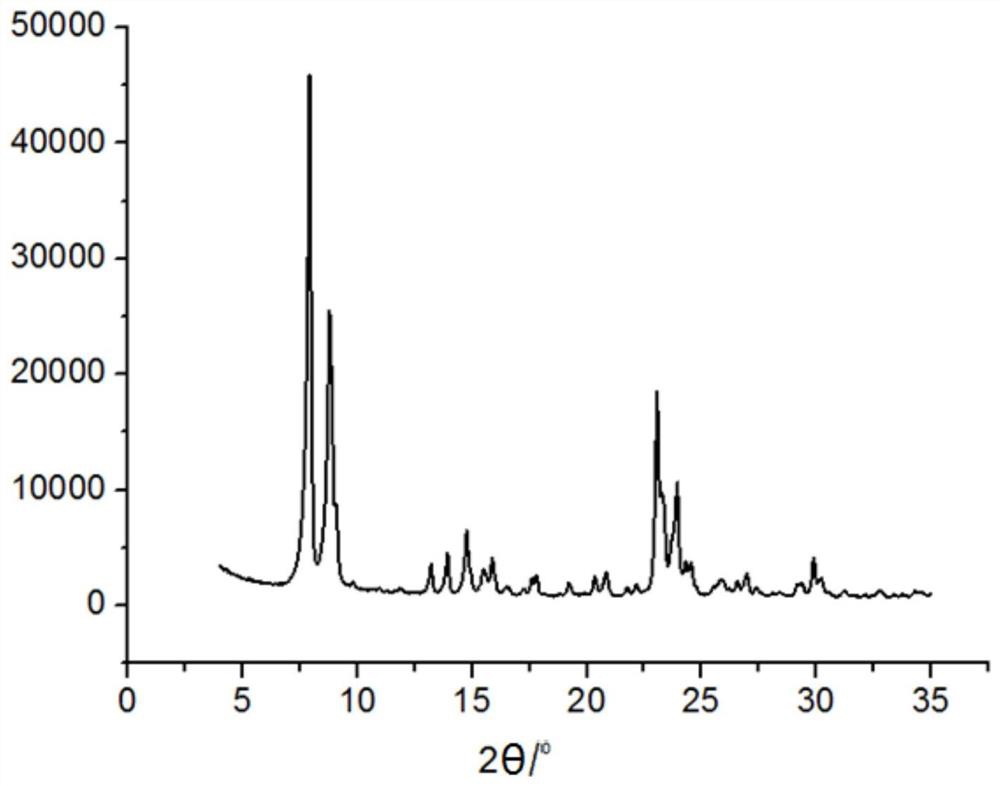

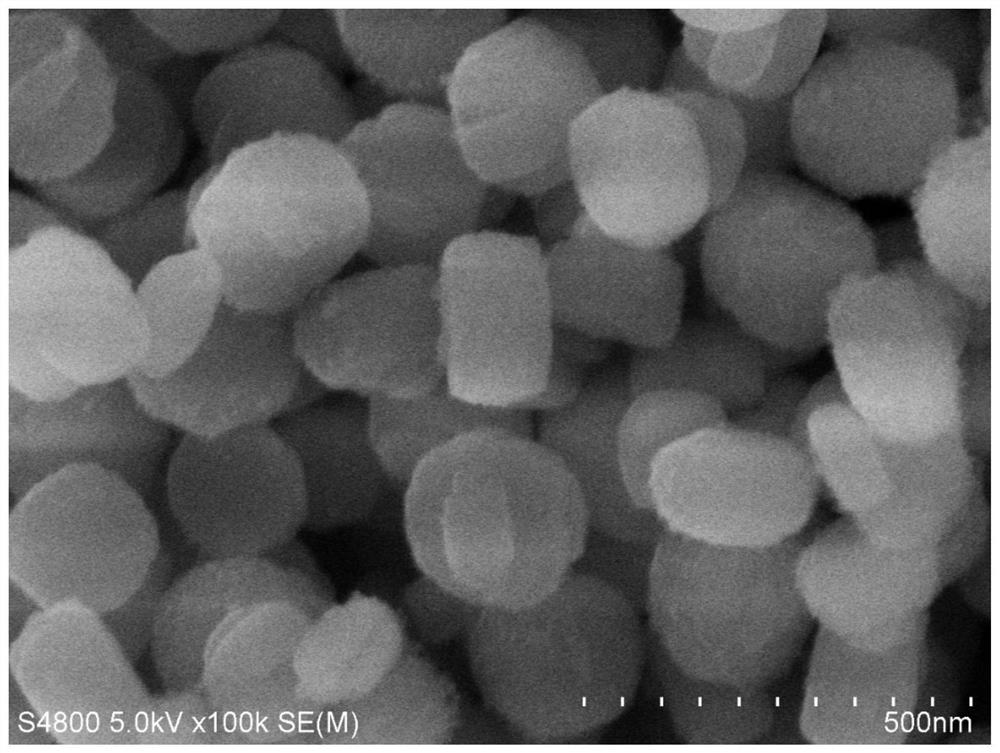

MFI topological structure silicon molecular sieve as well as preparation method and application thereof

A technology of silicon molecular sieve and molecular sieve, which is applied in the field of MFI topological structure silicon molecular sieve and its preparation, can solve the problems of high content of amorphous silicon oxide, poor relative crystallinity, large crystal particles, etc., achieve good catalytic performance and improve conversion rate , Improve the effect of economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

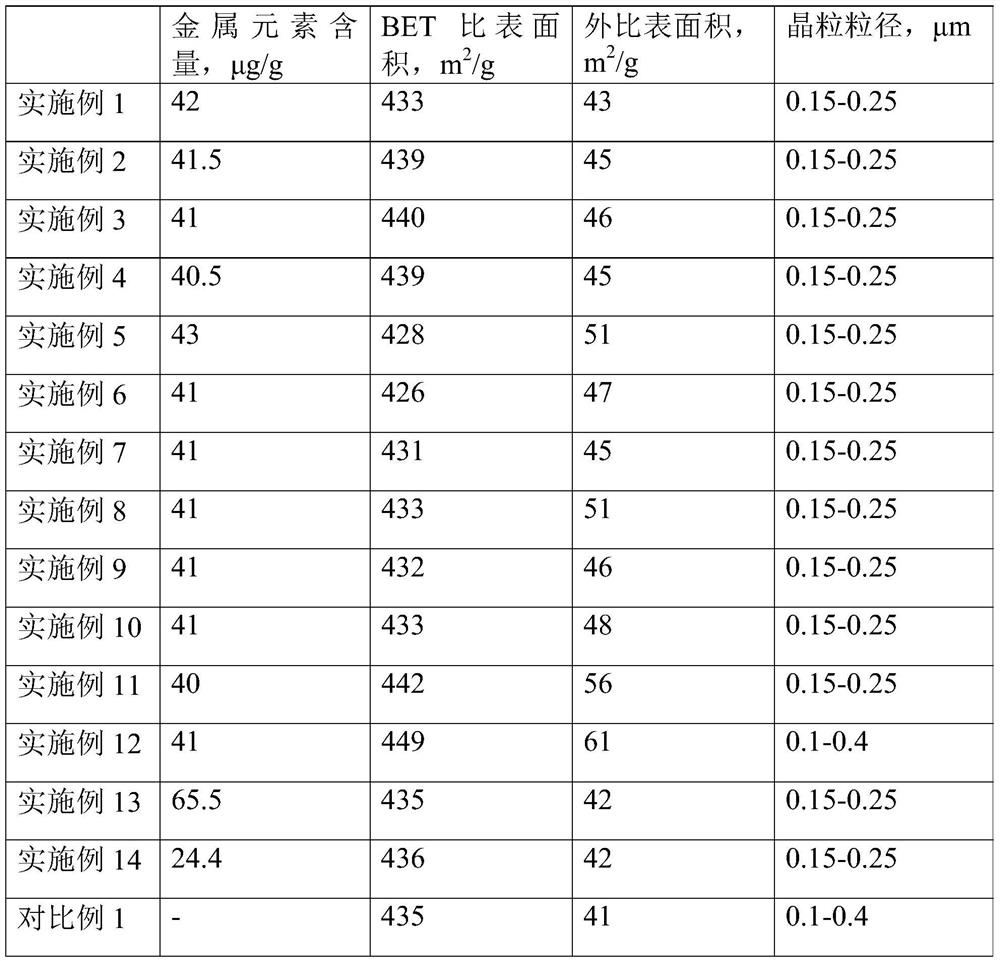

Examples

preparation example Construction

[0037] The second aspect of the present invention provides a method for preparing a silicon molecular sieve with an MFI topological structure, the method comprising:

[0038] (1) Mix silicon source, organic amine, organic template, metal source, organic alcohol and water to obtain a colloidal mixture, wherein the molar ratio of silicon source, organic amine, organic template, organic alcohol and water is 1:(0.05 -0.5): (0.05-0.5): (4-20): (5-100), the mass ratio of the silicon source to the metal source is (10000-200000): 1, the silicon source is SiO 2 Calculated, the metal source is calculated as a metal element;

[0039] (2) The colloidal mixture is subjected to two-stage variable temperature alcohol-hydrothermal system crystallization, and the conditions for the two-stage variable temperature alcohol-hydrothermal system crystallization include: crystallization at 40-70°C for 0.5-5 days, and then Crystallization at 80-130°C for 0.5-5 days;

[0040] (3) filtering, drying an...

Embodiment approach

[0053] According to a specific embodiment of the present invention, the first mixing is carried out under stirring conditions, and there is no special limitation on the stirring time, as long as the ethanol, the organic amine and the organic template are mixed uniformly. Specifically, the method may further include, after adding the metal source and water, stirring, and then adding the ethyl orthosilicate.

specific Embodiment approach

[0054] According to a specific embodiment of the present invention, the method may further include: after adding tetraethyl orthosilicate, stirring to obtain the colloidal mixture. In the present invention, there is no special limitation on the stirring conditions, as long as the colloidal mixture can be obtained. For example, it can be stirred at normal temperature (25°C) for 2-6 hours.

[0055] According to another preferred embodiment of the present invention, the silicon source is methyl orthosilicate, and the organic alcohol is methanol. The inventors of the present invention found in the research process that the combined use of methyl orthosilicate as a silicon source and methanol as an organic alcohol is more conducive to further improving the catalytic performance of the prepared molecular sieve. Preferably, the mixing in step (1) includes: mixing methanol, organic amine and organic template for the second time, then adding metal source and water, and then adding met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com