Preparation method of catalyst

A technology of catalyst and catalytic activity, applied in the preparation of organic compounds, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of deactivation, carbon deposition, poor stability, etc., and achieve the effect of good catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

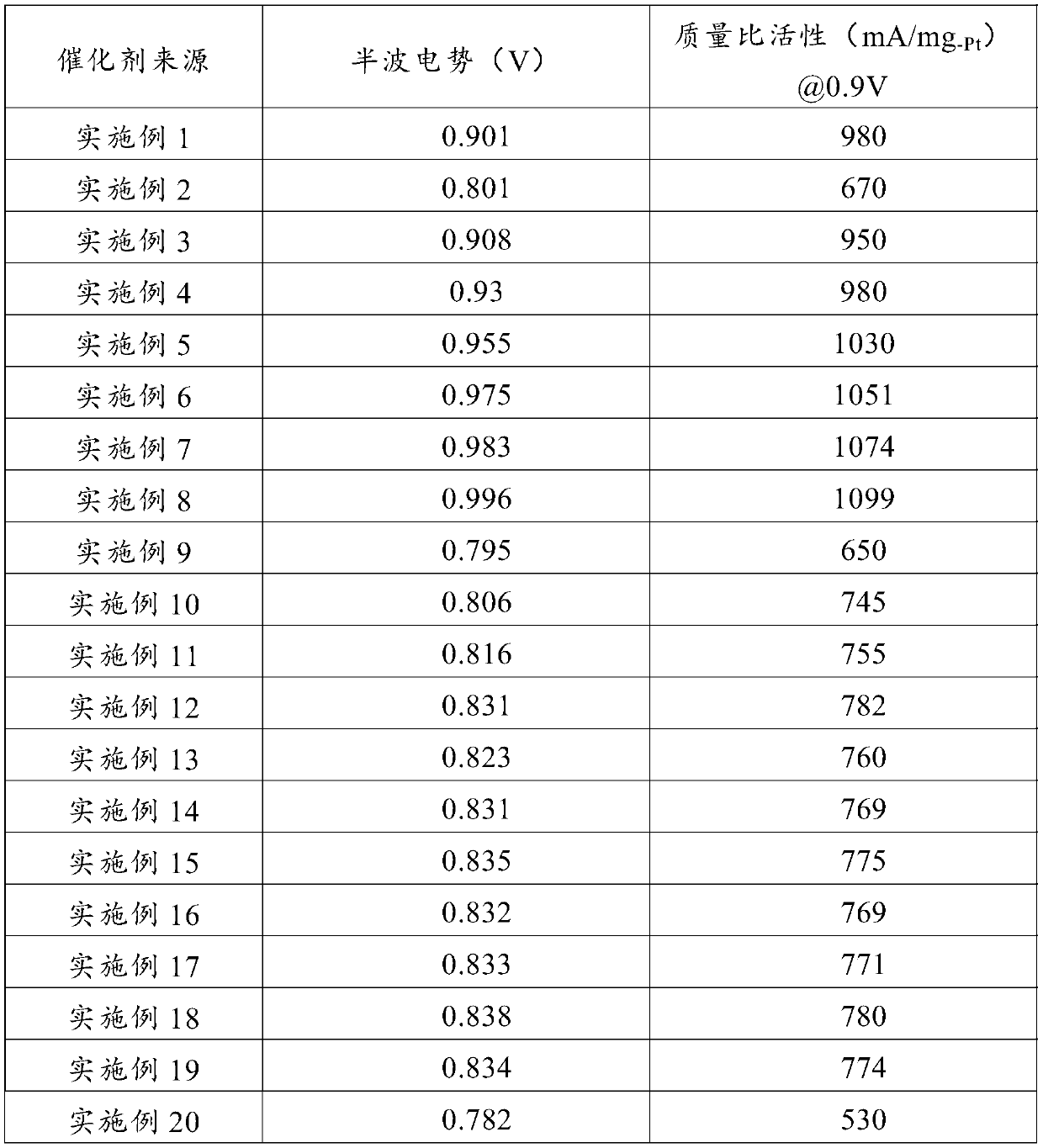

Examples

Embodiment 1

[0032] Embodiment 1: preparation embodiment

[0033] Based on the principle of isotope separation, the natural metal platinum powder is separated by the CAE-1 magnetic separation device of the Institute of Nuclear Technology, China Institute of Atomic Energy (the natural abundance of platinum isotope is: Pt-190 is 0.01%, Pt-192 is 0.79% , Pt-194 is 32.9%, Pt-195 is 33.8%, Pt-196 is 25.3%, Pt-198 is 7.2%), the specific operating conditions are: vaporization temperature 2500 degrees, magnetic field voltage 1000 volts, magnetic separation parameter Pt- 195-98. The separated platinum was collected at the outlet, and detected by ICP-MS, the abundance of Pt-194 was 1.5%, the abundance of Pt-195 was 98%, and the abundance of Pt-196 was 0.5%.

[0034] Add 4 times the mass of conductive graphite as a carbon source to the above separated platinum, and through the hydrothermal method (weigh the salt of the catalytically active substance and dissolve it in deionized water, add the carrie...

Embodiment 2

[0035] Embodiment 2: preparation embodiment

[0036] Based on the principle of isotope separation method, the natural metal platinum powder is separated through the CAE-1 magnetic separation device of the Institute of Nuclear Technology, China Institute of Atomic Energy. The specific operating conditions are: vaporization temperature 2500 degrees, magnetic field voltage 1000 volts, magnetic separation parameters Pt-190 -20. The separated platinum is collected at the outlet, and detected by ICP-MS, the abundance of Pt-190 is 20%, the abundance of Pt-194 is 50%, and the abundance of Pt-198 is 30%.

[0037] 4 times the mass of conductive graphite was added to the platinum after the above separation as a carbon source. After hydrothermal method (weigh the salt of the catalytic active material, dissolve it in deionized water, add the carrier conductive graphite, immerse it for 1h, keep it at 40°C for 2h, 80 drying at ℃ to obtain catalyst precursor. A small amount of urea solution wa...

Embodiment 3

[0038] Example 3: Preparation Example

[0039] Based on the principle of isotope separation method, the natural metal platinum powder is separated by the CAE-1 magnetic separation device of the Institute of Nuclear Technology, China Institute of Atomic Energy. -100. The separated platinum was collected at the discharge port, and detected by ICP-MS, the abundance of Pt-190 was 100%.

[0040] Add 4 times the mass of conductive graphite as a carbon source to the platinum after the above separation to prepare a Pt / C catalyst with a mass fraction of Pt of 20%. The specific preparation method is as follows:

[0041] Preparation of metal Pt into H 2 PtCl 6 solution, prepared as 1 mol / L of H 2 PtCl 6 . Add conductive graphite, stir evenly, use NaOH as a precipitant, adjust the pH to 7.5, and obtain a black precipitate by centrifugal washing, which is calcined at 500°C under hydrogen to obtain a catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com