Cobalt-manganese spinel material as well as preparation method and application thereof

A technology of cobalt-manganese spinel and cobalt acetate, which is applied in chemical instruments and methods, water/sludge/sewage treatment, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of poor catalytic performance and nano-particles Aggregate the problems of high dissolution of metal ions and insufficient utilization of active sites to achieve low production costs, broad economic benefits and application prospects, and low application technology costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Preparation of cobalt manganese spinel material:

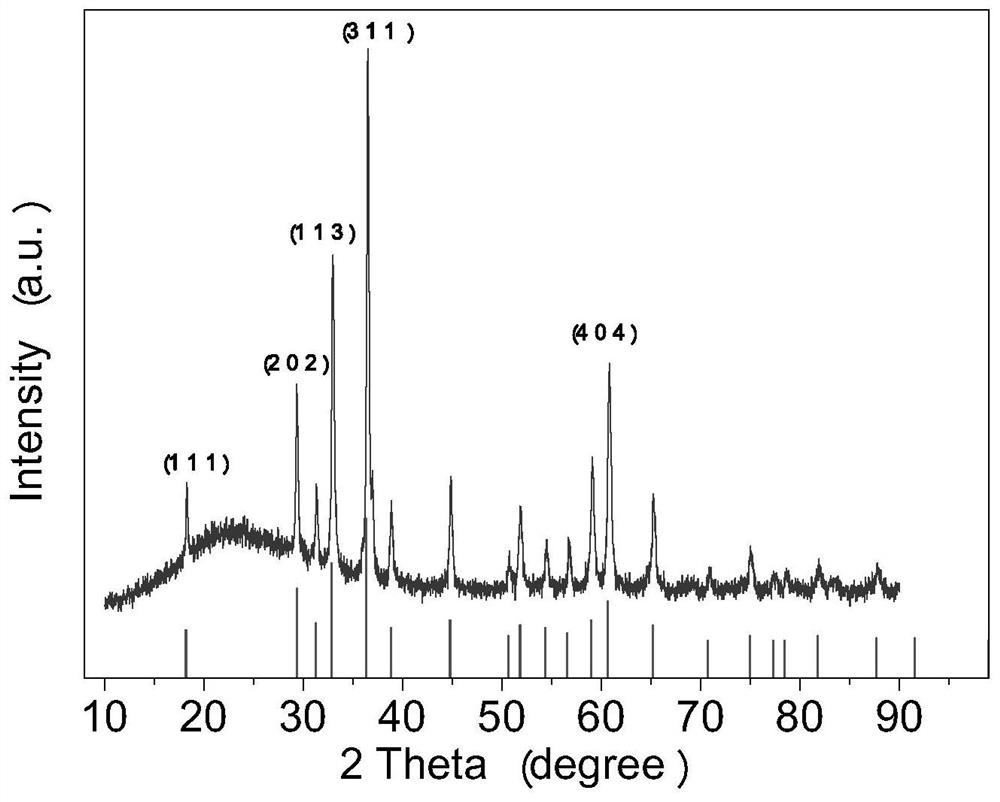

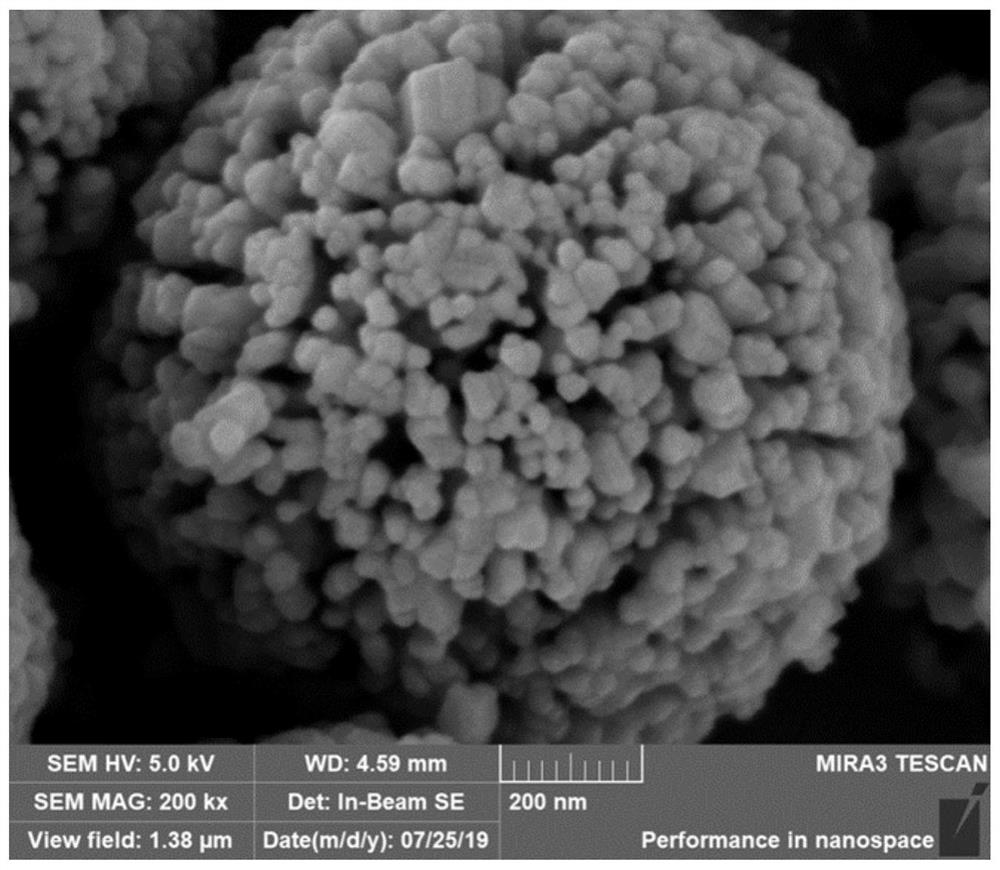

[0030] Measure 0.2491g of Co(OAc) 2 4H 2 O and 0.4902g of Mn(OAc) 2 4H 2 O, dissolved in 40mL of ethylene glycol at room temperature, mixed and stirred until uniformly dissolved; measure 2.3718g of NH 4 HCO 3 , adding the above mixed solution at room temperature to adjust the pH of the solution. After the obtained mixed solution was fully stirred for 30 min, it was transferred to a Teflon-lined stainless steel autoclave with a capacity of 50 mL, and the hydrothermal reaction was carried out at 200 °C for 20 hours. After cooling and centrifuging, a solid precursor was obtained. After washing the obtained precursor, it was transferred to an oven and dried at 60-70° C. for 12 hours. The dried precursor was transferred to a muffle furnace, and it was calcined with a calcination procedure of raising the temperature at 5°C / min to 600°C for 5h, and finally obtained the gray-green (CoMn)(CoMn) 2 o 4 spinel oxide.

[00...

Embodiment 2

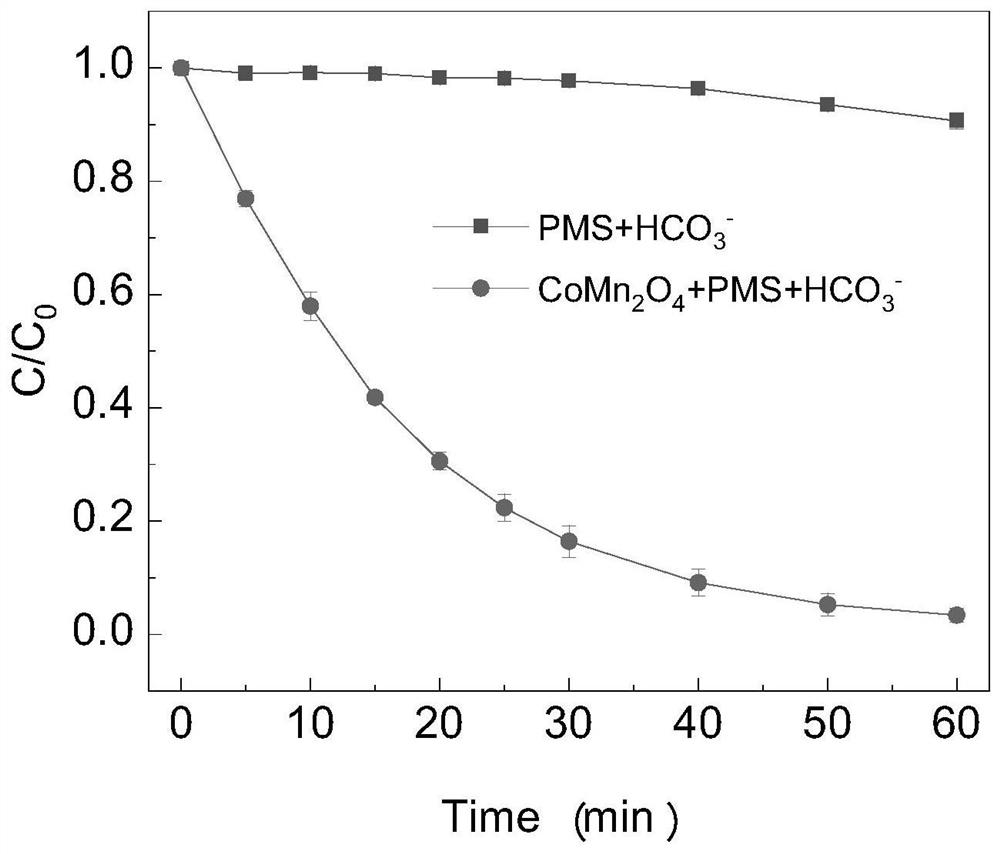

[0034] The cobalt-manganese spinel material prepared in Example 1 was applied to the research on the removal of yellow orange II (AO7).

[0035] Test 1: Take 200mL of Orange II solution with a concentration of 0.070g / L, add cobalt-manganese spinel material in an amount of 0.25g / L, add peroxymonosulfate in an amount of 0.5g / L, and add 0.42g / L Bicarbonate, react at room temperature for 60min.

[0036] Comparative test 1: Take 200 mL of Orange II solution with a concentration of 0.070 g / L, add persulfate in an amount of 0.5 g / L, add 0.42 g / L of bicarbonate, and react at room temperature for 60 min.

[0037] Such as image 3 As shown, from the degradation trend of orange II in the cobalt manganese spinel material / peroxymonosulfate / bicarbonate system, it can be seen that the system has a good removal effect on orange II. After 60 minutes of reaction, the degradation efficiency of Orange II reached 96.6%.

[0038] Such as Figure 4 Shown is the cycle efficiency diagram of cobalt...

Embodiment 3

[0043] The cobalt-manganese spinel material / peroxymonosulfate / bicarbonate system was applied to the research of treating different organic pollutants.

[0044] Test 2: Take 200mL of methyl orange solution with a concentration of 0.065g / L, add cobalt-manganese spinel material in an amount of 0.25g / L, add peroxymonosulfate in an amount of 0.5g / L, and add 0.42g / L Bicarbonate, reacted at room temperature for 60min.

[0045] Test 3: Take 200mL of rhodamine B solution with a concentration of 0.096g / L, add cobalt-manganese spinel material in an amount of 0.25g / L, add peroxymonosulfate in an amount of 0.5g / L, and add 0.42g / L Bicarbonate, reacted at room temperature for 60min.

[0046] Test 4: Take 200mL of reactive brilliant blue solution with a concentration of 0.125g / L, add cobalt manganese spinel material in an amount of 0.25g / L, add peroxymonosulfate in an amount of 0.5g / L, and add 0.42g / L Bicarbonate, reacted at room temperature for 60min.

[0047] Test 5: Take 200mL of phenol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com