Method for treating wastewater by using steelmaking converter dust sludge as heterogeneous Fenton catalyst

A technology for heterogeneous Fenton and steel-making converters, applied in chemical instruments and methods, special compound water treatment, oxidized water/sewage treatment, etc. Wide range of process parameters, simple method and good catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

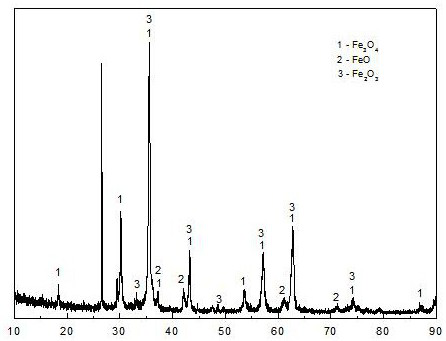

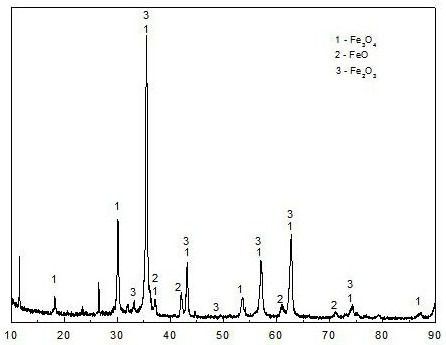

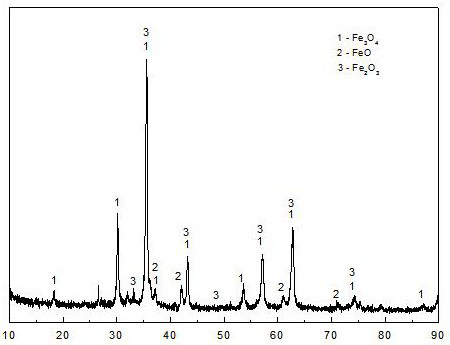

Image

Examples

Embodiment 1

[0028] Obtain dust from converter steelmaking flue gas purification from a certain iron and steel plant, wash it with 1:10 water at 50°C, wash twice for 0.5h. Under stirring conditions, add 0.5g / L of pre-washed converter dust into 50mg / L methylene blue solution, add 0.35ml / L hydrogen peroxide, adjust the pH value to 4.5, and react under visible light for 3h. After the reaction, adjust the pH to 8.5, settle for 0.5h, and the supernatant is recovered by magnetic separation and then effluents. The decolorization rate of methylene blue reaches 99.1%. The result is as Figure 6 , Methylene blue has a characteristic absorption peak at 664nm, and the characteristic absorption peak disappears after 3 hours of reaction.

Embodiment 2

[0030] Under the condition of stirring, add the pretreated dust sludge obtained in Example 1 into the methylene blue solution of 100mg / L at 3.5 g / L, add hydrogen peroxide 1.2ml / L, adjust the pH value to 4, and Reaction 1.8h. After the reaction, adjust the pH to 7.5, settling for 2 hours, and the supernatant was recovered by magnetic separation, and the water was discharged. The decolorization rate of methylene blue reached 98.75%. Ultraviolet light irradiation is beneficial to increase the generation rate of hydroxyl radicals, improve the catalytic efficiency and shorten the reaction time.

Embodiment 3

[0032] Obtain converter steelmaking flue gas purification dust collection mud from a steel plant, wash it with 1:20 water at 90°C, and wash once for 2 hours. Under stirring conditions, add 3.8 g / L of washed dust into 65 mg / L of methyl orange solution, add 0.8 ml / L of hydrogen peroxide, adjust the pH value to 2.8, and react under visible light for 3 hours. Adjust the pH=7.8 at the end of the reaction, settling for 3 hours, the supernatant was recovered by magnetic separation, and the water was discharged, and the dust was collected by settling and magnetic separation. Under this condition, the first reaction is an activation process. After activation, the collected dust and sludge are treated twice under the same conditions. The decolorization effect is as follows: Figure 7 , the decolorization rate has reached 98.87% and 98.21% at 2.5h for the second and third times, indicating that after activation, the catalytic decolorization efficiency of converter dust and sludge has bee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com