A kind of so42-/tio2-c nanotube, preparation method and application thereof

A nanotube, tio2-c technology, applied in the field of nanotubes, can solve the problems of sulfate radical loss, activity attenuation, etc., and achieve the effects of not easy coking, active and simple and feasible preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

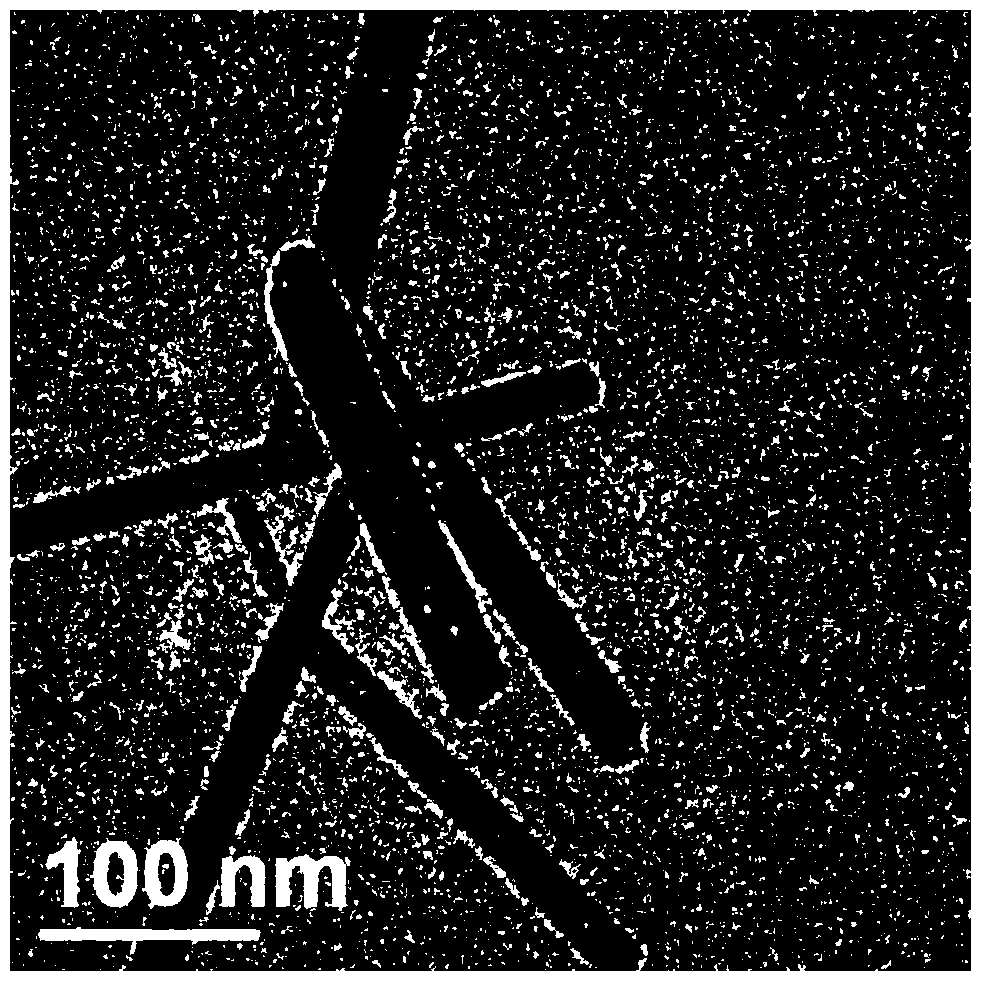

Image

Examples

Embodiment 1

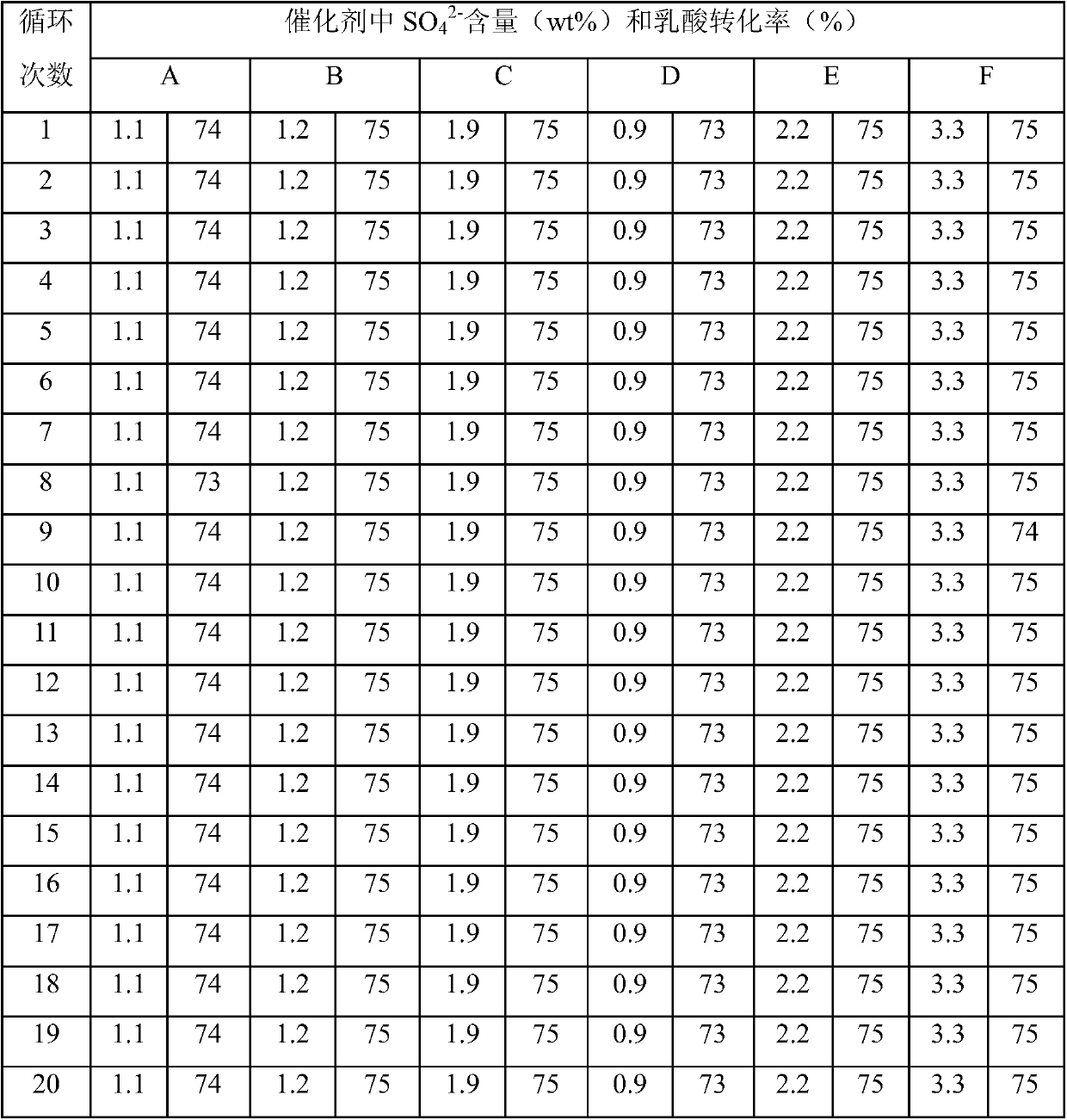

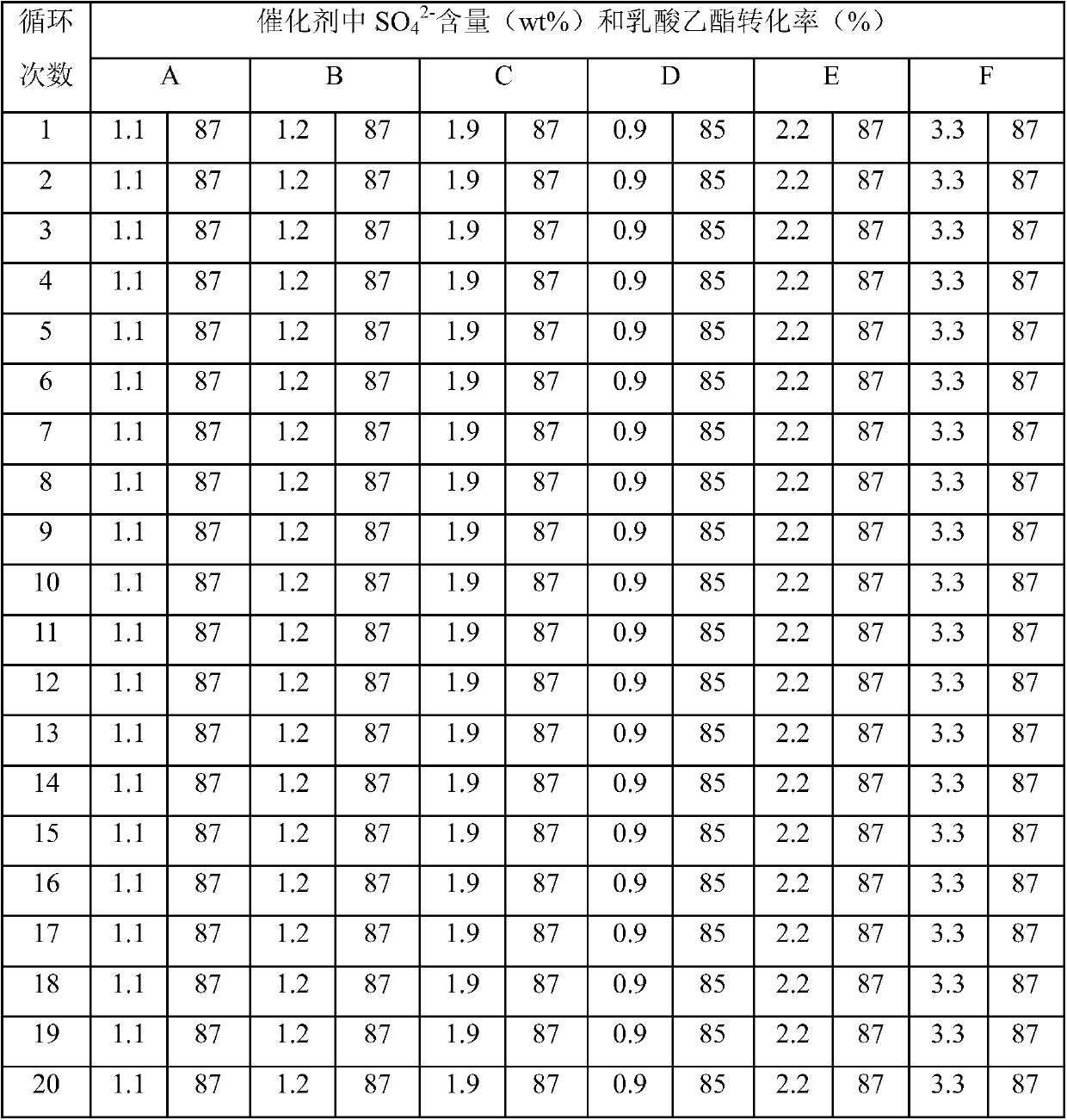

[0034] TiO 2 Add 100 parts of powder to 500 parts of NaOH aqueous solution with a mass fraction of 10%, hydrothermally react at 120°C for 24 hours to obtain a hydrothermal product, filter and wash the product after hydrothermal reaction, and dry at 60°C for 5 hours to obtain a solid containing titanic acid . Take 100 parts of dried solids and mix them with 60 parts of glucose aqueous solution, stir, dry at 40°C, and dry under N 2 Calcined at 400°C in a mixed atmosphere with n-propanol to obtain TiO 2 -C nanotubes. will be on TiO 2 - 10 parts of C nanotubes are dispersed in 0.5 parts of 35% sulfuric acid aqueous solution, stirred, dried at 50°C, and roasted at 400°C to obtain SO 4 2- / TiO 2 -C nanotube A, measured in which TiO 2 The mass percentage is 95%, the carbon mass percentage is 3.9%, the sulfate radical mass percentage is 1.1%, and the carbon 98% is covered in TiO 2 The inner surface of the nanotube has an average diameter of 9.5nm.

Embodiment 2

[0036] TiO 2 Add 100 parts of powder to 400 parts of KOH aqueous solution with a mass fraction of 20%, hydrothermally react at 130°C for 48 hours to obtain a hydrothermal product, filter and wash the product after hydrothermal reaction, and dry at 70°C for 5 hours to obtain a solid containing titanic acid . Take 100 parts of dried solid and 80 parts of water-methanol solution of phenolic resin, mix, stir, dry at 50°C, and dry in N 2 Calcined at 420°C in a mixed atmosphere with n-butanol to obtain TiO 2 -C nanotubes. will be on TiO 2 - Disperse 10 parts of C nanotubes in 1 part of 35% sulfuric acid aqueous solution, stir, dry at 50°C, and roast at 450°C to obtain SO 4 2- / TiO 2 -C nanotube B, measured in which TiO 2 The mass percentage is 93%, the carbon mass percentage is 5.8%, the sulfate radical mass percentage is 1.2%, and the carbon 97.5% is covered in TiO 2 The inner surface of the nanotube has an average diameter of 9.0nm.

Embodiment 3

[0038] TiO 2 Add 100 parts of powder to 400 parts of KOH aqueous solution with a mass fraction of 20%, hydrothermally react at 100°C for 48 hours to obtain a hydrothermal product, filter and wash the product after hydrothermal reaction, and dry at 65°C for 5 hours to obtain a solid containing titanic acid . Take 100 parts of the dried solid and mix 90 parts of furfural in n-butanol solution, stir, dry at 50°C, and dry under N 2 Calcined at 380°C in a mixed atmosphere with isobutanol to obtain TiO 2 -C nanotubes. will be on TiO 2 - Disperse 10 parts of C nanotubes in 1 part of 50% sulfuric acid aqueous solution, stir, dry at 60°C, and roast at 500°C to obtain SO 4 2- / TiO 2 -C nanotube C, measured in which TiO 2 The mass percentage is 90%, the carbon mass percentage is 8.1%, the sulfate radical mass percentage is 1.9%, and the carbon 96.5% is covered in TiO 2 The inner surface of the nanotube has an average diameter of 6.3nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com