Silicified microcrystalline cellulose and preparation method thereof

A technology of microcrystalline cellulose and silicification, which is used in pharmaceutical formulations, medical preparations with non-active ingredients, and pill delivery. , good fluidity and compressibility, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

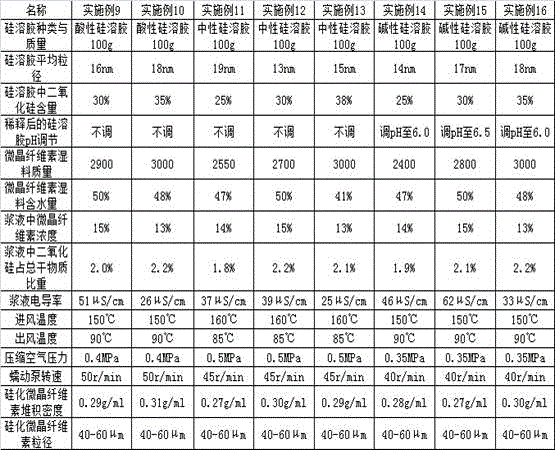

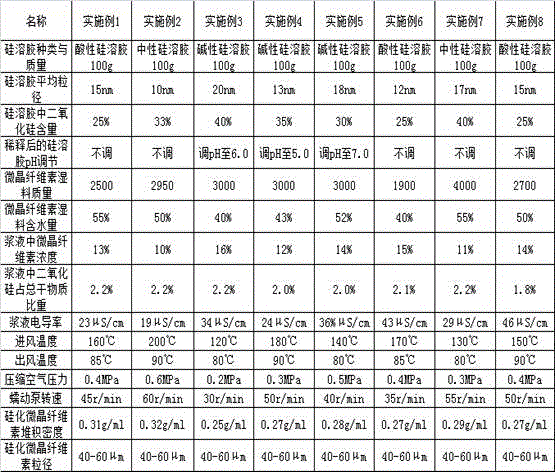

Examples

Embodiment 1

[0030] First dilute 100g of acidic silica sol with an average particle size of 15nm and a silica content of 25% (produced by one-step dissolution of simple silicon, the same below) with pure water, and then add 2500g of silica sol with a water content of 55% to the diluted silica sol % of microcrystalline cellulose wet material, homogenized and filtered to obtain a slurry with a mass concentration of microcrystalline cellulose of 13%, a proportion of silicon dioxide in the total dry matter of 2.2%, and a conductivity of 23 μS / cm.

[0031] Finally, the slurry is dried by air-flow two-fluid spraying and then sieved to obtain silicified microcrystalline cellulose with a bulk density of 0.31 g / ml and a particle size of 40-60 μm. The air inlet temperature of the air-flow two-fluid spray drying is 160°C, the outlet air temperature is 85°C, the compressed air pressure is 0.4MPa, and the speed of the peristaltic pump that transports the slurry to the atomizing nozzle is 45r / min.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com