesium acetate 14.3g, the required metal acetate is dissolved in an appropriate amount of In deionized water, make a metal salt solution as an impregnating solution;

[0029] (3) Soak the activated coal gangue matrix in metal salt solution, immerse at 55°C for 24h, filter and dry at 105°C for 15h in a vacuum drying oven;

[0030] (4) Put the dry sample into the furnace and bake it at 450° C. for 4 hours to prepare the coal gangue composite catalyst.

[0031] The prepared coal gangue composite catalyst was added to domestic garbage, co...

Embodiment 2

[0039] (1) Weigh 55.2g of coal gangue, calcining and activating the coal gangue in a muffle furnace or a fixed bed reactor, the activation temperature is 540°C, the activation time is 5h, and the coal gangue with a particle size of 2-10mm is screened out, As an activated coal gangue matrix;

[0040] (2) Take an appropriate amount of acetate by weighing 8% of the ratio of the active component in the catalyst, wherein nickel acetate 6.8g, manganese acetate 7.1g, magnesium acetate 14.3g, the required metal acetate is dissolved in a certain amount of deionized water, prepared as an impregnating solution;

[0041] (3) Immerse the activated coal gangue matrix in the metal acetate solution, soak for 24 hours at a temperature of 65° C., put it into a vacuum drying oven after filtering, and dry it for 16 hours at a temperature of 105° C.;

[0042] (4) Further calcining at a temperature of 500° C. for 6 hours to prepare a coal gangue composite catalyst.

Embodiment 3

[0044] (1) Weigh 55.2g of coal gangue, carry out calcination and activation treatment in a muffle furnace or fixed bed reactor, the activation temperature is 580°C, the activation time is 6h, and the coal gangue with a particle size of 2 to 10mm is screened out as the activated gangue matrix;

[0045] (2) Take an appropriate amount of acetate by weighing 8% of the ratio of the active component in the catalyst, wherein nickel acetate 6.8g, manganese acetate 7.1g, magnesium acetate 14.3g, the required metal acetate is dissolved in a certain amount of deionized water, prepared as an impregnating solution;

[0046] (3) Soak the activated coal gangue matrix in the acetate solution, soak it for 24 hours at a temperature of 60°C, and dry it in a vacuum oven at 105°C for 18 hours after filtering;

[0047] (4) Further calcining at a temperature of 700°C for 6 hours can be made into a coal gangue composite catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com