Composite anchor, pipeline connection device using the anchor, and installation method thereof

An anchoring body, anchoring technology, applied in the direction of pipes/pipe joints/pipe fittings, through components, mechanical equipment, etc., can solve the problems of increased manufacturing costs, long installation time, increased production costs, etc., to avoid insufficient tensioning force, improve The effect of improving installation efficiency and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

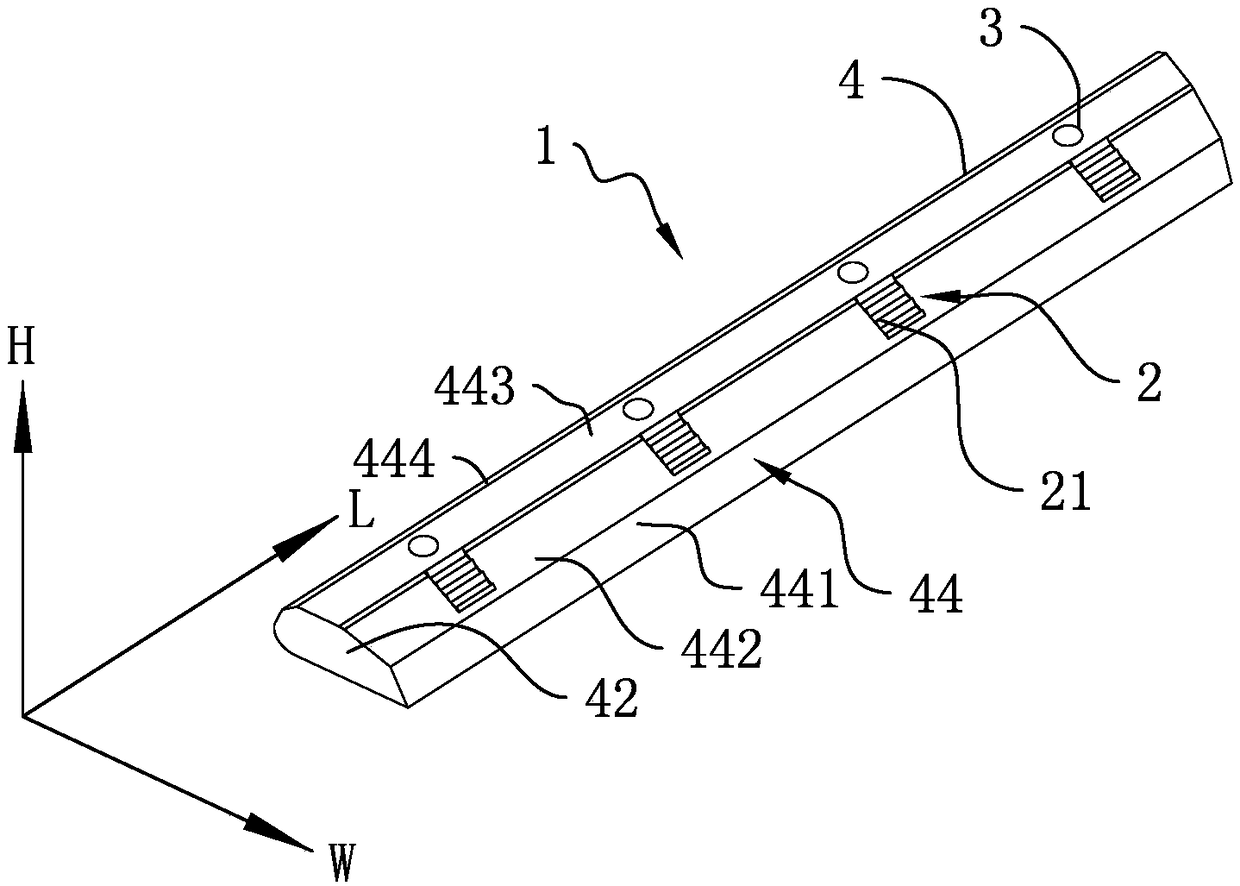

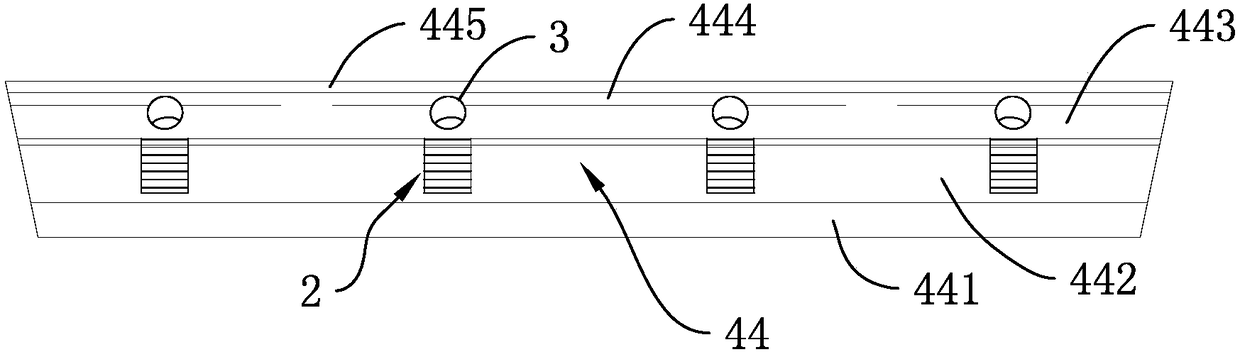

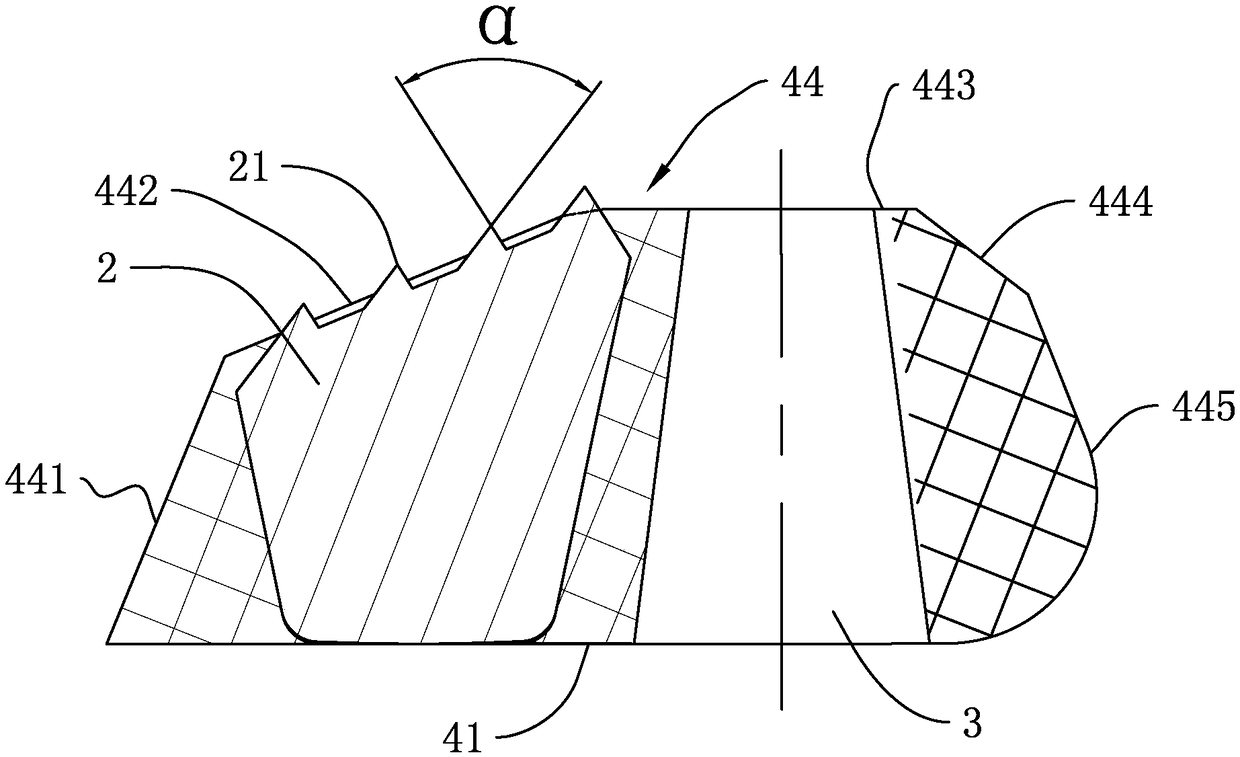

[0033] like Figure 1 to Figure 3As shown, the composite anchor 1 of the present invention includes the elastic body 4. In order to obtain a proper deformation effect, the Shore hardness of the elastic body 4 is 40HA-90HA, preferably 55HA-70HA. The elastic body 4 is a straight polyhedron with a wide bottom and a narrow top. Its bottom surface 41, left end surface 42, and right end surface are all planes, and the top surface 44 is a curved surface formed by zigzags connecting planes and planes. Wherein, the bottom surface 41 is an isosceles trapezoid, and the top surface 44 includes a front connection plane 441 connected with the front edge of the bottom surface 41, a transition plane 442 connected with the front connection plane 441, a horizontal plane 443 connected with the transition plane 442, and a horizontal plane 443 connected with the front edge of the bottom surface 41. Connected transition bevel 444 . The transition slope 444 is connected to the rear edge of the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com