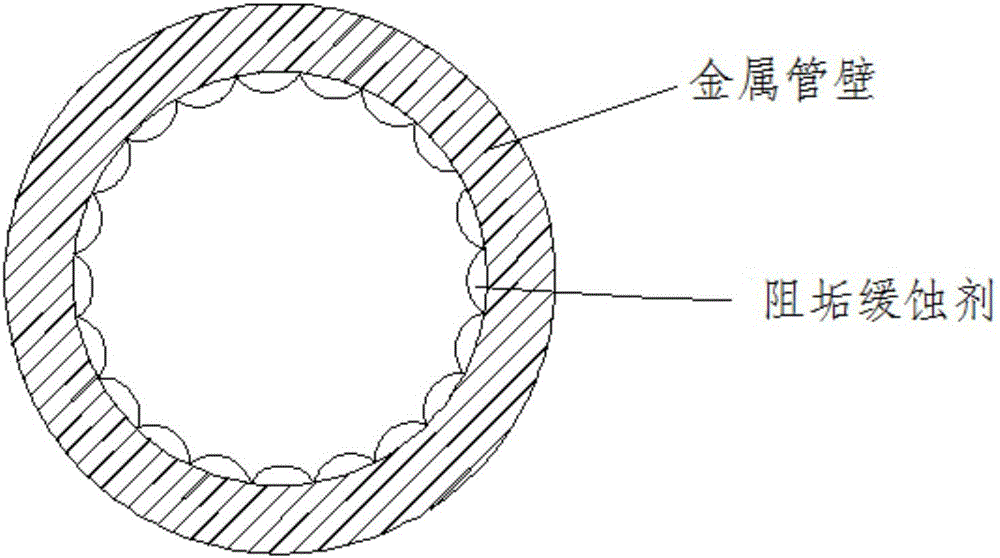

Scaling corrosion inhibitor and preparation method thereof

A technology of scale and corrosion inhibitor, foam discharge agent, applied in chemical instruments and methods, descaling and water softening, special treatment targets, etc. Excellent scale and corrosion inhibition effect, wide application range and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A kind of antiscaling and corrosion inhibitor, by 2-phosphonobutane-1,2,4-tricarboxylic acid (PBTCA) aqueous solution, 2-hydroxyphosphonoacetic acid (HPAA) aqueous solution, acrylic acid / acrylate copolymer (HB- 901) aqueous solution, polyaspartic acid (PASP) aqueous solution and foaming agent are prepared;

[0051] Among them, according to the ratio of substances, 2-phosphonobutane-1,2,4-tricarboxylic acid (PBTCA): 2-hydroxyphosphonoacetic acid (HPAA): acrylic acid / acrylate copolymer (HB-901): Polyaspartic acid (PASP):foaming agent=2:2:5:10:5;

[0052] 2-Phosphonobutane-1,2,4-tricarboxylic acid (PBTCA), 2-hydroxyphosphonoacetic acid (HPAA), acrylic acid / acrylate copolymer (HB-901), and polyaspartic acid (PASP) Before use, it is prepared into an aqueous solution;

[0053] Among them, the concentration of 2-phosphonobutane-1,2,4-tricarboxylic acid (PBTCA) aqueous solution is 30 mg / L; the concentration of 2-hydroxyphosphonoacetic acid (HPAA) aqueous solution is 20 mg / L; ...

Embodiment 2

[0073] A kind of antiscaling and corrosion inhibitor, by 2-phosphonobutane-1,2,4-tricarboxylic acid (PBTCA) aqueous solution, 2-hydroxyphosphonoacetic acid (HPAA) aqueous solution, acrylic acid / acrylate copolymer (HB- 901) aqueous solution, polyaspartic acid (PASP) aqueous solution and foaming agent are prepared;

[0074] Among them, according to the ratio of substances, 2-phosphonobutane-1,2,4-tricarboxylic acid (PBTCA): 2-hydroxyphosphonoacetic acid (HPAA): acrylic acid / acrylate copolymer (HB-901): Polyaspartic acid (PASP):foaming agent=3:3:8:15:8;

[0075] 2-Phosphonobutane-1,2,4-tricarboxylic acid (PBTCA), 2-hydroxyphosphonoacetic acid (HPAA), acrylic acid / acrylate copolymer (HB-901), and polyaspartic acid (PASP) Before use, it is prepared into an aqueous solution;

[0076] Among them, the concentration of 2-phosphonobutane-1,2,4-tricarboxylic acid (PBTCA) aqueous solution is 40 mg / L; the concentration of 2-hydroxyphosphonoacetic acid (HPAA) aqueous solution is 30 mg / L; ...

Embodiment 3

[0096] A kind of antiscaling and corrosion inhibitor, by 2-phosphonobutane-1,2,4-tricarboxylic acid (PBTCA) aqueous solution, 2-hydroxyphosphonoacetic acid (HPAA) aqueous solution, acrylic acid / acrylate copolymer (HB- 901) aqueous solution, polyaspartic acid (PASP) aqueous solution and foaming agent are prepared;

[0097] Among them, according to the ratio of substances, 2-phosphonobutane-1,2,4-tricarboxylic acid (PBTCA): 2-hydroxyphosphonoacetic acid (HPAA): acrylic acid / acrylate copolymer (HB-901): Polyaspartic acid (PASP):foaming agent=2:3:8:12:8;

[0098] The 2-phosphonobutane-1,2,4-tricarboxylic acid (PBTCA), 2-hydroxyphosphonoacetic acid (HPAA), acrylic acid / acrylate copolymer (HB-901) and polyaspartic acid (PASP) was prepared into an aqueous solution before use;

[0099] Among them, the concentration of 2-phosphonobutane-1,2,4-tricarboxylic acid (PBTCA) aqueous solution is 30 mg / L; the concentration of 2-hydroxyphosphonoacetic acid (HPAA) aqueous solution is 20 mg / L; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com