Battery module

A battery module and battery assembly technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of low heat dissipation efficiency and high noise, and achieve the effects of improving heat dissipation performance, improving efficiency, and effective spring constant.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with specific embodiment:

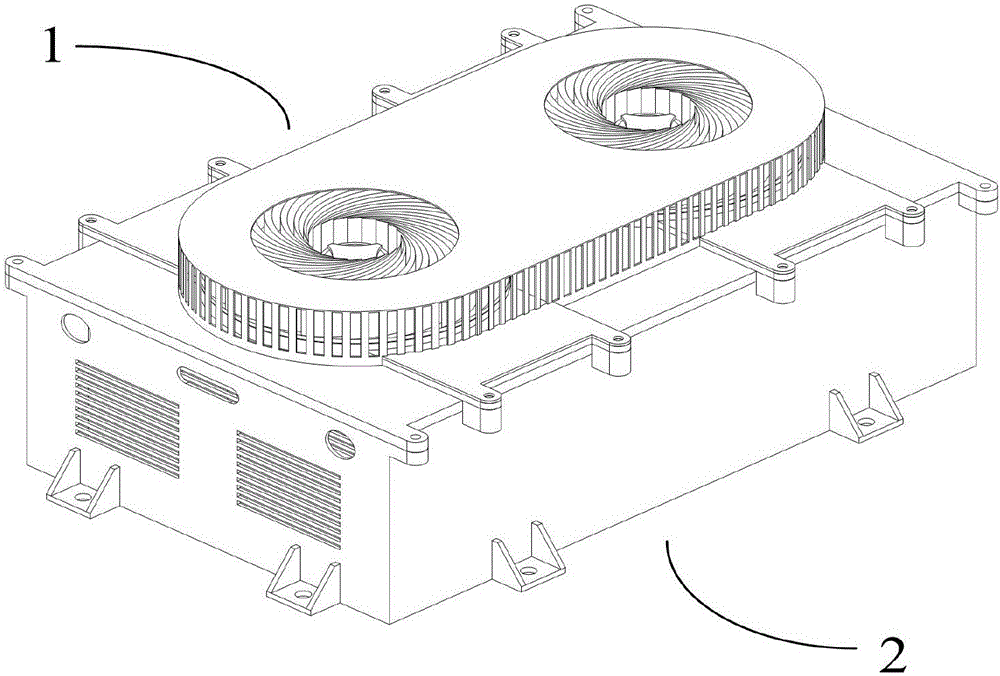

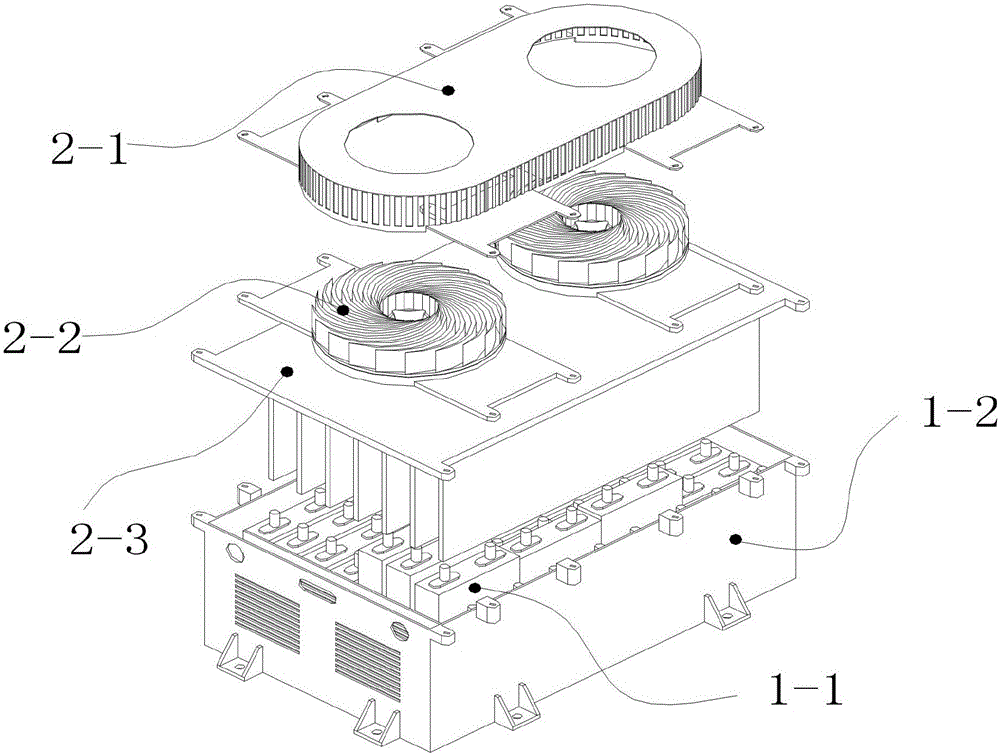

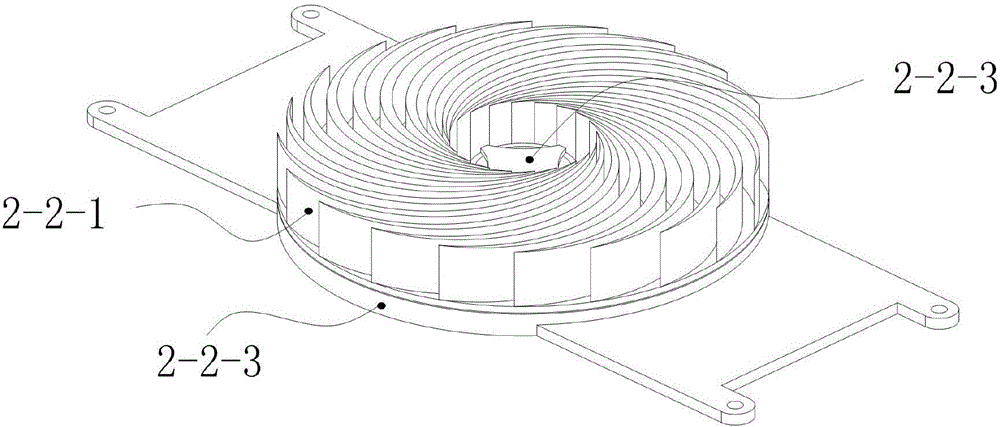

[0028] See attached Figures 1 to 2 As shown, a battery module described in this embodiment includes a battery assembly 1 and a heat dissipation assembly 2 for dissipating heat for the battery assembly 1. The battery assembly 1 is composed of a power battery 1-1 and a battery box shell 1-2 composition, the power battery 1-1 is placed inside the battery box shell 1-2 and arranged neatly according to the row structure, the heat dissipation assembly 2 includes a Sandia radiator shell 2-1, a Sandia radiator 2- 2 and the vacuum chamber soaking plate 2-3, wherein, the Sandia radiator 2-2 is set inside the Sandia radiator shell 2-1 and is closely attached to the top of the vacuum chamber soaking plate 2-3, and the vacuum chamber is The hot plate 2-3 is inserted into the gap between the power batteries 1-1, and is in close contact with the surface of the power battery 1-1; the Sand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com