Critical or supercritical solar water and power coproduction device

A supercritical and solar energy technology, which is applied in the directions of solar thermal power generation, mechanical power generation by solar energy, general water supply saving, etc., can solve the problems of high energy consumption of seawater desalination and low conversion efficiency of solar energy "light-to-electricity", so as to weaken the natural Effects of convective loss, increased water production, and reduced heat leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further elaborated below in conjunction with specific illustrations and examples.

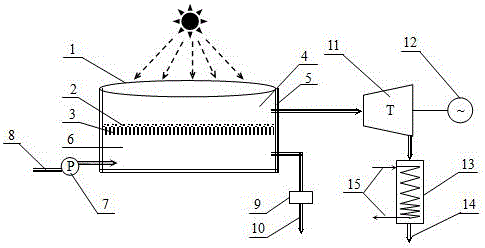

[0025] The specific implementation of a critical or supercritical solar hydropower cogeneration device of the present invention will be described in detail below in conjunction with the accompanying drawings. like figure 1 As shown, it is a schematic structural diagram of a critical or supercritical solar hydropower cogeneration device of the present invention, including a seawater evaporator, the top of the seawater evaporator is a light concentrating device, and there is a horizontal hydrophilic porous medium layer in the middle, and the seawater The evaporator is divided into upper and lower parts, the upper part is a steam chamber, and the lower part is a supplementary chamber. The surface of the hydrophilic porous medium layer has a solar absorbing coating, and the solar absorbing coating will not block the pores of the hydrophilic porous medium layer....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com