Additive for preparing powdery polycarboxylate superplasticizer and application method thereof

An additive, polycarboxylic acid technology, applied in the field of building materials, can solve the problems of complex manufacturing process, difficult control of reaction heat, poor effect of water reducing agent, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

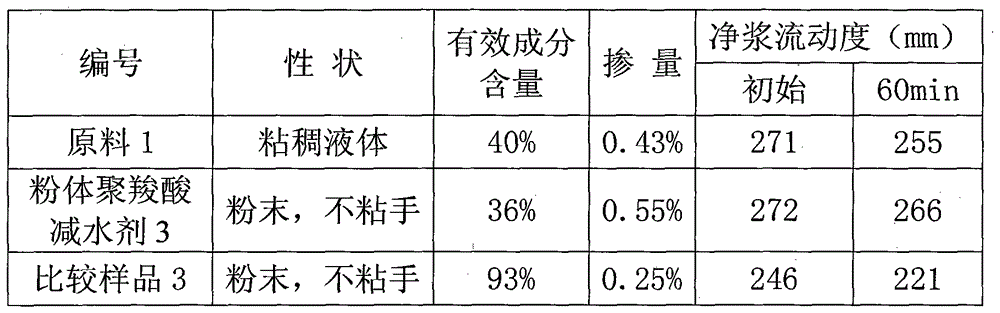

[0018] Embodiment 1: Additive formula 1 and its use method and effect

[0019] 1. Formula 1:

[0020] This additive is composed of A component and B component, A component: 10 parts of calcium oxide, 10 parts of magnesium oxide, 20 parts of calcium aluminate, 10 parts of magnesium chloride; B component: 5 parts of sodium bicarbonate, 50 parts of calcium sulfate , 5 parts of aluminum sulfate.

[0021] 2. How to use:

[0022] a. The polycarboxylate superplasticizer aqueous solution (the esterification product of polyethylene glycol monomethyl ether (MPEG) and maleic anhydride) with a solid content of 40% by mass is a macromonomer, and acrylic acid is a small monomer. The weight average molecular weight is about 12600) (raw material 1) 350 parts into the container, then add 100 parts of the A component of the additive, and stir for 20 minutes, the aqueous solution of polycarboxylate superplasticizer gradually becomes viscous and stable the slurry;

[0023] b. Add 30 parts of ...

Embodiment 2

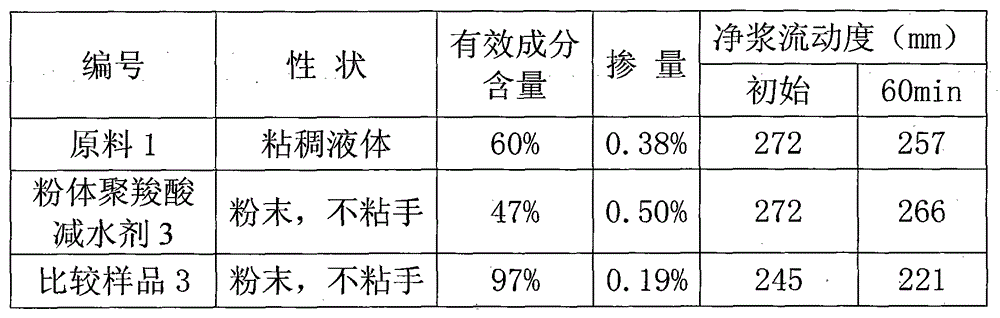

[0029] Embodiment 2: Additive formula 2 and its use method and effect

[0030] 1. Recipe 2

[0031] This additive is composed of A component and B component, A component: 50 parts of calcium oxide, 40 parts of magnesium oxide, 50 parts of calcium aluminate, 30 parts of magnesium chloride; B component: 15 parts of sodium bicarbonate, 85 parts of calcium sulfate , 15 parts of aluminum sulfate.

[0032] 2. How to use:

[0033] a. Polycarboxylate superplasticizer aqueous solution (methallyl polyether (TPEG) is a large monomer, methacrylic acid and maleic anhydride are small monomers) copolymerized with a solid content of 60% by mass, and the weight average Add 300 parts of molecular weight to about 17200) (raw material 2) into the container, then add 90 parts of component A of the additive, and stir for 60 minutes, the aqueous solution of polycarboxylate superplasticizer gradually becomes a viscous, stable slurry body;

[0034] b. Add 10 parts of component B of the additive to...

Embodiment 3

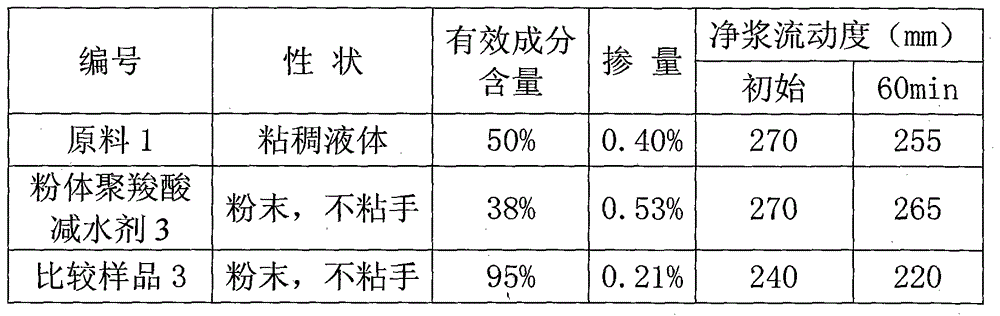

[0040] Embodiment 3: Additive formula 3 and its use method and effect

[0041] 1. Recipe 3

[0042] This additive is composed of A component and B component, A component: 20 parts of calcium oxide, 30 parts of magnesium oxide, 40 parts of calcium aluminate, 20 parts of magnesium chloride; B component: 10 parts of sodium bicarbonate, 70 parts of calcium sulfate , 10 parts of aluminum sulfate.

[0043] 2. How to use:

[0044] a. Polycarboxylate superplasticizer aqueous solution with a solid content of 50% by mass (allyl polyether (APEG) is a large monomer, acrylic acid is a small monomer, and the weight average molecular weight is about 14800) (raw material 3) Add 320 parts into the container, then add 95 parts of component A of the additive, and stir for 40 minutes, the aqueous solution of the polycarboxylate superplasticizer gradually becomes a viscous, stable slurry;

[0045] b. Add 20 parts of component B of the additive to the slurry, and stir for 35 minutes to dehydrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com