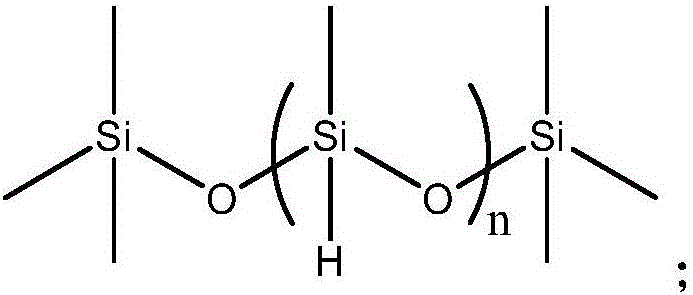

Low molecular siloxane and preparation method thereof as well as used catalyst and preparation method thereof

A molecular siloxane and catalyst technology, applied in metal/metal oxide/metal hydroxide catalysts, heterogeneous catalyst chemical elements, physical/chemical process catalysts, etc., can solve the problem of wide molecular weight distribution of reaction products and difficult products. Separation, waste liquid polluting the environment, etc., to achieve the effects of high practical value, multiple reuse times, and strong reaction selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

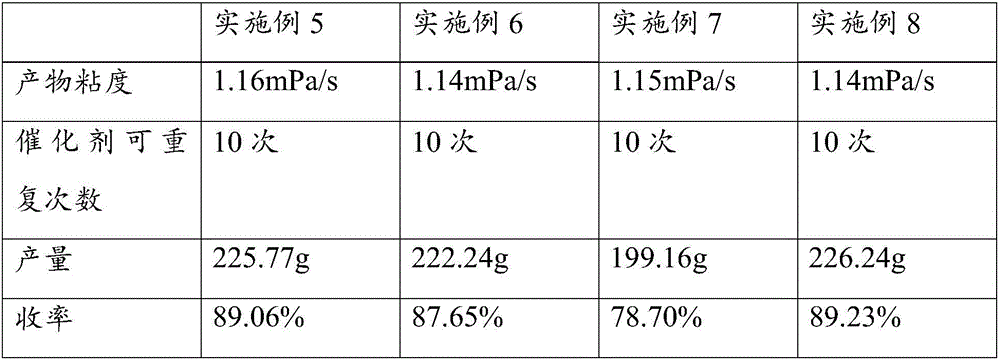

Examples

Embodiment 1

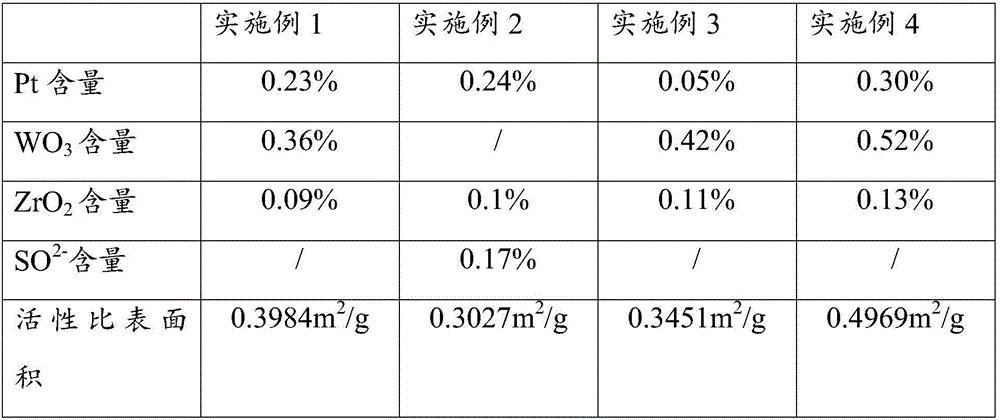

[0035] Preparation of catalyst

[0036] The first step: Slowly drop 500ml, 0.5mol / L ammonia water into 100ml, 0.5mol / L Zr(NO 3 ) 4 In the aqueous solution, to pH = 9-10, zirconium hydroxide precipitates, and then reflux in an oil bath at 100°C for 24 hours. The precipitate was repeatedly washed with deionized water and filtered to pH = 7, and the filter cake was dried at 105 °C to obtain 5.37 g of ZrO 2 , take 1gZrO 2 Soak in 16.5ml, 1mol / LH 8 N 2 o 4 In the W solution, add 10L, 2.0mol / LAl(NO 3 ) 3 aqueous solution, the mixture was refluxed at 120°C for 18 hours, then dried at 110°C for 10 hours, and calcined for 3 hours to obtain 1020 g of crude product.

[0037] The second step: take 20g of the product of the first step and soak it in 32ml, 0.005mol / L chloroplatinic acid aqueous solution, overnight, dry at 110°C for 10 hours, and roast for 3 hours to obtain Pt / WO 3 / ZrO 2 -γ-Al 2 o 3 Supported solid acid catalyst 20.05g.

Embodiment 2

[0039] The difference from Example 1 is that the H 8 N 2 o 4 W solution is replaced by sulfuric acid solution, other reaction conditions are the same, and finally Pt / SO 4 2- / ZrO 2 -γ-Al 2 o 3Supported solid acid catalyst.

Embodiment 3

[0041] The difference with Example 1 is that the ratio of the chloroplatinic acid aqueous solution to the first step product is different, and the product 20g of the first step is immersed in 32ml, in the 0.001mol / L chloroplatinic acid aqueous solution

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com