A kind of p-n heterojunction bivo4/mos2 composite photocatalyst and preparation method thereof

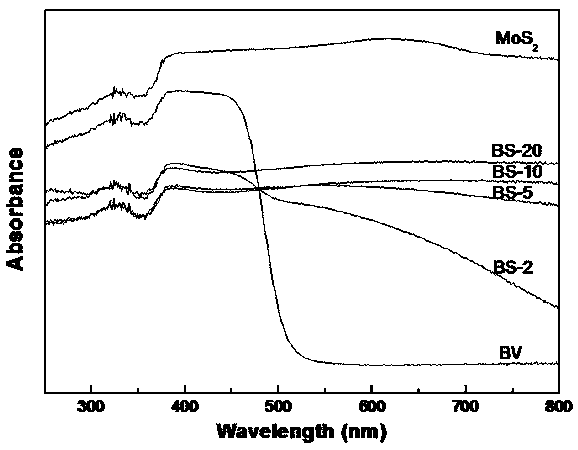

A composite light and catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., to achieve good catalytic performance and efficient degradation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Add 0.7g NH 4 VO 3 and 2.9g Bi(NO 3 ) 3 Add to 50mL nitric acid solution with a molar concentration of 2.0mol / L, and then sonicate for 30min;

[0023] (2) Adjust the pH value of the solution obtained in step (1) to 2 with ammonia water to form a yellow precipitate, and then age it for 2 hours;

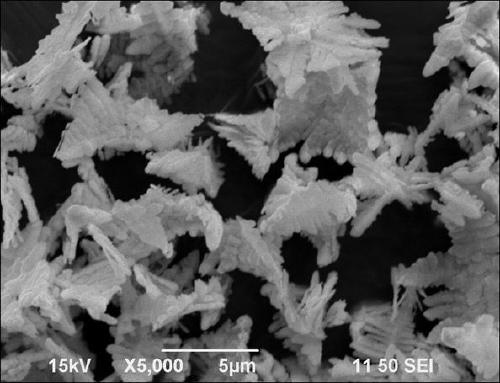

[0024] (3) Transfer the suspension obtained in step (2) to a polytetrafluoroethylene-lined high-pressure hydrothermal reaction kettle for hydrothermal reaction at 200°C for 24 hours, then naturally cool to room temperature and filter, wash with water and ethanol three times respectively , placed in a constant temperature drying oven at 80 ° C for 12 h to obtain butterfly-shaped BiVO 4 Photocatalyst, labeled BV.

[0025] The BiVO prepared in this embodiment 4 The photocatalyst degrades 10mg / L rhodamine B dye wastewater under light, and the degradation rate is 79.0% within 5 hours.

Embodiment 2

[0027] (1) Add 0.7g NH 4 VO 3 and 2.9g Bi(NO 3 ) 3 Add to 50mL nitric acid solution with a molar concentration of 2.0mol / L, and then sonicate for 30min;

[0028] (2) Adjust the pH value of the solution obtained in step (1) to 2 with ammonia water to form a yellow precipitate, and then age it for 2 hours;

[0029] (3) Transfer the suspension obtained in step (2) to a polytetrafluoroethylene-lined high-pressure hydrothermal reaction kettle for hydrothermal reaction at 200°C for 24 hours, then naturally cool to room temperature and filter, wash with water and ethanol three times respectively , placed in a constant temperature drying oven at 80 ° C for 12 h to obtain butterfly-shaped BiVO 4 catalyst of light;

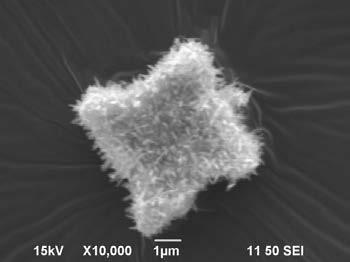

[0030] (4) Add 0.019g (NH 4 ) 6 MoO 7 o 24 4H 2 0 and 0.15g thiourea were added to water and stirred for 30min to obtain a dark green solution;

[0031] (5) Add 0.12g of BiVO prepared in step (3) to the dark green solution obtained in step (4) 4 The photocatalys...

Embodiment 3

[0034] (1) Add 0.7g NH 4 VO 3 and 2.9g Bi(NO 3 ) 3 Add to 50mL nitric acid solution with a molar concentration of 2.0mol / L, and then sonicate for 30min;

[0035] (2) Adjust the pH value of the solution obtained in step (1) to 2 with ammonia water to form a yellow precipitate, and then age it for 2 hours;

[0036] (3) Transfer the suspension obtained in step (2) to a polytetrafluoroethylene-lined high-pressure hydrothermal reaction kettle for hydrothermal reaction at 200°C for 24 hours, then naturally cool to room temperature and filter, wash with water and ethanol three times each , placed in a constant temperature drying oven at 80 ° C for 12 h to obtain butterfly-shaped BiVO 4 catalyst of light;

[0037] (4) Add 0.047g (NH 4 ) 6 MoO 7 o 24 4H 2 O and 0.37g thiourea were added to water and stirred for 30min to obtain a dark green solution;

[0038] (5) Add 0.12g of BiVO prepared in step (3) to the dark green solution obtained in step (4) 4 The photocatalyst was then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com