Method for inducing and synthesis gamma-Ca(BH4)2 through mechanical force

A technology of hydrogen storage material and mechanical force, applied in chemical instruments and methods, borane/diborane hydride, hydrogen and other directions, can solve problems such as difficult synthesis, and achieve low production cost, high efficiency, and easy reaction process. control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] In a glove box filled with argon, with CaCl 2 and NaBH 4 Weigh 10g CaCl with a molar ratio of 1:2 2 and NaBH 4 , stirred magnetically under 200ml THF solvent for 2h, the resulting solution was transferred to a stainless steel reactor, kept at 90°C for 5h, and after filtration, the resulting clear solution was placed in a dynamic vacuum for 10 -3 bar, temperature 55 ° C conditions to remove the solvent treatment, the reaction precursor Ca(BH 4 ) 2 • THF.

[0033] Weigh 5g homemade Ca (BH 4 ) 2 THF precursor, put into the ball mill tank (stainless steel tank with on-off valve) with grinding balls, at 5bar H 2 Under the condition of atmosphere and 40°C, the obtained precursor was subjected to high-energy ball milling with a ball-to-material ratio of 80:1, a ball milling speed of 300 rpm, and a ball milling time of 12 hours. Ball milled product at 150°C, dynamic vacuum 10 -6 Under the condition of bar, heat treatment for 6h, the preparation of γ-Ca(BH 4 ) 2 .

...

Embodiment 2

[0036] In a glove box filled with argon, with CaCl 2 and NaBH 4 Weigh 10g CaCl with a molar ratio of 1:2 2 and NaBH 4 , stirred magnetically under 200ml THF solvent for 3h, the resulting solution was transferred to a stainless steel reactor, kept at 100°C for 3h, and after filtration, the resulting clear solution was placed in a dynamic vacuum for 10 -4 bar, temperature of 50 ° C conditions to remove the solvent treatment, the reaction precursor Ca(BH 4 ) 2 • THF.

[0037] Weigh 5g homemade Ca (BH 4 ) 2 THF precursors, put into a ball mill jar with balls at 2 bar N 2 Under the condition of atmosphere and 40°C, the obtained precursor was subjected to high-energy ball milling with a ball-to-material ratio of 100:1, a ball milling speed of 250 rpm, and ball milling times of 12h, 16h, and 20h, respectively. Ball milled product at 140°C, dynamic vacuum 10 -3 Under the condition of bar, heat treatment for 10h, Ca(BH 4 ) 2 .

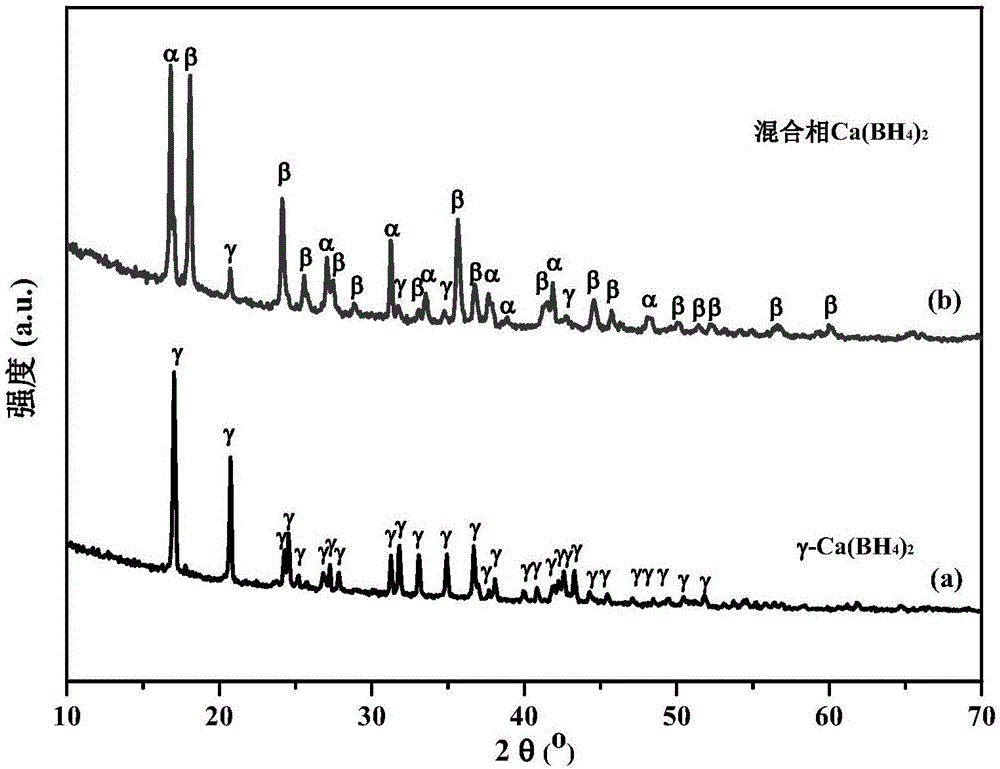

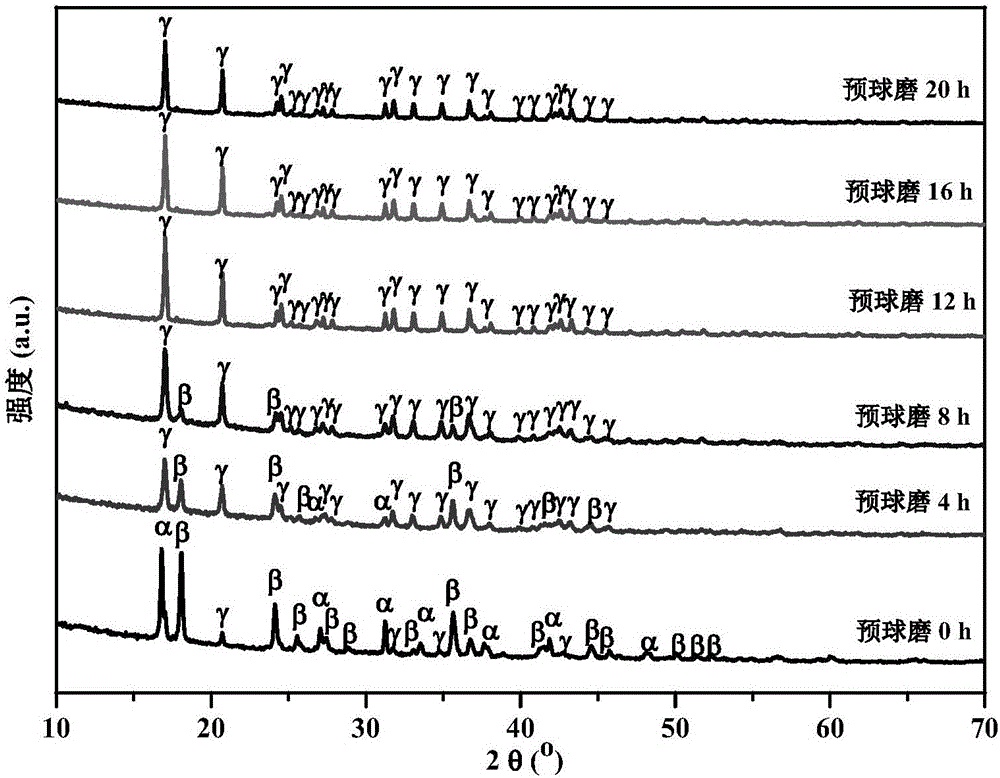

[0038] figure 2 It is the XRD pattern of th...

Embodiment 3

[0043] In a glove box filled with argon, with CaCl 2 and NaBH 4 Weigh 10g CaCl with a molar ratio of 1:2 2 and NaBH 4 , stirred magnetically under 200ml THF solvent for 3h, the resulting solution was transferred to a stainless steel reactor, kept at 80°C for 6h, and after filtration, the resulting clear solution was placed in a dynamic vacuum for 10 -5 bar, temperature 45 ° C conditions to remove the solvent treatment, the reaction precursor Ca(BH 4 ) 2 •THF.

[0044] Weigh 5g homemade Ca (BH 4 ) 2 Put the THF precursor into a ball milling tank with balls, and carry out high-energy ball milling on the obtained precursor under the condition of 2bar Ar atmosphere and 50°C, the ball-to-material ratio is 80:1, the ball milling speed is 300rpm, 12h, 16h and 20h respectively. Ball milled product at 100°C, dynamic vacuum 10 -4 Under the condition of bar, heat treatment for 6 hours, Ca(BH 4 ) 2 .

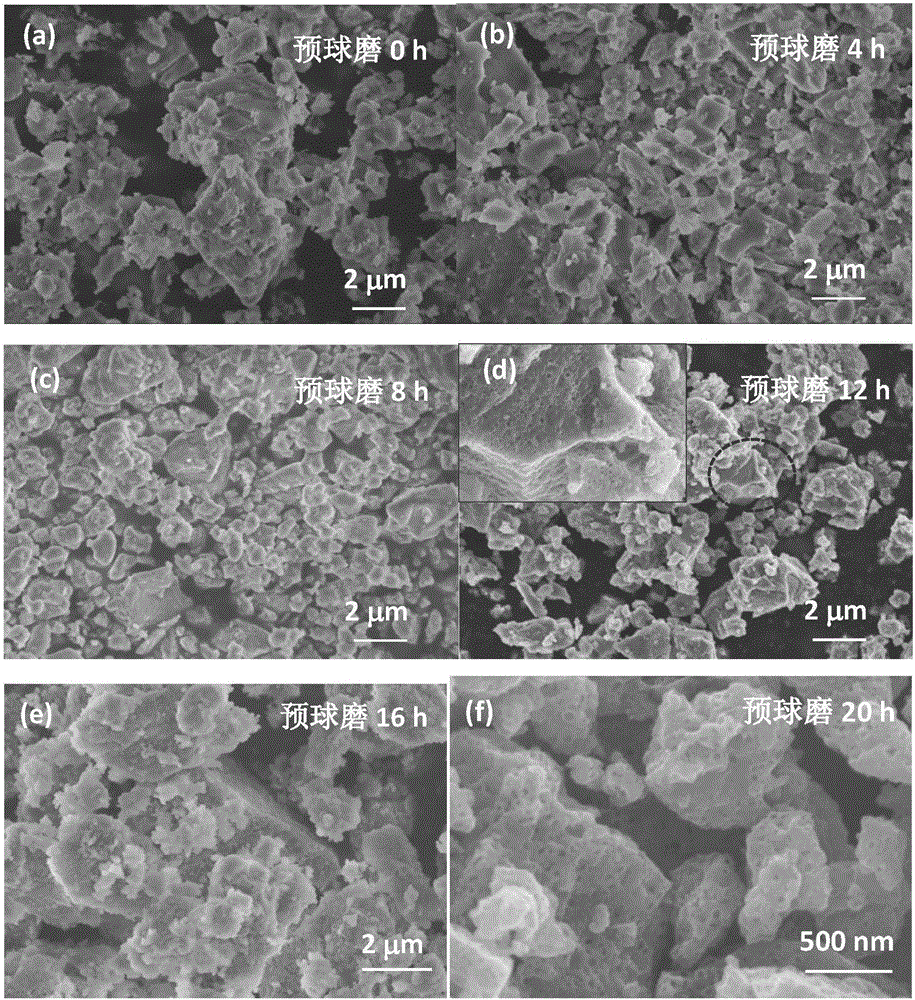

[0045] image 3 It is a scanning electron microscope picture of the produc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com