Mercaptopropyl polysiloxane with photoreaction activity and preparation method thereof

A technology of mercaptopropylene polysiloxane and photoreactivity, which is applied in the field of mercaptopropylene polysiloxane and its preparation, can solve the problems of poor compatibility of acrylates, achieve fast reaction speed and improve mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

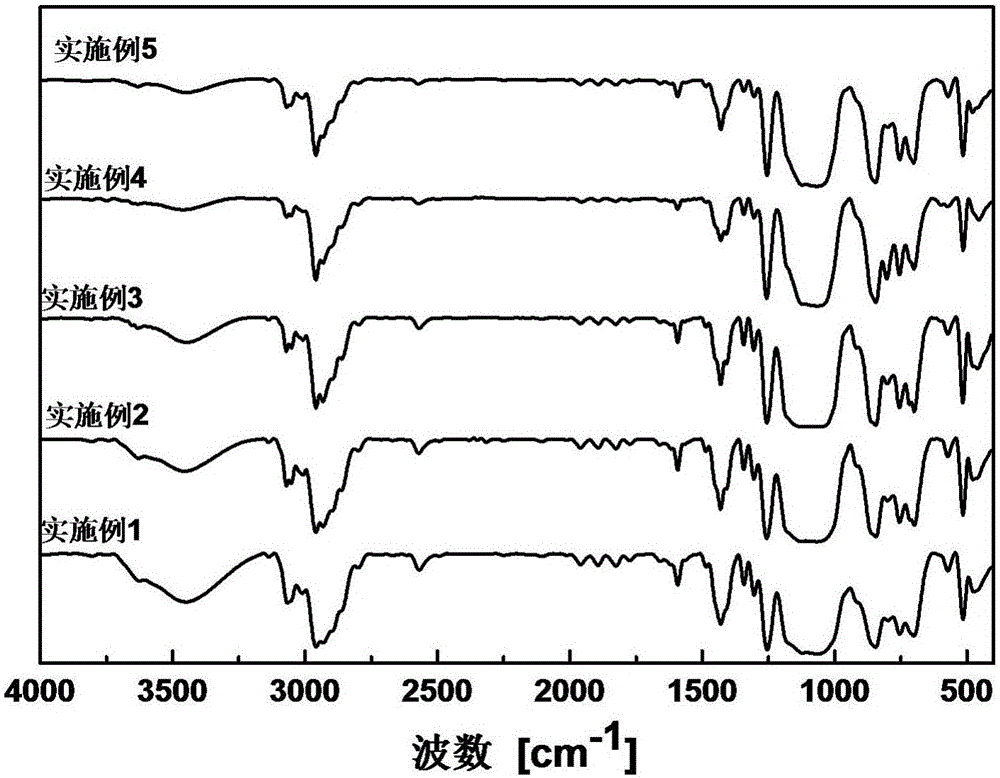

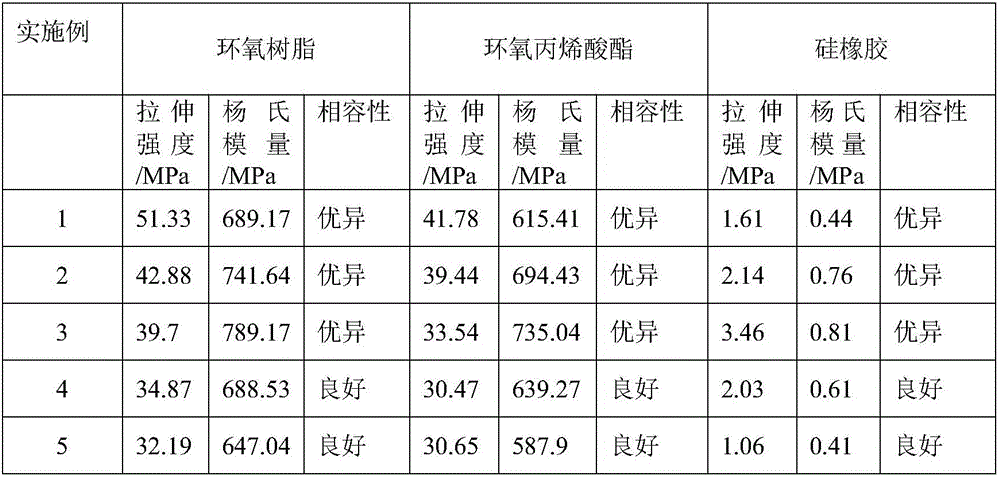

Embodiment 1

[0031] First add 70g of water, 35g of ethanol, and 4g of concentrated brine into the flask, then add 30g of hexamethyldisiloxane into the above solution, then add 150g of mercaptopropyltriethoxysilane, 100g of phenylmethyldimethoxy Diethyldiethoxysilane and 75g of diethyldiethoxysilane were added dropwise to the above-mentioned prehydrolysis solution, and then co-hydrolysis-polycondensation reaction was carried out at 60°C for 4.5h, and the reaction system was separated to obtain mercaptopropylene polysiloxane, which was used Wash with 70% ethanol aqueous solution for 3 times, and finally vacuumize at 120° C. to remove residual solvent and low boilers to obtain mercaptopropylene polysiloxane with a yield of 85.35%.

[0032] After testing, the molar ratio of the mercaptopropyl segment, the phenyl segment and the dialkyl segment in the obtained mercaptopropyl polysiloxane molecule is 0.63:0.55:0.43.

Embodiment 2

[0034] First add 90g of water, 50g of ethanol, and 5.5g of concentrated brine into the flask, then add 50g of hexamethyldisiloxane into the above solution, then add 100g of mercaptopropylmethyldimethoxysilane, 100g of diphenyldimethoxysilane Add methoxysilane and 50g dimethyldiethoxysilane dropwise to the above pre-hydrolysis solution, then co-hydrolyze-polycondense at 65°C for 4 hours, separate the reaction system to obtain mercaptopropylene polysiloxane, Wash with 70% ethanol aqueous solution for 3 times, and finally vacuumize at 110° C. to remove residual solvent and low boilers to obtain mercaptopropylene polysiloxane with a yield of 82.46%.

[0035] After testing, the molar ratio of the mercaptopropyl segment, the phenyl segment and the dialkyl segment in the obtained mercaptopropyl polysiloxane molecule is 0.55:0.41:0.34.

Embodiment 3

[0037] First add 45g of water, 20g of ethanol, and 2.5g of concentrated brine into the flask, then add 25g of hexamethyldisiloxane into the above solution, then add 94g of mercaptopropyltrimethoxysilane, 50g of tetramethyltetraphenylcyclo Tetrasiloxane and 60g of diisopropyldimethoxysilane are added dropwise to the above-mentioned pre-hydrolysis solution, and then co-hydrolysis-polycondensation reaction is carried out at 70°C for 3 hours, and the reaction system is separated to obtain mercaptopropylenepolysiloxane , washed 3 times with 70% ethanol aqueous solution, and finally vacuumed at 130° C. to remove residual solvent and low boilers to obtain mercaptopropylene polysiloxane with a yield of 83.64%.

[0038] After testing, the molar ratio of the mercaptopropyl segment, the phenyl segment and the dialkyl segment in the obtained mercaptopropyl polysiloxane molecule is 0.48:0.37:0.34.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com